Amazon Prime Packaging Tape - PVC Electrical Tape with Flame Retardance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of PVC Electrical Tape With Flame Retardance

A thin premium grade plasticized PVC film coated with an aggressive rubber based adhesive with good characteristics. It is highly conformable and unaffected by most chemicals and moisture

Application of PVC Electrical Tape With Flame Retardance

Electric insulation below 600V; Insulating wrapping of electric wires and cables; Marking of electric wires and cables; Can be used indoors and out door

Available Size of PVC Electrical Tape With Flame Retardance

Paper Core ID: 76mm; 56mm; 38mm; 32mm

Jumbo Roll size: 1250mm x 33m

Cut roll size: 19mm x 10m; 19mm x 20m or as per customer's requirement

Cut rolls: Nine rolls in one plastic bag, placed in cartons, with or without pallet

Packing of PVC Electrical Tape With Flame Retardance

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

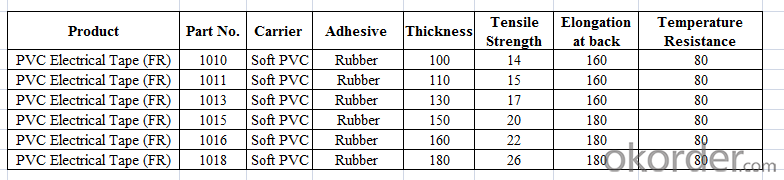

Technical Data of PVC Electrical Tape With Flame Retardance

Product Show of PVC Electrical Tape With Flame Retardance

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

- Q: Can packaging tape be used for sealing protective packaging materials like bubble wrap?

- Yes, packaging tape can be used for sealing protective packaging materials like bubble wrap. Packaging tape is designed to provide a strong and secure seal on various types of materials, including bubble wrap. It is commonly used in packaging and shipping industries to ensure that the contents of a package are well-protected and secure during transit. When using packaging tape to seal bubble wrap, it is important to apply the tape along the edges of the bubble wrap to create a tight seal and prevent any potential damage or exposure.

- Q: Can packaging tape be used for heavy-duty packaging?

- Yes, packaging tape can be used for heavy-duty packaging. It is designed to provide strong adhesion and durability, making it suitable for securing and sealing heavy or bulky items during transportation or storage.

- Q: Does packaging tape come in different lengths for convenience?

- Yes, packaging tape does come in different lengths for convenience.

- Q: Is packaging tape safe to use on ceramic tiles?

- Yes, packaging tape is generally safe to use on ceramic tiles. Packaging tape is designed to adhere to a variety of surfaces, including ceramic tiles. However, it is important to ensure that the tape is removed carefully to avoid damaging the tile or leaving any residue behind. It is recommended to test a small inconspicuous area first to ensure that the tape does not cause any damage or discoloration. Additionally, it is always a good idea to follow the manufacturer's instructions and guidelines for using packaging tape on specific surfaces.

- Q: How do I remove packaging tape residue?

- To remove packaging tape residue, you can start by applying a small amount of oil or rubbing alcohol to a cloth or sponge and gently rubbing the affected area. This should help loosen the adhesive. Alternatively, you can also try using a mixture of warm water and dish soap, or a commercial adhesive remover. Make sure to test any method on a small, inconspicuous area first to ensure it doesn't damage the surface.

- Q: Is packaging tape resistant to oil or grease?

- Packaging tape is known for its general resistance to oil and grease. Its main purpose is to securely seal boxes and packages, offering protection to the contents during transportation. Usually, these tapes are manufactured using materials like polypropylene or PVC, which possess properties that make them resistant to different substances, including oil and grease. This resistance plays a significant role in preventing the tape from deteriorating or losing its adhesion when exposed to oils or greases commonly found in industrial or commercial environments. Nevertheless, it should be noted that the level of resistance may differ depending on the type and quality of the packaging tape employed.

- Q: Does packaging tape come in different lengths?

- Yes, packaging tape does come in different lengths. Packaging tape is available in various lengths to accommodate different packaging needs. Common lengths for packaging tape include 55 yards, 110 yards, and 1000 yards, although other lengths may be available as well. The length of the packaging tape you choose depends on the size and quantity of packages you plan to seal. It is important to consider the length of packaging tape needed to ensure you have enough to securely seal your packages without running out.

- Q: How does packaging tape perform in high-temperature conditions?

- Packaging tape typically performs well in high-temperature conditions as it is designed to withstand heat. The adhesive used in packaging tape is usually heat-resistant, ensuring that the tape remains securely bonded even at elevated temperatures. However, it is important to note that the performance may vary depending on the specific type and quality of packaging tape used.

- Q: What are the considerations for using packaging tape on plastic packaging materials?

- When working with plastic packaging materials and using packaging tape, it is essential to keep several important factors in mind. These factors include: 1. Adhesive Compatibility: Ensuring that the adhesive used in the packaging tape is compatible with the specific type of plastic material is crucial. Different plastics have different surface properties, and they may require different adhesive formulations to ensure proper bonding. For instance, low surface energy plastics like polyethylene may necessitate a tape with a specially designed adhesive for such surfaces. 2. Strength and Durability: Plastic packaging materials come in varying thicknesses and strengths. When choosing packaging tape, it is important to consider the strength and durability required for the specific plastic material being used. The tape should be strong enough to securely hold the packaging together without tearing or breaking, thus maintaining the package's integrity during handling and transportation. 3. Temperature Resistance: Plastic packaging materials can be sensitive to temperature changes. If the package is exposed to extreme temperatures, such as heat or cold, the packaging tape should be capable of withstanding these conditions without losing its adhesive properties. Certain plastic materials may also shrink or expand due to temperature changes, which can impact the tape's adhesion. Therefore, it is important to select a tape suitable for the expected temperature range. 4. Residue and Damage: Some packaging tapes may leave behind adhesive residue or cause damage when removed from plastic packaging materials. This can pose a problem if the packaging needs to be reused or if the plastic material is susceptible to damage. By choosing a packaging tape that is designed to be easily removable or leaves minimal residue, these concerns can be mitigated. 5. Regulatory Compliance: Depending on the industry or product being packaged, there may be specific regulations and standards that must be followed. It is important to ensure that the packaging tape used complies with any applicable regulations, such as food safety standards or environmental requirements. By taking these factors into consideration, one can select the appropriate packaging tape that will effectively adhere to plastic packaging materials while also providing the necessary strength, durability, temperature resistance, and compliance with regulations.

- Q: How does packaging tape perform on porous surfaces?

- Packaging tape generally does not perform well on porous surfaces. Porous surfaces such as cardboard, paper, or fabric tend to absorb the adhesive on the tape, resulting in a weak bond and reduced effectiveness. It is recommended to use alternative methods or specialized tapes specifically designed for porous surfaces to achieve better adhesion and secure packaging.

Send your message to us

Amazon Prime Packaging Tape - PVC Electrical Tape with Flame Retardance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords