PWM Solar Charge Controller and LED Constant Current Driver 20A,12/24V, LS2024100BPL

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features:

·12V/24V automatic identify or user-defined working voltage.

·Gel, Sealed, Flooded and user-defined battery type option.

·With functions of current power calculation, it is convenient to view charging and discharging energy of each day, month, year and total value.

·Wide input voltage range:DC8.0V—DC32V, compatible with 12V/24V full voltage range.

·Digital precision constant current control and the control accuracy are better than ± 2%.

·Maximum output efficiency of 95%.

·The rated output current can be adjusted at rated power and current range.

·The max output voltage can reach up to 60V

·Charge control parameter, the load control parameter and the output current value can

be set separately.

·Use of standard Modbus communication protocol for TTL232 bus connections,

communication protocol compatibility much better.

·Fully encapsulated PCB, IP67 protection.

·Aluminum housing.

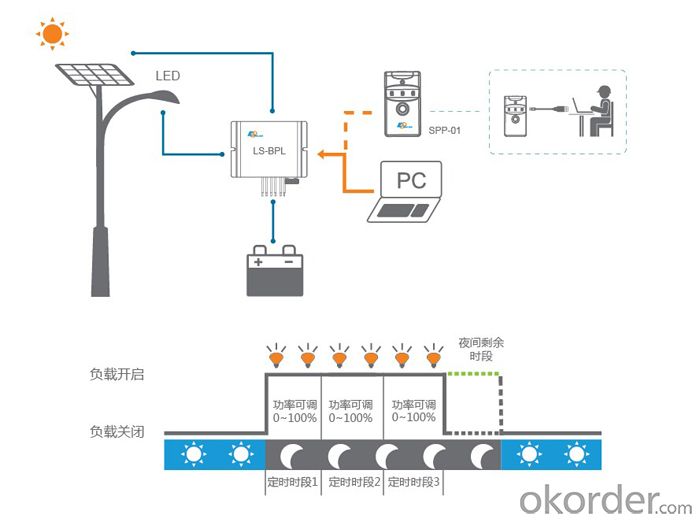

Load control mode:

Manual, Light ON/OFF, Light ON+ Timer, Time Control

Electronic Protections:

·PV array short circuit

·PV reverse polarity

·High voltage transients

·Over discharge

·Overcharge

·Load overload

·Load short circuit

·Battery reverse polarity

·Overheating

Specification:

Electrical parameters | LS102460BPL | LS152480BPL | LS2024100BPL |

Nominal system voltage | 12 / 24VDC | ||

Battery terminal voltage | 8~32V | ||

Maximum PV input voltage | 50V | ||

Rated charge current | 10A | 15A | 20A |

Rated output power | 30W/12V, 60W/24V | 40W/12V, 80W/24V | 50W/12V, 100W/24V |

Rated output current | 2.0A | 2.6A | 3.3A |

Max. efficiency | 95% | ||

Output voltage range | Voltage of battery~60.0V | ||

Load open circle voltage | 60.0V | ||

Power output adjustment time | <10s | ||

Self-consumption | ≤9.1mA(12V); ≤7.0mA(24V) | ||

Control accuracy | < 2% | ||

Temp. compensation coefficient | -3mV/℃/2V(25℃) | ||

Enclosure | IP67 | ||

Dimension | 108.5x73x25.6 mm | 108.5x96x25.6mm | 108.5x110x25.6mm |

Power cable | 4mm2(PV/Batt.) 1.0mm2(Load) | 6mm2(PV/Batt.) 1.5mm2(Load) | 6mm2(PV/Batt.) 1.5mm2(Load) |

Net weight | 0.4kg | 0.5kg | 0.6kg |

Working temperature | -35℃ to +55℃ | ||

Humidity | ≤90%(NC) | ||

FAQ

Q1. What is the difference between MPPT&PWM?

A1. MPPT has higher efficiency, it can track the max power point and won't waste energy.

Q2. What is the efficiency of the MPPT controller?

A2. MPPT>99%, peak conversion efficiency>98%.

Q3. What is the waranty of product?

A3. 12 months.

Q4. What protection does your MPPT controller have?

A4. PV array short circuit, PV reverse polarity, Battery reverse polarity, Over charging, Output short circuit.

- Q: How does a solar controller protect against short circuits?

- A solar controller protects against short circuits by constantly monitoring the current flowing through the system. It is equipped with built-in circuitry that detects any sudden increase in current, which could indicate a short circuit. When a short circuit is detected, the solar controller automatically interrupts the flow of current to prevent any damage to the solar panels or connected devices.

- Q: What is the maximum output current for a solar controller?

- The maximum output current for a solar controller typically depends on the model and specifications of the specific solar controller. It can range from a few amps to several hundred amps, depending on the capacity and design of the controller.

- Q: How does a solar controller handle battery balancing?

- A solar controller handles battery balancing by monitoring the voltage levels of individual batteries connected in a series or parallel configuration. It ensures that each battery in the system is charged and discharged evenly to prevent overcharging or undercharging. This is achieved by automatically adjusting the charging current or diverting excess energy to other batteries until all batteries reach the same state of charge.

- Q: Can a solar controller be used with a solar-powered commercial building?

- Yes, a solar controller can be used with a solar-powered commercial building. A solar controller helps regulate and optimize the charging and discharging of batteries in a solar power system. It ensures that the energy generated by the solar panels is efficiently stored and managed, allowing for reliable and consistent power supply to the building.

- Q: What is the maximum load voltage of a solar controller?

- The maximum load voltage of a solar controller refers to the highest voltage that the controller can handle when supplying power to a load. This voltage limit is crucial to ensure the safe operation of the controller and prevent any damage to the connected load. The maximum load voltage varies depending on the specific model and specifications of the solar controller. It is typically mentioned in the product datasheet or manual provided by the manufacturer. It is important to adhere to this maximum load voltage to prevent overloading the controller, which can lead to overheating, premature failure, or even fire hazards. Therefore, it is recommended to carefully read the specifications of the solar controller and ensure that the load voltage does not exceed the stated maximum limit to ensure optimal and safe performance.

- Q: What is the display type of a solar controller?

- The display type of a solar controller can vary, but commonly it is an LCD (Liquid Crystal Display) screen.

- Q: Is it possible to connect multiple solar controllers together?

- Yes, it is possible to connect multiple solar controllers together. This can be done by connecting the positive and negative terminals of each controller in parallel, allowing them to work together to regulate and manage the charging and discharging of multiple batteries or solar panels.

- Q: What is the role of a solar controller in preventing damage to the solar panels from birds or animals?

- To prevent damage to solar panels from birds or animals, the primary function of a solar controller is to discourage them from landing or nesting on the panels. Various methods are typically employed by solar controllers to achieve this objective. One commonly used technique involves emitting ultrasonic sound waves that are inaudible to humans but unpleasant to birds and animals. These sound waves cultivate an unwelcoming environment around the solar panels, making them less appealing as perching or nesting spots. The solar controller emits these sound waves intermittently, effectively ensuring that the area surrounding the panels remains bird and animal-free. Another approach utilized by solar controllers is the incorporation of visual deterrents, such as reflective surfaces or moving objects. Birds and animals are often frightened off by shiny or reflective surfaces, as they perceive them as potential predators or threats. Integrating these visual deterrents into the design of the solar controller aids in discouraging birds and animals from approaching the panels. Furthermore, solar controllers may also employ physical barriers or netting to obstruct access to the panels. This strategy prevents birds or animals from directly landing on the panels or causing damage with their claws or beaks. These physical barriers are specifically designed to be lightweight and durable, ensuring that they do not impede the performance of the solar panels while effectively safeguarding them against potential harm. To summarize, the primary role of a solar controller in preventing damage to solar panels from birds or animals is to create an environment that is unappealing and inhospitable to these creatures. By employing deterrent mechanisms such as ultrasonic sound waves, visual deterrents, and physical barriers, solar controllers contribute to the preservation and functionality of the solar panels by keeping birds and animals at a distance.

- Q: Can a solar controller be used with a battery bank of different capacities?

- Yes, a solar controller can be used with a battery bank of different capacities. The solar controller's main function is to regulate the flow of current from the solar panels to the batteries, ensuring that they are charged efficiently and preventing overcharging. It can work with battery banks of varying capacities by adjusting the charging parameters accordingly. However, it's important to note that using batteries of different capacities may result in uneven charging and discharging rates, potentially affecting the overall performance and lifespan of the battery bank.

- Q: How does a solar controller prevent overvoltage damage to the batteries?

- A solar controller, also known as a charge controller, prevents overvoltage damage to the batteries by regulating the charging process and ensuring that the batteries are not overcharged. When solar panels generate electricity, they convert sunlight into electrical energy, which is then used to charge the batteries. Without a solar controller, the charging process can be unregulated, leading to overcharging and potentially damaging the batteries. The solar controller acts as a middleman between the solar panels and the batteries. It monitors the voltage and current being produced by the solar panels and adjusts the charging parameters accordingly. One of the key functions of a solar controller is to maintain the battery voltage at an optimal level. It does this by using a technique known as pulse width modulation (PWM) or maximum power point tracking (MPPT). These techniques dynamically adjust the current flow from the solar panels to the batteries, preventing overvoltage situations. Additionally, solar controllers often include features like built-in voltage and temperature sensors. These sensors constantly monitor the battery voltage and temperature, allowing the controller to take appropriate actions to prevent overcharging. When the solar controller detects that the battery is fully charged or nearing its maximum capacity, it reduces or interrupts the charging current flowing from the solar panels. This prevents the batteries from being overcharged and ensures their longevity. Overall, the solar controller plays a crucial role in protecting the batteries from overvoltage damage by regulating the charging process, monitoring the battery voltage and temperature, and adjusting the charging parameters accordingly.

Send your message to us

PWM Solar Charge Controller and LED Constant Current Driver 20A,12/24V, LS2024100BPL

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords