PVC Electrical Insulation Tape High Quality Heat Resistant Waterproof - Packaging Tape Tesco

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Tape

PVC tapes are made of soft pvc film coated with rubber pressure-sentitive adhesive.

Application of PVC Tape

PVC tapes are widely used in auto harness, wrapping of wire, and insulation protection. It is the main insulation material of automobilehousehold electrical apparatus.

Advantage of PVC Tape

Corrosion protection for metal piping systems above and below ground.

Corrosion protection for fittings and joints on mill coated pipe.

Corrosion protection of electrical conduit & fittings.

Resists corrosive action by salt water, soil acids, alkalies and salts.

Prevents dielectric corrosion between buried steel pipe and soil minerals.

Pictures of PVC Tape

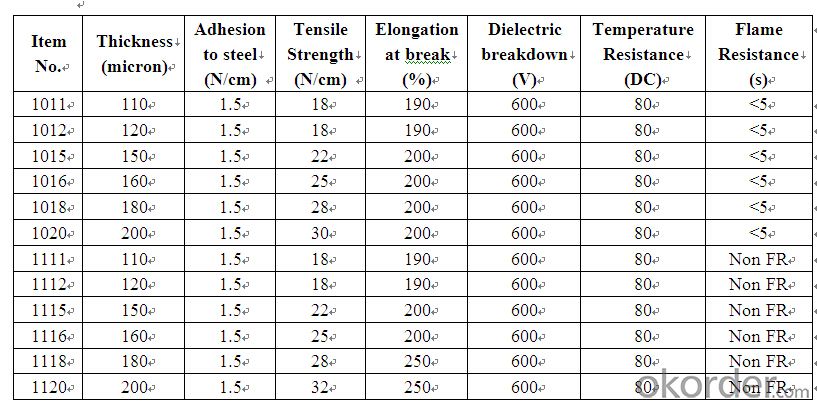

Specification of PVC Tape

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

- Q: What are the benefits of using UV-resistant packaging tape?

- UV-resistant packaging tape offers numerous advantages. Firstly, it is specifically designed to endure prolonged exposure to sunlight, preventing it from deteriorating or degrading. This is particularly crucial when shipping or storing items outdoors or in areas with direct sunlight. With UV-resistant tape, packages can remain securely sealed for extended periods as it maintains its adhesive properties and structural integrity. Furthermore, UV-resistant packaging tape safeguards the contents of packages from UV ray damage. Sunlight can cause materials like paper, fabrics, or plastics to fade, discolor, or degrade. By utilizing UV-resistant tape, these items are shielded from the harmful effects of UV rays, preserving their quality and appearance. Moreover, UV-resistant packaging tape boasts long-lasting adhesion. Unlike regular tape, which may lose its stickiness over time when exposed to sunlight, UV-resistant tape is specially formulated to bond tightly and securely to various surfaces. This reliable adhesion minimizes the risk of packages opening or items sustaining damage during transit. Additionally, UV-resistant packaging tape provides peace of mind for both senders and recipients. By opting for tape that is resistant to UV rays, businesses and individuals can ensure that their packages arrive in the same condition they were sent, enhancing their professional image and customer satisfaction. This advantage is particularly vital when shipping valuable or delicate items that require extra protection. In conclusion, UV-resistant packaging tape offers enhanced durability, protection against UV damage, long-lasting adhesion, and increased confidence in package integrity. By selecting UV-resistant tape, individuals and businesses can effectively safeguard their packages and their contents, even when exposed to prolonged sunlight.

- Q: Can packaging tape be used for heavy-duty packaging?

- Indeed, heavy-duty packaging can utilize packaging tape. Assorted varieties of packaging tapes can be found in the market, some of which are specifically engineered to withstand the challenges posed by heavy or bulky packages. Typically, these tapes are crafted using resilient materials such as reinforced fibers or potent adhesives, offering exceptional strength and ensuring secure packaging. They possess the capability to securely bind rigid and weighty boxes, preventing any unravelling or tearing during transportation. When selecting packaging tape for heavy-duty packaging, it is vital to take into account both the weight and dimensions of the package, as well as the unique requirements of the shipping or handling process.

- Q: Can packaging tape be used for sealing plastic garment bags?

- Yes, packaging tape can be used for sealing plastic garment bags. Packaging tape is designed to provide a secure and durable seal on various materials, including plastic. It can help keep the plastic garment bag tightly sealed, preventing dust, moisture, and other contaminants from entering the bag and potentially damaging or dirtying the garments inside. Additionally, packaging tape is typically easy to use, as it can be easily cut with a dispenser or a pair of scissors, making it convenient for sealing plastic garment bags.

- Q: Can packaging tape be used for sealing paper bags?

- Yes, packaging tape can be used for sealing paper bags.

- Q: Is packaging tape easy to cut with scissors?

- Packaging tape is typically effortless to cut using scissors. It is specifically crafted to be easily cut with ordinary household scissors, offering convenience for different packaging requirements. The tape's thickness and adhesive qualities work together harmoniously, enabling neat and accurate cuts, guaranteeing that the tape can be effortlessly handled and detached as needed.

- Q: Can packaging tape be used for sealing chemical or hazardous material containers?

- Packaging tape is not recommended for sealing chemical or hazardous material containers. This is because packaging tape typically does not have the necessary properties to effectively contain and prevent leakage of these substances. Chemical or hazardous materials often require specialized containers and sealing methods to ensure safety and compliance with regulations. These containers are designed to withstand the corrosive or reactive nature of the substances they hold, and their seals are engineered to provide a secure and leak-proof closure. Using packaging tape to seal chemical or hazardous material containers can pose risks such as leakage, contamination, and exposure to harmful substances. It may not provide a reliable barrier against leaks or spills, which could result in accidents, injuries, or environmental damage. To properly seal chemical or hazardous material containers, it is recommended to use specific sealing materials that are designed for these purposes. This may include specialized caps, gaskets, or seals that are compatible with the particular substance being contained. Additionally, it is crucial to follow the guidelines and regulations provided by relevant authorities for the safe handling, storage, and transportation of these materials.

- Q: Does packaging tape have an expiration date?

- Packaging tape typically does not have an expiration date. This is because packaging tape is usually made from durable materials such as polypropylene or PVC, which have a long shelf life and do not degrade easily over time. As long as the tape is stored in a cool, dry place, away from direct sunlight and extreme temperatures, it should remain effective for a long period. However, it is important to note that the adhesive on packaging tape may lose its stickiness over time, especially if it is exposed to heat or moisture. So, while packaging tape may not have an official expiration date, it is advisable to use it within a reasonable timeframe to ensure its adhesive properties are still intact.

- Q: Can packaging tape be used for sealing household or kitchen items?

- Yes, packaging tape can be used for sealing household or kitchen items. It provides a strong and secure seal, making it suitable for sealing boxes, containers, and various kitchen items like food storage bags or jars. However, it is important to ensure that the tape is food safe and does not come into direct contact with consumable items.

- Q: Does packaging tape have a specific weight capacity?

- Packaging tape indeed possesses a specific weight capacity. The weight capacity of packaging tape relies on its thickness, width, and overall quality. Typically, packaging tapes are engineered to effectively seal boxes and packages, with their weight capacity determined by their adhesive strength and resilience. The majority of standard packaging tapes can handle a weight capacity ranging from approximately 20 to 30 pounds. Nonetheless, there are heavy-duty packaging tapes available that can manage weights of 50 pounds or more. It is crucial to take into account the weight of the package or box that requires sealing and opt for a packaging tape that can accommodate the precise weight capacity in order to ensure a secure and dependable seal.

- Q: Is packaging tape safe to use on stainless steel?

- Yes, packaging tape is safe to use on stainless steel. Packaging tape is typically made from materials that are not corrosive and will not damage the surface of stainless steel. However, it is always a good idea to test the tape on a small, inconspicuous area of the stainless steel before applying it to the entire surface, especially if the tape will be left on for an extended period of time. Additionally, removing the tape gently and slowly can help prevent any potential damage or residue on the stainless steel.

Send your message to us

PVC Electrical Insulation Tape High Quality Heat Resistant Waterproof - Packaging Tape Tesco

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords