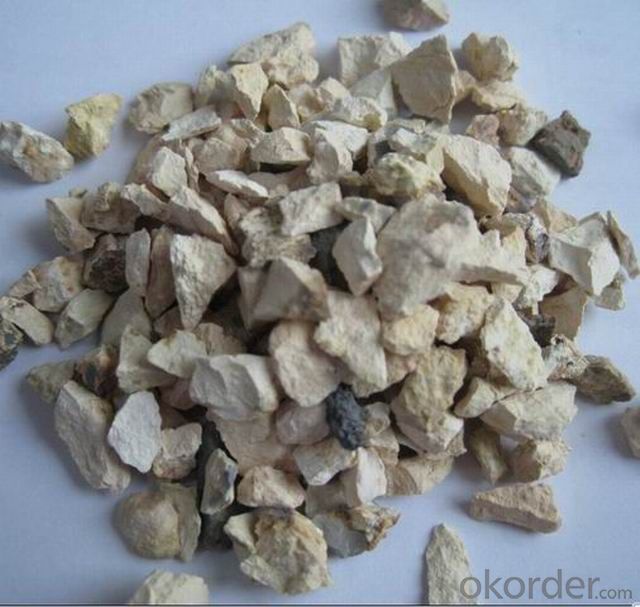

Raw Materials for Refractory:Hot Sale 80% China Calcined Bauxite Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale 80% China calcined bauxite price

Product Description

Introduction

There are several different models of calcined bauxite,we own have three bauxite quarry,and can produce 5000 tons bauxite per month.

The price of calcined bauxite based on the quantity and the type, pls kindly go through the following presentation,and just tell me which type you want to buy, what is the application and how many, then we can quote you correctly!

Application of calcined bauxite:

Bauxite is widely apply to refractories, aluminum silicate refractory fiber, precision casting, alumina smelting industry,bauxite cement, etc.

Technical indexes

Technical Indexes of calcined bauxite

Item | SNR90 | SNR88 | SNR87 | SNR85 | SNR80 |

| Al2O3% (min) | 90 min | 88 min | 87 min | 85 min | 80 min |

| SiO2% (max) | 3.5 | 5.5 | 7 | 8 | 10 |

| Fe2O3% (max) | 1.5 | 1.6 | 1.8 | 2 | 2.5 |

| TiO2% (max) | 3.8 | 4 | 4 | 4 | 4 |

| CaO+MgO % (max) | 0.35 | 0.4 | 0.4 | 0.4 | 0.5 |

| K2O+ Na2O % (max) | 0.35 | 0.4 | 0.4 | 0.4 | 0.5 |

| Bulk density(gm/cc) (min) | 3.35 | 3.25 | 3.2 | 3.1 | 2.9 |

| Moisture (max) | 0.3 | 0.3 | 0.3 | 0.4 |

0.5 |

| Item name | RKB-85 | RKB-86 | RKB-87 | RKB-88 | RKB-90 |

| Al2O3 % min | 85 | 86 | 87 | 88 | 90 |

| Fe2O3 % max | 2.0 | 1.8 | 1.8 | 1.8 | 1.6 |

| TiO2% (max) | 4.0 | 3.8 | 3.8 | 3.8 | 3.8 |

| CaO+MgO % (max) | 0.3 | 0.25 | 0.25 | 0.25 | 0.25 |

| K2O+ Na2O % (max) | 0.5 | 0.45 | 0.45 | 0.45 | 0.45 |

| Bulk density(gm/cc) (min) | 3.10 | 3.15 | 3.25 | 3.30 | 3.40 |

| Moisture (max) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| SiO2% (max) | 9.0 | 8.0 | 7.0 | 6.0 | 4.0 |

| Shipment | Jumbo | Jumbo | Jumbo | Jumbo | Jumbo |

| Package | By sea | By sea | By sea | By sea | By sea |

Our service of calcined bauxite

5.1:Quality assurance,CX REFRACTORY use high grade raw material and do strict inspect during the whole procession.All the products adopt GB,ISO,ASTM,BS,JIS and DIN standard as per requirement.

5.2:Provide professional designing solution,Construction guidance and any consulting

5.3:Price Advantage,provided by manufacturer directly,save much intermediate fees.

5.4:Professional team:specialized in refractory production since 1986,with advanced technology and vast experience.

- Q: What's the texture of refractory for the hearth of reverberatory?furnace? ?

- High alumina brick; you can use zircon brick under the temperature above 1700? ;may i use mullite bricks under the temperature from 1400 to 1700? you can use clay brick and heavy corundum brick under the temperature of below 1400 degrees, question closely: what's the usage temperature of reverberatory?furnace? < pre accuse = "qRA" > is there someone use refractory fiber?

- Q: How to solve the shell, the crack problem of refractory material in the process of forming.

- Pressure mode and number of pressure control "spallation". 2, multiple pressure, pressure degree and discharge way: 1, reduce friction, choose appropriate, than big pressure disposable pressure produced by the plastic deformation, allocate reasonable grading, internal and external friction, reduce billet particles and high die wall bright. 4.--- solve the light one firstly. --moisture content being too high easily cause spallation - the compressibility of water is small and have certain elasticity, appropriately to extend the pressuring time is beneficial. The material can produce large plastic deformation under the effect of continuous load. The right amount of lubricant. - body under the condition of less pressure but long effect time molding. Mould structure is reasonable and improve billet natural stacking density. 5.3, measures to improve the unburned brick molding quality. Many times continuously pressure relief is better than one-off sudden unloading, and controlling the appropriate moisture content;- - is beneficial to air overflow.

- Q: Who knows the model of fireproofing materials?

- Models of fireproofing material: PC 6555 Bayer 6555 fireproofing PC 6557 Bayer 6557 fireproofing PC 6485 Bayer 6485 fireproofing PC 6385 Bayer 6385 fireproofing PC 6265 Bayer 6265 fireproofing PC 2865 Bayer 2865 fireproofing PC 4610 Dow 4610. Hope my answer will be helpful to you!

- Q: How to make use of waste refractory materials whose main elements are alumina and mullite?

- Crushing and pressing refractory bricks, or refractory parts . Such as welding positioner tracks use disposable tools.

- Q: What are the fire resistances of grc partition panels?

- A-level fireproofing which can last for 4 hours.

- Q: What are the raw materials of refractory?

- Of course, different types have different raw materials: Magnesite (the electric?smelting: alkaline refractory, magnesia-carbon bricks, alkaline, high-purity) + crystalline flake graphite + phenolic resin + additive (silicon powder, aluminite powder, silicon carbide powder, or high-temperature asphalt,etc.) , acidic refractory: The neutral is not easy to answer. such as. You can check out the classification, such as

- Q: Firing high temperature kiln of refractory and internal temperature being as high as 1600 ℃, metal heat exchanger can't use, how to do?

- 1>3>。 When metal heat exchanger is in 700 ℃, it must process high temperature protection, mixed cold wind or cold blast to protect heat exchanger. So this will waste a lot of energy; The comparison of high temperature resistant ceramic heat exchanger using temperature is 1350 ℃ to 1450 ℃; metal heat exchanger using temperature 700 ℃; heat utilization comparison of ceramic heat exchanger can be placed in 1350 ℃ or higher (highest available to 1450 ℃); the oxidation resistance, a very short time will burn out;2 >, waste heat recovery rate is high. Replacing the metal heat exchanger in high temperature and corrosion environment; Comparative ceramic heat exchanger can be used under the condition of 1350 ℃ for a long time. Let's make a comparison, if it is a refractory material industry. <, ceramic heat exchanger is simply won't appear, under the condition of equal to ceramic heat exchanger using, energy saving effect is best, can exchange for the high temperature. <. Ceramic heat can be placed on the nearest of exchanger flue outlet . <, and metal heat exchanger put in place contrast to the ceramic heat exchanger. In the process of using metal heat exchanger, if this situation happens, you can consider the ceramic heat exchanger. Temperature difference is between 650 ℃ to 750 ℃. If the metal heat exchanger is placed in normal place where ceramic heat usually put;The service life comparison: since ceramic heat exchanger with high temperature resistance, this partly replace metal heat exchanger. What's more, energy-saving rate is also different. Metal heat exchanger can be placed in 700 ℃ or less;4 >, corrosion resistance, its application effect is very different. So the metal-heat-exchanger's heat-resistant temperature is high and the service life is the countless times of metal heat exchanger. The place with highest temperature does not need high temperature protection.

- Q: How many external wall thermal insulation fireproof material are there

- External wall thermal insulation materials are generally divided by the burning grade, into class A, B grade. Grade A is non combustible material, grade B is combustible material. Class A which can be divided into thermal insulation mortar, bakelite plate, rock wool plate, foam cement plate etc.. Insulation mortar is relatively good, easy for construction, convenient, low cost, but its production process is too simple, so it is prone to fake. I recommend you to find a large manufacturing factory that posses complete procedure, for example, provincial production record, the provincial use record, municipal record, tset report at or above the provincial level, state fire proof report, design drawings of office building. product will not be safe if there is a lack of any of these documents. Burning level for henolic is uaually class B, but class A2 can be reached if a thin layer of mortar is applied on the suface,(A1 is the highest level of fire safety),intensity of phenolic is not high, finger pressing will leave a pit on it. if classified according to kilogram, raw material differs greatly every 10 kilogram. Rock wool is also classified by kilogram, general using 150kg wool. Rock wool are now comprounded with average strength. It will easily absorb water, having trouble applying paints. Foam cement strength is not high, easy to absorb water, It is not resistant to falling. It costs low, only used unless little profit can be made, Do not use it if worrying accidents would happen. These materials can be firstly burned, The palce the sample into water to see if it will dufuse at last. External wall should stand up to wind and rain. In terms of thermal insulation, they are almost the same, shows little differences on design thickness.

- Q: What's the commonly used refractory material for ladle?

- 1. According to the refractoriness, it can be classified as follows: common refractory: 1580℃ ~ 1770℃; high grade refractory: 1770℃ ~ 2000℃; superrefractory: 2000 ℃; 2. According to the shape and demension of the product, it can be classified as follows: standard form : 230mm×113mm ×65mm of no more than four measuring scale, (demension ratio) Max: Min

- Q: What are the grades of refractory exterior wall thermal insulation materials?

- Classification of fire rating of extrior thermal insulation materials 1, According to national standard GB8624-97, the combustion performance of building materials are divided into the following grades A level: Incombustible building materials: Materials hardly burn. B1 class: Flame-retardant building materials: Flame-retardant material has good flame resistance. In case of fire in the air or at high temperature, it is difficult to catch fire and the fire will not spread quickly. And when the combustion source is removed, the burning will stop immediately. B2 Class: Combustible building materials: Combustible materials have a certain flame retardancy. In case of fire in the air or at high temperature, it will immediately burst into flames and it is easily to spread fire, such as wooden column, wooden roof truss, wooden beams and wooden stairs, etc. B3 level: Inflammable building materials: It has no flame retardant effect, and it is extremely inflammable, and the risk of fire is high. Classification of exterior wall thermal insulation materials according to fire rating: 1. Thermal insulation materials with A-level combustion performance Rock wool, glass wool, foam glass, foamed ceramic, foam cement, hole-closed perlite, etc. 2, Thermal insulation materials with B1-level combustion performance: Extruded polystyrene board (XPS) after special treatment / polyurethane (PU) after special treatment, phenolic aldehyde, gelatine powder polystyrene granule, and etc. 3. Thermal insulation materials with B2-level combustion performance: Molded polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc.

Send your message to us

Raw Materials for Refractory:Hot Sale 80% China Calcined Bauxite Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords