PVC Foam Board PVC Foam Sheets PVC Foam Panel Manufacturer Exporter

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

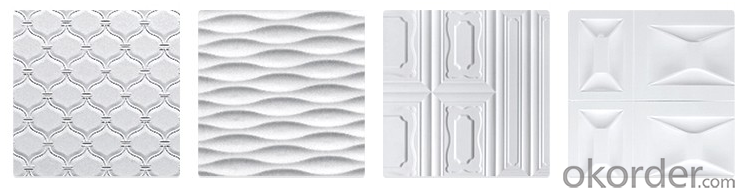

There are 2 kinds of PVC foam board, one is Common PVC foam board with white surface, the other is called Exclusive PVC foam board with colorful surface.

The PVC foam board is made through foaming and pressing into shape with additive. It is widely used in Sanitaryware, Construction material and Advertising material.

PVC foam board has its characteristics of easily sawed, bonded, nailed, joint and hot moulding.

We are specialized in manufacturing PVC foam board.

Standard Size We Provide

-1220*2440mm,Thickness:1mm-25mm

-1560*3050mm,Thickness:1mm-20mm

-2050*3050mm,Thickness:1mm-18mm

Features:

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated.

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough,rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti-deformed

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection

4. Sanitarywares, kitchen cabinet, washroom cabinet.

Good performance:

1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

7, nail, wrest and rivet

Please tell me the following information and I'll send you the quotation without delay:

1.Color(white,black,grey,red,blue or other)

2.Thickness(1.0mm-33mm)

3.Size(Customized is available)

4.Density(0.35-0.90/m3)

5.Quantity(affecting the delivery time)

- Q: something i had as a kidit consist of a piece of cardboard, black pad with a plastic sheet over it, that you draw on with a plastic pen and it will leave black lines from the plastic being pressed to the black pad, and when you were done you peel the plastic sheet from the black part and the drawing would be cleared.sorry i;m bad at explaining but what is it called??? how can i find it again

- Oh my gosh! I used to LOVE those things! Next best thing to etch a sketch! :) unfourtunatly i dont remember the names of them... But you got me curious so im keepin an eye out for the answers to this one... Ill be back! Lol

- Q: Sharp has plasmacluster technology (+ - ion) honey comb dedorizer to kill germs,mouls get rid of bad fishy smell.Mitsubishi has vitamins making factory to keep veg fresh so asToshiba has hybrid Plasma dedorizer doing the same function.Then there is Hitachi w. nano titanium technology.Yet Samsung also has nanotechnology.Too many to choose from.By the way 3 door fridge is better than a 2 door fridge ?

- wal*marts

- Q: Are plastic sheets resistant to bending under heavy loads?

- Yes, plastic sheets are generally resistant to bending under heavy loads due to their inherent flexibility and strength. However, the degree of resistance may vary depending on the specific type and thickness of the plastic sheet used.

- Q: Can plastic sheets be used for room dividers?

- Yes, plastic sheets can be used for room dividers. They are lightweight, versatile, and easy to install. Plastic sheets can provide privacy, separate spaces, and even act as sound barriers.

- Q: Are plastic sheets resistant to tearing or puncturing?

- Yes, plastic sheets are generally resistant to tearing and puncturing due to their durability and flexibility.

- Q: i am working on an art project and I am wondering if there is a crafty type way for me to transfer the typed text from one sheet of paper to another (like to lift the ink off the paper somehow). I am not concerned about the words being recognizable or readable, I just like the aesthetic of words that don't necessarily mean anything mixed with pictures. thanks!

- It's called a photocopier. Photocopy the page onto a sheet of transparent plastic. Then lay the plastic over the new sheet where you want the letters to appear. If you don't want the plastic, the process is trickier. It still can be done. Photocopy the page onto plastic as before. Then lay the photocopied plastic sheet reversed on the photocopying glass. Copy onto a piece of paper. The result will be a sheet of paper with the letters reversed. Since photocopiers use toner that is baked onto the page, you need to take the sheet with reverse lettering and iron (using a hot iron) the reversed lettering onto the page you want it to appear. Since you are reversing a reversal, the result will be correct left-to-right. It might take several tries to get the technique down right, but it is do-able. Whether it is worth it, you'll have to determine.

- Q: Can I use all these plastics sheets and duct tape I bought after 9/11 to protec me from e. bola?

- ebola ? what about the marberg , lassa , dengue , lyme , babesiosis , west nile like virus , norovirus , typhoid , mumps , measeles, tularemia , hanta , brucelosis , chicken pox , etc , etc ?

- Q: Can plastic sheets be used for DIY drawer organizers?

- Yes, plastic sheets can be used for DIY drawer organizers. They are versatile and can be easily cut and shaped to fit the dimensions of your drawer. Plastic sheets are durable and can help keep items in your drawer organized and separated.

- Q: Are plastic sheets fire-resistant?

- No, plastic sheets are not fire-resistant.

- Q: How can the circuit board effectively prevent static interference?

- Inspection Notes? do not use a multimeter to detect electrostatic discharge sensitive devices, lead terminals, or corresponding wires. If you need to guard such detection; in the detection, should be in direct contact with the ground test pen on the electrostatic.From the requirements of ESD protection, when the circuit boards such as MOS devices are pulled out or inserted, the following operations shall not be allowed in the case of power on.The device for detecting circuit boards must be reliably grounded.

Send your message to us

PVC Foam Board PVC Foam Sheets PVC Foam Panel Manufacturer Exporter

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords