Rebar Threading Machines(Automatic Type)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Rebar Threading Machines(Automatic Type)

Model No. : S-50A,Compressor Clamp Head/S-50E Motor Clamp Head

Size: 150x80x120(LxWxH,cm)

Weight:S-50A,400Kgs;S-50E 450kgs

Item | S-50A/S-50E | |

Motor | kind of motor | Squirrel - Cage Induction Motors ( SCIM ) 3-PHASE |

Design Standards | IEC 60034, IEC 60072 | |

Voltages | 380V | |

Frequency | 50Hz or 60Hz | |

Output Range | 7.5KW | |

R.P.M. (Syn.) | 1440 min | |

Time Duty | Continuous. S1 , S.F.:1.0 . | |

Protection Enclosure | Totally Enclosed ( IP 55 ) . | |

Cooling Method | Self External Fan, Surface Cooling ( IC 411 ) . | |

Gear Speed Reducer | MODE | BWY |

Ratios | 1:19 | |

Lubricate | ISO EP68 Gear Oil | |

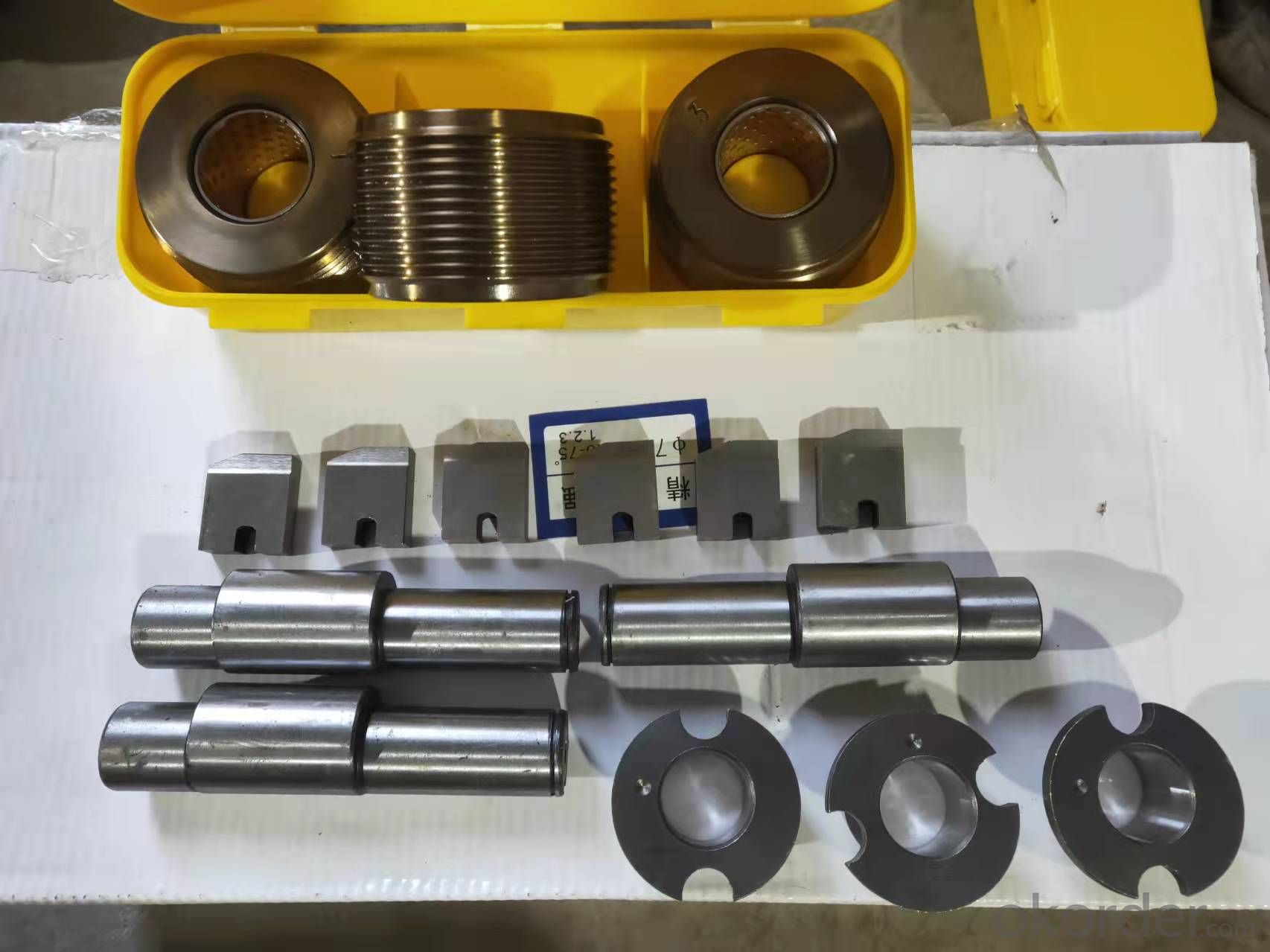

Cutter Head | Steel Bar Rang(mm) | 16-40mm |

Screw Max Length(cm) | 275px standard, 750px screw for Max 32mm Steel Bar | |

Cutting Lubrication | Coolant Circulation by Water Pump | |

Cutter Using times | 6000-8000 times | |

Clamp Head | Clamp head Driven | S-50A by Air/S-50E by motor |

Accessories | Emergency Stop Bottom | |

Air Compressor 0.6/min and Air Tube for S50A for 4 Nos machine | ||

Consumption Parts | Part No-001 | Die-head Threading,6000-80000 times |

Part No-002 | Rib Removing Cutter,3000-4000 times | |

Part No-003 | Eccentric Shaft,Each half year | |

Reducer Lubrication Instruction:

Check and fill the lubricate before running the machine, first lubricate maintenance after 300 hours running and 1000 hours or half year after first lubricate maintenance.

Lubricate oil:ISO EP68 or 150 Gear oil, 1.5 Liter

Please check before running the machine , no any lubricate oil filled by the manufacturer for safety delivery purpose.

- Q: Grease for electric tools

- Long acting high temperature grease for imports. I only sell the grease such to do the diangao.

- Q: What made electric tools Gendiao coffee table

- In order to root production materials, mainly is the root wood. In addition, some auxiliary materials, such as glue (glue, latex), paraffin wax, lacquer (varnish, lacquer) etc.. When you need to paint, you also need the pigment you need.

- Q: Power tool for diamond

- Diamond is commonly known, known as water diamonds, diamonds referred to as diamond. Home: air conditioning hole, water heater, lampblack machine hole hole, Yuba hole, fan hole, hole, hole on the gas pipeline, leak, toilet hole, hole, hole, heating pipe line wall hole, chimney hole and other specifications, diameter with 1mm- with 25mm hole drilling directly. Continuous drilling is also available, as required.

- Q: Know the power tool type and how to find the corresponding carbon brush

- Because most electric tool is the copy of foreign or domestic large and well-known brand products, such as Japan's MAKITA 4100 stone cutting machine with 303 carbon brush, Zhejiang 100 angle grinder with 51 carbon brush, 26 hammer with 21 brushes, just look for is the imitation of the machine, with the original machine manufacturers to see there is a Book brush type in the above, a model to sell electric tool shop, or ask sell electric tools, all know, remember do not buy too cheap, cheap ordinary machine if you just, if imported or domestic good machine, or more than 1000 watts of power to machine. With the original or high quality, because the brush has a direct impact on the rotor (or motor) life

- Q: What are the inspection and use of power tools?

- The general use of the old tools electric insulation is relatively poor, the coil is not in the optimal condition, the wear of each bearing will have error, the seal will also have certain safety will wear, resulting in poor. Therefore, only after a rigorous test, determine the power tools in good working performance, you can continue to use.

- Q: How to buy power tools? Such as a pistol drill

- To use objects to choose, drill iron not more than 10mm, more than 10mm or with a drill, safety.

- Q: How to connect the sleeve head and the power tool?

- The sleeve head is normally used for an electric wrench, and the electric wrench is connected with a common hole of the sleeve head, and the socket head of different sizes can be changed at any time.

- Q: How do you change 110 volt power tools to 220 volts?

- It's a waste of time and effort to change that. First change the control unit, then change the motor, the motor should be redesigned. After the change, it is better to buy a home made.

- Q: Are the metal housings of the two types of power tools grounded?

- Class II tools, that is, insulated structures, all double insulated power tools. Its specified voltage is more than 50VClass II tools are not allowed to set ground devices. Generally insulated enclosures.

- Q: Why should the power tools be powered off when the people leave?

- When the operator leaves the power tools, the power failure should be handled in time. 1, electric tools can save electric energy consumption; 2, to prevent misuse of non professional personnel, the accident harm to people, equipment; 3, prevent the sun and rain, caused by electrified equipment leakage, short-circuit or fire; 4, eliminate idle people out of curiosity, caused by electric shock accident.Safety in order to produce, production must be safe.

Send your message to us

Rebar Threading Machines(Automatic Type)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches