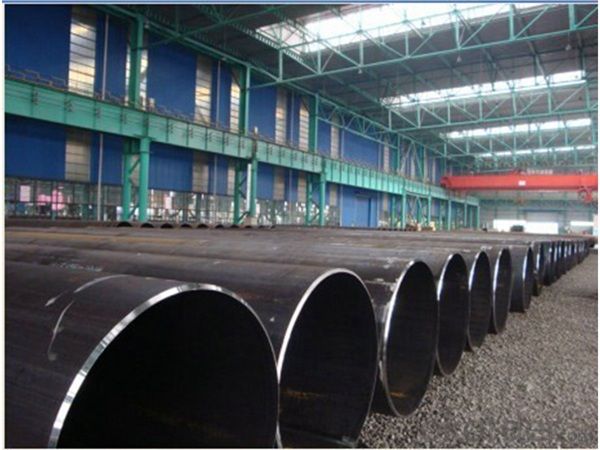

Quality Q345B straight seam pipe submerged arc welding pipe large diameter Q235 straight seam pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product information:

Straight seam welded pipe, with hot rolled or cold rolled steel plate or steel strip coil welded steel pipe in the welding equipment for straight seam welded pipe is called straight seam welded pipe.

The material:

Commonly used materials in China are Q235A, Q235B, 0Cr13, 1Cr17, 00Cr19Ni11, 1Cr18Ni9, 0Cr18Ni11Nb, 16Mn, 20#, Q345, L245, L290, X42, X46, X70, X80, etc.

X42, X46, X56, X80 and other materials are API standard materials, which are not commonly used materials of pipe materials in China.

Use:

Straight seam steel pipe is mainly used in water engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation and urban construction.

For liquid transport: water supply, drainage.

For gas transportation: gas, steam, liquefied petroleum gas.

For structure: for driving pile pipe, as a bridge;Wharves, roads, structural pipes, etc.

company production:

Our company is a new force established by the pipe industry group founded in the 1980s. Relying on a large number of core technologies accumulated by the group, as well as strict quality control, physical and chemical testing, it carries out professional pipe fitting management in strict accordance with various standards.Products are widely used in petroleum, petrochemical, chemical, thermal power, boiler, four pipelines, fertilizer, aviation nuclear power, metallurgy, shipbuilding, machinery and military fields.

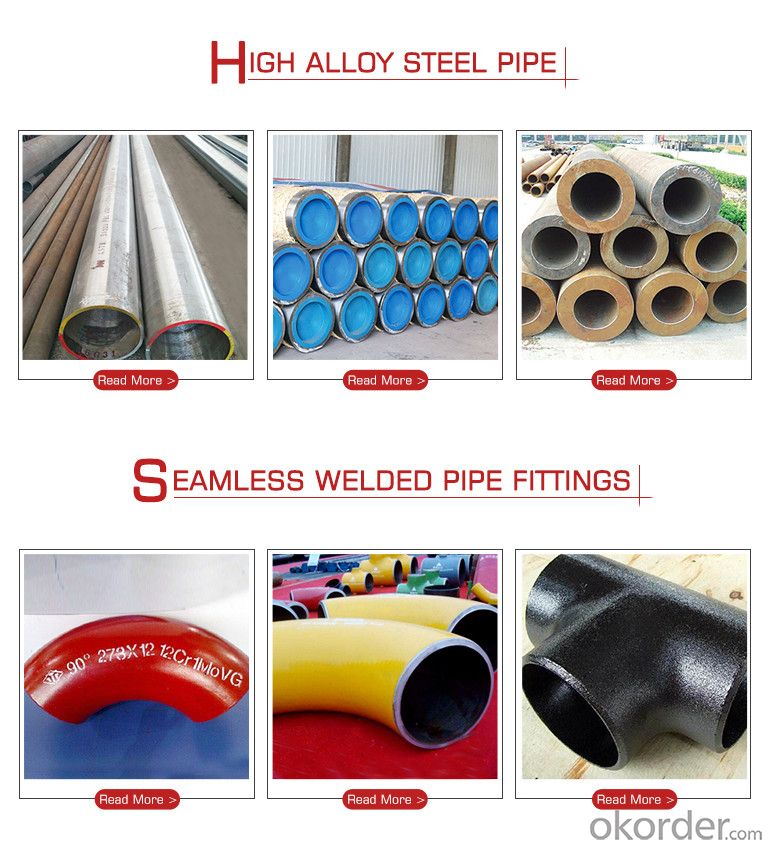

The main products of our company mainly include elbow, elbow, tee, reducing pipe, pipe cap, sharp elbow, flange, socket, forged pipe fittings and difficult pipe fittings.In addition, our company always has alloy steel tubes, seamless steel tubes for high-pressure boilers.Middle and low pressure boiler tube, low temperature steel tube, pipeline steel tube and so on after 10,000 tons.

- Q: How are steel pipes coated for protection?

- Steel pipes are coated for protection through a process called corrosion protection coating. This typically involves applying a layer of epoxy, polyethylene, or other specialized coatings onto the surface of the steel pipes. The coating acts as a barrier, preventing direct contact between the steel and any corrosive substances in the environment, thereby extending the lifespan of the pipes and enhancing their durability.

- Q: Can steel pipes be used for gas distribution?

- Yes, steel pipes can be used for gas distribution. Steel pipes are commonly used for transporting natural gas and other gases due to their high strength, durability, and resistance to corrosion. They can withstand high pressure and are suitable for long-distance gas distribution networks. However, it is important to ensure proper materials and installation techniques are used to prevent any potential safety hazards.

- Q: How do you calculate the pipe volume flow rate for steel pipes?

- In order to determine the volume flow rate of steel pipes, one must take into account the diameter of the pipe and the velocity of the fluid. The formula utilized in this calculation is Q = A * V, where Q represents the volume flow rate, A denotes the cross-sectional area of the pipe, and V represents the fluid velocity. To initiate the process, the cross-sectional area of the pipe must be determined. In the case of a circular pipe, the formula A = π * r² can be employed, where A signifies the area and r denotes the radius of the pipe. If the diameter of the pipe is provided, dividing it by 2 will yield the radius. Subsequently, the fluid velocity must be established. This can be accomplished by directly measuring the velocity using a flowmeter or by calculating it based on the properties of the fluid and the pressure drop across the pipe using the Bernoulli equation or other suitable equations. Once the cross-sectional area and fluid velocity have been determined, they can be multiplied together to ascertain the volume flow rate. It is important to maintain consistent units throughout the calculation. For instance, if the area is expressed in square meters and the velocity is in meters per second, the resulting volume flow rate will be in cubic meters per second. It is worth noting that this calculation assumes the fluid to be incompressible and flowing steadily through the pipe. If there are alterations in the fluid properties or flow conditions, additional considerations may need to be taken into account in order to accurately calculate the volume flow rate.

- Q: What are the different types of couplings used with steel pipes?

- There are several types of couplings commonly used with steel pipes, including threaded couplings, slip-on couplings, welding couplings, and flanged couplings. Each type of coupling has its own specific method of connection and is chosen based on the requirements of the application and the pipe system.

- Q: What is a valve and how is it used in steel pipes?

- A valve is a device used to control the flow of fluid or gas in a pipe system. In the context of steel pipes, valves are typically installed at specific points along the pipeline to regulate the flow, stop or start the flow, and control the pressure of the fluid or gas. These valves can be manually operated or automated, allowing for efficient control and maintenance of the steel pipe system.

- Q: Can steel pipes be used for transporting slurry?

- Steel pipes can indeed be utilized for the transportation of slurry. They find widespread application in several industries, such as mining, construction, and oil and gas, where they serve the purpose of conveying various types of fluids, including slurry. Slurry, typically comprising solid particles suspended in a liquid, primarily water, poses no challenge for steel pipes, as they possess the necessary robustness and endurance to handle its abrasive characteristics. Moreover, steel pipes exhibit exceptional resistance against corrosion, a crucial factor when confronted with slurry that may contain corrosive elements. Furthermore, the sleek interior surface of steel pipes plays a significant role in minimizing friction and ensuring the smooth and efficient flow of the slurry. In conclusion, steel pipes stand as a dependable and widely preferred option for the transportation of slurry due to their strength, durability, resistance to corrosion, and smooth inner surface.

- Q: How are steel pipes used in the construction of hydroelectric power plants?

- Steel pipes are used in the construction of hydroelectric power plants for various purposes, such as transporting water, containing and directing the flow of water, and supporting the weight of turbines and other equipment. They are typically used for penstocks, which are large pipes that carry water from the dam to the turbines, and for discharge pipes that release water back into the river. The strength and durability of steel pipes make them ideal for withstanding the high pressure and heavy loads involved in hydroelectric power generation.

- Q: What are the different types of steel pipe supports?

- Some different types of steel pipe supports include pipe hangers, pipe clamps, pipe straps, and pipe saddles. These supports are used to secure and stabilize pipes in various applications, ensuring their proper alignment and preventing sagging or movement.

- Q: What kinds of steel pipe are divided into?

- The steel pipe seamless steel pipe and welded steel pipe (tube) two categories. According to the section shape and can be divided into round tube shaped tube, round steel pipe is widely used, but there are also some square, rectangular, semicircular, hexagonal, triangular, octagonal shaped steel tube.Seamless steel pipe: seamless steel pipe is ingot or solid billet made by capillary hole, then hot, cold or cold drawing. Made of seamless steel pipe specifications with outer diameter * wall thickness mm. Number of seamless steel pipe cold and hot points of seamless steel pipe (DIAL) two categories.

- Q: Where is the difference between seamless steel pipe and welded pipe?

- Seamless steel tube is formed during rolling. Welded steel pipes need to be welded after coiling, and spiral welding and direct welding are generally used. Seamless performance is better, of course, the price is higher.

Send your message to us

Quality Q345B straight seam pipe submerged arc welding pipe large diameter Q235 straight seam pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords