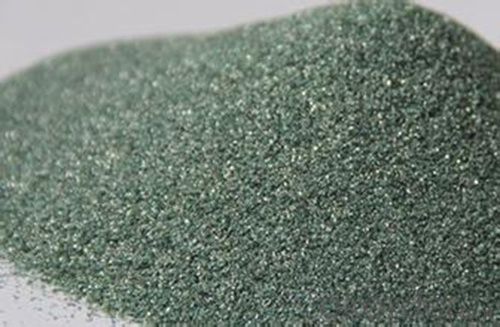

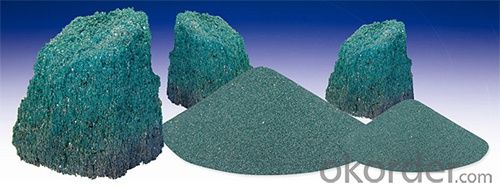

Raw Materials for Refractory:Silicon Carbide Green Abrasives & Refractory Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GREEN SILICON CARBIDE(GC)

Green silicon carbide is characterized by strong grinding efficiency and good heat-conductivity. Its hardness and strength are higher than fused alumina.

Applications:

1. Used to grind hard and brittle metal alloys, non-ferrous metals and non-metallic

materials like jewels,optical glass and ceramics.

2. Suitable for manufacturing vitrified wheels and belts, organic wheels and sheets.

3. Applied to refractory industry.

4. Powder of GC is also used as wire sawing semi-conductor raw materials.

Chemical Composition:

Type | Grit | Chemical Composition(%, by weight) | ||

SiC(≥) | F.C(≤) | Fe2O3(≤) | ||

GC | F20-F90 | 99.0 | 0.20 | 0.20 |

F100-F150 | 98.5 | 0.25 | 0.50 | |

F180-F220 | 97.5 | 0.25 | 0.70 | |

F240-F600 | 97.0 | 0.30 | 0.70 | |

F800-F1200 | 95.5 | 0.40 | 0.70 | |

P12-P100 | 99.0 | 0.20 | 0.20 | |

P120-P150 | 98.5 | 0.25 | 0.50 | |

P180-P220 | 97.5 | 0.25 | 0.70 | |

P240-P1000 | 97.5 | 0.30 | 0.70 | |

P1200 | 95.5 | 0.40 | 0.70 | |

GC-B | F20-F90 | 98.5 | 0.25 | 0.25 |

F100-F150 | 98.0 | 0.30 | 0.55 | |

F180-F220 | 97.0 | 0.30 | 0.80 | |

F240-F600 | 96.5 | 0.35 | 0.80 | |

F800-F1200 | 94.5 | 0.45 | 0.80 | |

GC-P | P12-P100 | 98.5 | 0.25 | 0.25 |

P120-P150 | 98.0 | 0.30 | 0.55 | |

P180-P220 | 97.0 | 0.30 | 0.80 | |

P240-P1000 | 96.5 | 0.35 | 0.80 | |

P1200 | 94.5 | 0.45 | 0.80 | |

Note: Special requirements can be satisfied by negotiation.

- Q: How many kinds of refractory materials are there in the EI?

- I suggest that you contribute articles to foreign SCI journals for the odds are better, and generally the articles that fill the bill will not be rejected. The traditional refractory materials can contribute to EI journal. If being rejected by EI journal, you can also contribute to Russia's journal Industrial Ceramics and Refractories. I didn't contribute to the Journal of Wuhan University of Science and Technology, the receiving cycle is almost 3 to 4 months. Though the impact factor is low, domestic EI journal is not so good, it is still SCI journal. This is my own experience, please take my advice. The best journals are the Journal of the American Ceramic Society and the Journal of the European Ceramic Society, I heard that they are not bad. But the best domestic EI refractory material journal is the Journal of The Chinese Ceramic Society. It is very long, but if it belongs to your university, it is another pair of shoes. Journals now all want to have materials about functional ceramics, and they don't want Chinese articles, if your English is not well enough, you can choose Ceramics International and Japan Ceramics but they have strict manuscripts reviewing standards.

- Q: What requirements should refractory materials meet?

- Ladle is an necessary equipment to undertake molten steel and continuous casting. As many kinds of steel needs to be processed in the ladle, including argon blowing tempering, alloy composition fine-tuning, refining dusting and vacuum processing, working conditions of the ladle lining have worsened. Their working conditions are as follows. (1) The temperature of molten steel is higher than mold casting ladle. (2) the molten steel stays longerin the ladle. (3) ladle lining are subjected to volatilization and agitation of molten steel under high temperatures and in vacuum. (4) The impact on the lining when undertaking steel liner when the impact effect. Therefore requirements of the ladle refractories are as follows: (1) It can resist high temperature. Molten steel should be able to withstand high temperatures without melting. (2) It can resist thermal shock and can withstand molten steel without cracking and spalling. (3) It can resist slag erosion. The ladle should be able to withstand the erosion of lining caused by slag and alkalinity changes of slag. (4) it should have sufficiently high temperature mechanical strength to withstand the agitation and scouring of molten steel. (5) lined should have certain swelling property so that lining will be united as a whole under the effect of hyperthermal molten steel.

- Q: Who knows what is the standard of insulation material whose fire proof is level A?

- Fire insulation materials of level A is non combustible building materials, and does not have any burning material. Level A1: single inorganic non combustible, no open flame. Level A2: A2 level: composite organic non combustible, that is, composite materials, non flammable, smoke volume should reach the standard.

- Q: How to calculate the thickness of choosing refractory? Such as steel ladle should choose what kind of refractory and using what thicknes?

- I feel the concrete thickness should depend on the experience and the actual situation. As for the specific method, I also can't say too accurately. If it's ladle, it generally chooses alumina magnesia castable.

- Q: Does anyone know what kind of light fireproof materials are there?

- 二, 1, Gypsum plaster board With the building plaster as main raw material, gypsum plaster board is a kind of processed plate made by a special board for protective with an addition of additives and fibers as board core. Gypsum plaster board is characterized by light weight, sound insulation, heat insulation, strong processing performance and simple construction method. 2, Gypsum block Gypsum block is a kind of lightweight building gypsum product which is mainly made of building gypsum, and by adding water, stirring, casting and drying. During the process, , the fiber reinforced materials or light aggregates are allowed in, and the foaming agent can also be added. It has many advantages, such as sound insulation and fire prevention, convenient construction and so on. It is a kind of new and healthy wall material which produces low carbon, enhances environmental protection, and caters to the the times. 3, Fly ash brick is a new type of wall material, and bulk density is one of the main technical indexes. The weight of bulk density can be controlled according to the need of construction and adjustment of technical formula. The dry bulk density of the fly ash brick is about 1540 to 1640 kg / m 3, slightly lighter than the clay brick (1601800 kg /m 3). The flexural and compressive strength of fly ash brick is mainly determined by the production process, the formula and the hydrothermal synthesis reaction mode as well as the need of construction. According to the standards of architectural material industry (JC239 - 2001) released by People's Republic of China, the average value of the flexural strength is 2.5 ~ 6.2Mpa, compressive strength is between 10 ~ 30Mpa. I hope this will be helpful to you

- Q: What's the definition of fire endurance of the fire-resistant coating for steel structure?

- 1. Fire endurance. Conduct fire resistance test of any building component according to the standard time-temperature curve, and the time when it is subjected to the fire to the time when it loses support capability or fire insulation function or its integrality is destroyed is referred to fire endurance. 2. Steel has relatively low fire endurance which is usually 0.25h only, namely 15 minutes; 3. Of steel structure buildings, steel can be used as beams, pillars, etc. but its fire endurance is not enough (usually these components have higher requirement on fire endurance, and take pillar as an example, it is usually demanded that the fire endurance should be 2-3h), and under this condition, it needs to brush fire retardant coating so as to raise the fire endurance. As to the specific quantity or types of the fire retardant coating, it is decided upon the actual conditions. In short, the building material needs to meet the required fire endurance of the buildings.

- Q: What materials are needed to make the amorphous refractory bricks?

- Amorphous refractory brick is composed of a certain proportion of aggregate and powder, a binder and an additive, and can be directly used without high temperature firing.

- Q: How to make fire resistant materials for building stoves

- Why Qianjun game protected mode can attack the foreign baby call

- Q: how is the high-temperature flame-retardant fibre board?

- ------ Different category of high temperature materials including refractory and heat-resistant material, inorganic compounds, high-molecular polymer. refractory usually refers to an inorganic material that can endure temperature above 1580 ℃ . They are for building kiln, combustion chamber and other buildings that require heat resistance materials. It is generally made of quartz sand, clay, magnesia mineral, dolomite.

- Q: What are the differences between intensive refractory busway and other busways?

- Compact busway is named after its structure, especially referring to busway which is closely laminated between phases and between phase and shell and use thin insulating material to achieve the insulation result. Fire-resistant busway is named after its uses, just as its name implies, for higher fire safety requirements need busway of higher fire resistance level. The structural style of fire-resistant busway can be intensive and of air type, depending on what material it use to resist fire, so there is no direct link between them, but there is a included relationship.

Send your message to us

Raw Materials for Refractory:Silicon Carbide Green Abrasives & Refractory Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords