PVC Electrical Tape with Rubber Based Adhesive - Packaging Tape Ireland

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of PVC Electrical Tape With Rubber Based Adhesive

A thin premium grade plasticized PVC film coated with an aggressive rubber based adhesive with good characteristics. It is highly conformable and unaffected by most chemicals and moisture

Application of PVC Electrical Tape With Rubber Based Adhesive

Electric insulation below 600V; Insulating wrapping of electric wires and cables; Marking of electric wires and cables; Can be used indoors and out door

Available Size of PVC Electrical Tape With Rubber Based Adhesive

Paper Core ID: 76mm; 56mm; 38mm; 32mm

Jumbo Roll size: 1250mm x 33m

Cut roll size: 19mm x 10m; 19mm x 20m or as per customer's requirement

Cut rolls: Nine rolls in one plastic bag, placed in cartons, with or without pallet

Packing of PVC Electrical Tape With Rubber Based Adhesive

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

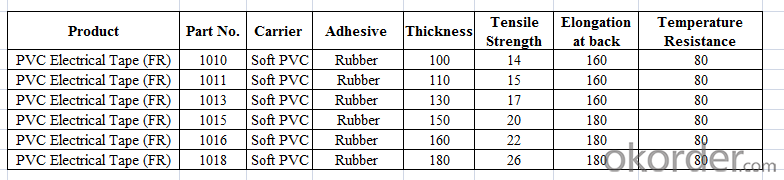

Technical Data of PVC Electrical Tape With Rubber Based Adhesive

Product Show of PVC Electrical Tape With Rubber Based Adhesive

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

- Q: What is the difference between acrylic and hot melt adhesive for packaging tape?

- Acrylic and hot melt adhesives are two common types of adhesives used for packaging tape, and they have some key differences. One major difference is the bonding strength. Hot melt adhesive is known for its excellent bonding strength, making it suitable for heavy-duty applications. It creates a strong and durable bond that can withstand rough handling and varying temperatures. On the other hand, acrylic adhesive typically offers a lower bonding strength compared to hot melt adhesive. While it is still suitable for most general packaging needs, it may not be as ideal for heavy or bulky items. Another difference lies in the application process. Hot melt adhesive is applied in a molten state and solidifies upon cooling. It is typically dispensed using a hot melt glue gun or a hot melt applicator. The quick setting time of hot melt adhesive allows for fast packaging operations, making it popular in high-volume settings. In contrast, acrylic adhesive is applied in a liquid form and requires some time to cure and form a strong bond. It can be applied using a hand dispenser or a tape gun, and it usually requires some pressure for optimal adhesion. Additionally, hot melt adhesive offers good adhesion to a wide range of surfaces, including cardboard, plastics, and metals. It is highly versatile and can be used for various packaging materials. Acrylic adhesive also adheres well to different surfaces, but it may not have the same level of compatibility with certain low-energy surfaces, such as polyethylene or polypropylene. Furthermore, temperature resistance is another factor to consider. Hot melt adhesive performs well in both high and low temperatures, maintaining its bonding strength. It can withstand freezing temperatures and heat without compromising its adhesive properties. Acrylic adhesive, while generally offering good temperature resistance, may not be as effective in extreme conditions, particularly at very high or low temperatures. In summary, the main differences between acrylic and hot melt adhesives for packaging tape lie in bonding strength, application process, surface compatibility, and temperature resistance. While hot melt adhesive provides superior bonding strength, fast setting time, and excellent temperature resistance, acrylic adhesive offers versatility, ease of application, and good adhesion to most surfaces. The choice between the two depends on the specific packaging needs, materials, and environmental conditions.

- Q: Can packaging tape be used for sealing plastic tubing?

- Packaging tape has the capability to seal plastic tubing. Its design ensures a robust and reliable seal on different surfaces, including plastic materials. Nonetheless, it is crucial to take into account the particular purpose and demands of the plastic tubing. In instances where the tubing is intended for containing pressurized liquids or gases, or if it necessitates a long-lasting and resilient seal, specialized techniques like heat sealing or specific adhesives formulated for plastic materials might be more suitable. Ultimately, the appropriateness of packaging tape for sealing plastic tubing relies on the specific situation and requirements of the application.

- Q: What are the advantages of using packaging tape over other sealing methods?

- One advantage of using packaging tape over other sealing methods is its versatility. Packaging tape can be used to seal a wide variety of materials, such as cardboard boxes, plastic bags, and envelopes. It provides a strong and secure seal that can withstand the rigors of shipping and handling. Additionally, packaging tape is easy to use, requiring minimal effort and time for application. It is also cost-effective, as a small amount of tape can go a long way in sealing multiple packages. Lastly, packaging tape is often available in different sizes, colors, and strengths, allowing for customization and meeting specific packaging needs.

- Q: Can packaging tape be used for sealing plastic flower pots?

- Yes, packaging tape can be used for sealing plastic flower pots. Packaging tape is a versatile adhesive tape that is commonly used for sealing boxes and packages. Its strong adhesive properties make it suitable for securing plastic flower pots and preventing any leaks or spills. However, it is important to ensure that the surface of the plastic flower pot is clean and dry before applying the tape, as any dirt or moisture may affect its adhesion. Additionally, it is worth noting that there are specific tapes designed for sealing or repairing plastic materials, which may offer better performance and durability when used on plastic flower pots.

- Q: What are the benefits of using tear-resistant packaging tape?

- The benefits of using tear-resistant packaging tape include increased durability and protection for packages during transit, reduced risk of damage or tampering, and improved overall package security.

- Q: How do I prevent packaging tape from getting tangled?

- To prevent packaging tape from getting tangled, ensure that the tape roll is placed on a dispenser or a stationary surface with the sticky side facing down. Additionally, avoid pulling the tape too quickly or at an angle, as this can cause it to twist and tangle. Taking these precautions will help maintain the tape's smooth flow and prevent any frustrating tangles.

- Q: Can packaging tape be used for sealing wooden crates?

- Yes, packaging tape can be used for sealing wooden crates. It provides a strong and secure seal to keep the contents of the crate safe during transportation or storage.

- Q: How does packaging tape perform in dusty environments?

- Packaging tape typically functions effectively in dusty environments; however, its performance may vary based on the specific conditions and tape quality. The presence of dust particles has the potential to hinder tape adhesion, resulting in reduced stickiness and package security. Nevertheless, most packaging tapes are designed to resist dust and other contaminants, equipped with a robust adhesive backing capable of withstanding moderate levels of dust. To optimize tape performance in dusty environments, it is advisable to select tapes with higher tack or adhesive strength. These tapes are specifically engineered to provide superior adhesion and stickiness, even in dusty conditions. Additionally, choosing tapes with a thicker backing material can prevent dust particles from penetrating the tape and compromising its adhesive properties. It is crucial to note that excessive dust accumulation can still impact the tape's performance, particularly when fine and abundant. In such cases, it is recommended to regularly clean the package surfaces before applying the tape to ensure optimal adhesion. Adequate surface preparation, such as wiping the area with a clean cloth or using compressed air to remove dust, can enhance tape performance in dusty environments. In conclusion, while packaging tape generally performs well in dusty environments, it is important to consider tape quality, dust exposure level, and proper surface preparation to ensure optimal adhesion and package security.

- Q: I saw a lot of different sizes of sealing tape on the Internet. Some are very thick and some are thin. Will the thickness of the same number be the same in the same number of yards? Some 100Y have around 1.5cm of the flesh, but some 100Y only about 0.7cm of the flesh, what is this possible? Or is it true or false? Ask the personage inside course of study to help solve!

- I saw a lot of different sizes of sealing tape on the Internet. Some are very thick and some are thin. Will the thickness of the same number be the same in the same number of yards? Some 100Y have around 1.5cm of the flesh, but some 100Y only about 0.7cm of the flesh, what is this possible? Or is it true or false? Ask the personage inside course of study to help solve!

- Q: Can packaging tape be used for sealing packages for shipping?

- Yes, packaging tape is specifically designed for sealing packages during shipping. It provides a strong and secure seal to prevent any damage or tampering to the contents of the package.

Send your message to us

PVC Electrical Tape with Rubber Based Adhesive - Packaging Tape Ireland

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords