Printed Tinplate, Imported Printing Machine, JIS G3303

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Usage

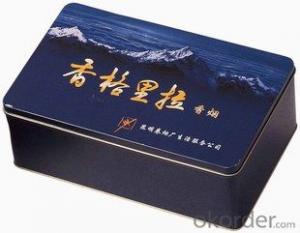

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Quality

As a state owned company and a large tinplate supplier in China, our tinplate quality ranks 1st level in China, similar to Bao Steel, Posco etc.

3. Specification

standard: GB/T2520, JIS G3303, DIN EN10202

Material: MR /SPCC

Thickness available: 0.16-0.50MM

Width available: 600~1050MM

Temper grade: T1 – DR8

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g and others

Package: sea worthy export package.

Applications: Tin can for chemicals & paint cans, industrial cans, food cans

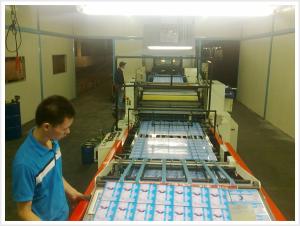

4. Our factory photo & equipments

5. Our Markets:

now our tinplate has been sold to more than 50 countries, including Europe country, Gulf Area, South American, South Afric etc.

6. Our Overseas Wareouses:

Furthermore, in the year 2014, we have more than 10 overseas warehouses all over the word, located in KSA, UAE, Oman, Russia, Kuwait, Qatar, Oman, Chile, Brazil etc.

7. FAQ

a. what's the annual output?

about 500,000 tons per year.

b. where's the raw matrial from?

our hot rolled coil is purchased from Capital Steel and other state owned mill, with quite good quality.

c. how long is the delivery time?

normally for SPCC about 45~55 days, while 65~75 days for MR material

d. how to control the quality during production process?

inside our workshop, we have MES syestem. It realizes the optimization of the production procedure in the workshop. It could record each step of the whole production procedures, and if some problem appears, factory could easily found and take action, it’s quite helpful to monitor and control the quality.

- Q: What are the common uses of tinplate?

- Tinplate is commonly used in the packaging industry for making cans, containers, and lids for food and beverages. It is also used in the production of aerosol cans, paint cans, and metal closures. Additionally, tinplate is used for making various household items such as kitchen utensils, storage boxes, and tin toys.

- Q: How is tinplate coated with metallic coatings?

- Tinplate is coated with metallic coatings through a process known as electroplating, where a thin layer of metal is deposited onto the surface of the tinplate using an electric current. This electroplating process helps to enhance the corrosion resistance and aesthetic appeal of the tinplate.

- Q: How does tinplate contribute to the reduction of carbon emissions?

- Tinplate contributes to the reduction of carbon emissions through its sustainable production process and recyclability. Compared to other packaging materials, tinplate has a low carbon footprint as it requires less energy and releases fewer greenhouse gases during manufacturing. Additionally, tinplate is a highly recyclable material, allowing for the efficient reuse of resources and reducing the need for new production. By promoting the use of tinplate, we can minimize carbon emissions and work towards a more environmentally friendly packaging solution.

- Q: Tinplate which applies to product packaging?

- Barrier: tinplate cans have excellent barrier properties than any other materials are excellent, gas barrier properties, moisture resistance, shading and aroma were good, and the sealing is reliable, reliable protection products. 3. mature technology and high production efficiency: the production of tinplate has a long history, mature technology is a set of production equipment with matching, high production efficiency, can meet a variety of product packaging needs.

- Q: What are the different methods of reusing tinplate packaging?

- There are several methods of reusing tinplate packaging including repurposing them for storage purposes, using them as planters for indoor or outdoor plants, incorporating them into DIY craft projects, or donating them to charitable organizations that can find alternative uses for them.

- Q: How does tinplate contribute to the overall ease of opening and closing packaging?

- Tinplate contributes to the overall ease of opening and closing packaging by providing a strong and durable material that can be easily shaped into various packaging forms. It offers excellent corrosion resistance, ensuring that the packaging remains intact and functional. Additionally, tinplate can be easily formed into easy-to-use closures, such as twist-off caps or pull tabs, enabling convenient opening and closing of the packaging without requiring any additional tools.

- Q: Can tinplate be used for packaging frozen foods?

- Yes, tinplate can be used for packaging frozen foods. It has excellent durability and resistance to temperature fluctuations, making it suitable for preserving the quality and freshness of frozen food products. Additionally, tinplate offers a high level of protection against moisture, light, and oxygen, further ensuring the integrity of the frozen food during storage and transportation.

- Q: How does tinplate impact the overall product safety?

- Tinplate greatly enhances the overall product safety as it acts as a protective barrier against contamination, corrosion, and damage. It safeguards food and beverages from harmful substances, prevents the migration of metals into the contents, and preserves the product's freshness and quality. Additionally, tinplate's durability and resistance to mechanical stress ensure that the packaging remains intact, minimizing the risk of product spoilage or injury to consumers.

- Q: Can tinplate packaging be used for frozen or refrigerated goods?

- Yes, tinplate packaging can be used for frozen or refrigerated goods. Tinplate is a durable and corrosion-resistant material that can withstand low temperatures without compromising the quality and safety of the packaged items. It provides a protective barrier against moisture, light, and oxygen, ensuring the preservation of frozen or refrigerated goods.

- Q: Can tinplate be used for packaging products with sensitive electronic components?

- No, tinplate cannot be used for packaging products with sensitive electronic components as it can cause electromagnetic interference and potentially damage the components.

Send your message to us

Printed Tinplate, Imported Printing Machine, JIS G3303

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords