Gorilla Packaging Tape for PVC Electrical Tape for Electric Wires and Cables

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of PVC Electrical Tape for Electric Wires and Cables

A thin premium grade plasticized PVC film coated with an aggressive rubber based adhesive with good characteristics. It is highly conformable and unaffected by most chemicals and moisture

Application of PVC Electrical Tape for Electric Wires and Cables

Electric insulation below 600V; Insulating wrapping of electric wires and cables; Marking of electric wires and cables; Can be used indoors and out door

Available Size of PVC Electrical Tape for Electric Wires and Cables

Paper Core ID: 76mm; 56mm; 38mm; 32mm

Jumbo Roll size: 1250mm x 33m

Cut roll size: 19mm x 10m; 19mm x 20m or as per customer's requirement

Cut rolls: Nine rolls in one plastic bag, placed in cartons, with or without pallet

Packing of PVC Electrical Tape for Electric Wires and Cables

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

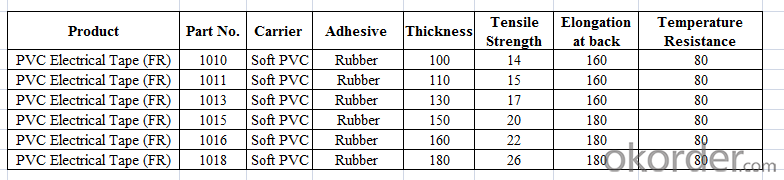

Technical Data of PVC Electrical Tape for Electric Wires and Cables

Product Show of PVC Electrical Tape for Electric Wires and Cables

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

- Q: Is packaging tape heat resistant?

- Indeed, packaging tape typically exhibits heat resistance. The composition of most packaging tapes involves materials like polypropylene or acrylic, which possess elevated melting points and can endure extreme temperatures. Thanks to this heat resistance, packaging tape serves diverse purposes, such as sealing boxes and packages that may encounter heat during transportation or storage. Nevertheless, it is crucial to acknowledge that the heat resistance of packaging tape may fluctuate based on the tape's brand and quality. Hence, it is advisable to review the product specifications or seek guidance from the manufacturer to guarantee the tape's appropriateness for the desired utilization and temperature circumstances.

- Q: What are the benefits of using pre-printed packaging tape with warning messages?

- Using pre-printed packaging tape with warning messages has several benefits. Firstly, it helps to ensure the safety of the package contents and the individuals handling them. The warning messages act as a visual reminder of any potential hazards or special handling instructions, reducing the risk of accidents or mishandling. Secondly, it saves time and effort by eliminating the need for separate warning labels or writing instructions on the packaging. The pre-printed tape provides a clear and professional warning message that can be easily recognized by anyone involved in the packaging process. Lastly, it enhances the overall professionalism and branding of the company. The customized warning messages on the tape can include the company's logo, contact information, or any other branding elements, making the package stand out and leaving a positive impression on the recipient.

- Q: Can packaging tape be used for sealing packages with high-value contents?

- Yes, packaging tape can be used for sealing packages with high-value contents. However, it is important to ensure that the tape used is strong, durable, and tamper-evident to provide adequate security and protection for the valuable contents.

- Q: Can packaging tape be used on all types of surfaces?

- No, packaging tape may not adhere well to all types of surfaces. It is most effective on smooth and clean surfaces, such as cardboard or paper, but may not stick properly to rough or textured surfaces.

- Q: Can packaging tape be used for sealing containers with liquids?

- Yes, packaging tape can be used for sealing containers with liquids. However, it is important to note that not all packaging tapes are designed to withstand contact with liquids for extended periods of time. If you are sealing containers with liquids, it is recommended to use packaging tape that is specifically designed for this purpose, such as water-resistant or waterproof tape. These tapes are generally more durable and have enhanced adhesive properties to ensure a secure seal and prevent leakage. Additionally, it is advisable to properly clean and dry the surface of the container before applying the tape to ensure optimal adhesion.

- Q: Can packaging tape be used for sealing packages with sharp or pointed objects?

- Yes, packaging tape can be used for sealing packages with sharp or pointed objects. However, it is recommended to take additional precautions such as cushioning the sharp or pointed objects with protective material or placing them in a sturdy box to prevent the tape from getting damaged or punctured during transit.

- Q: Can packaging tape be used for securing shipments during transit?

- Yes, packaging tape is commonly used for securing shipments during transit. It provides a strong and reliable seal that helps keep packages intact, preventing them from opening or getting damaged during transportation.

- Q: Is packaging tape resistant to chemicals?

- Packaging tape typically exhibits resistance against a broad array of chemicals. Commonly, packaging tapes are crafted from materials like polypropylene or polyvinyl chloride (PVC), renowned for their chemical-resistant properties. These materials possess the capacity to endure exposure to different chemicals, including solvents, acids, and bases. Nevertheless, it is crucial to acknowledge that the degree of chemical resistance can vary depending on the specific type and quality of the packaging tape utilized. Certain tapes may display higher chemical resistance compared to others. Furthermore, the tape's resistance can be influenced by the duration and intensity of chemical exposure. To guarantee the tape's chemical resistance, it is advisable to review the manufacturer's specifications and guidelines concerning chemical compatibility. If you are handling exceedingly harsh chemicals or engaging in specialized applications, it may be necessary to seek out packaging tapes explicitly designed for those specific conditions.

- Q: What are the common brands of packaging tape?

- Scotch, Duck, 3M, Gorilla, and Uline are among the commonly known brands of packaging tape. These brands have gained recognition for their resilient nature, strong adhesion, and user-friendly characteristics. They offer a diverse range of choices, including clear, tan, and colored tapes, as well as various widths and lengths to cater to different packaging requirements. Furthermore, these brands frequently offer alternatives for different packaging materials such as cardboard boxes, plastic bags, and bubble wrap. It is crucial to opt for a reputable brand while selecting packaging tape to guarantee the dependable and secure sealing of packages.

- Q: Can packaging tape be used for sealing wooden crates or pallets?

- Yes, packaging tape can be used for sealing wooden crates or pallets. It provides a secure adhesion and helps to keep the contents of the crates or pallets protected during transportation or storage.

Send your message to us

Gorilla Packaging Tape for PVC Electrical Tape for Electric Wires and Cables

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches