Printed Packaging Tape South Africa - Masking Film with Crepe Paper Masking Tape and HDPE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 30000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

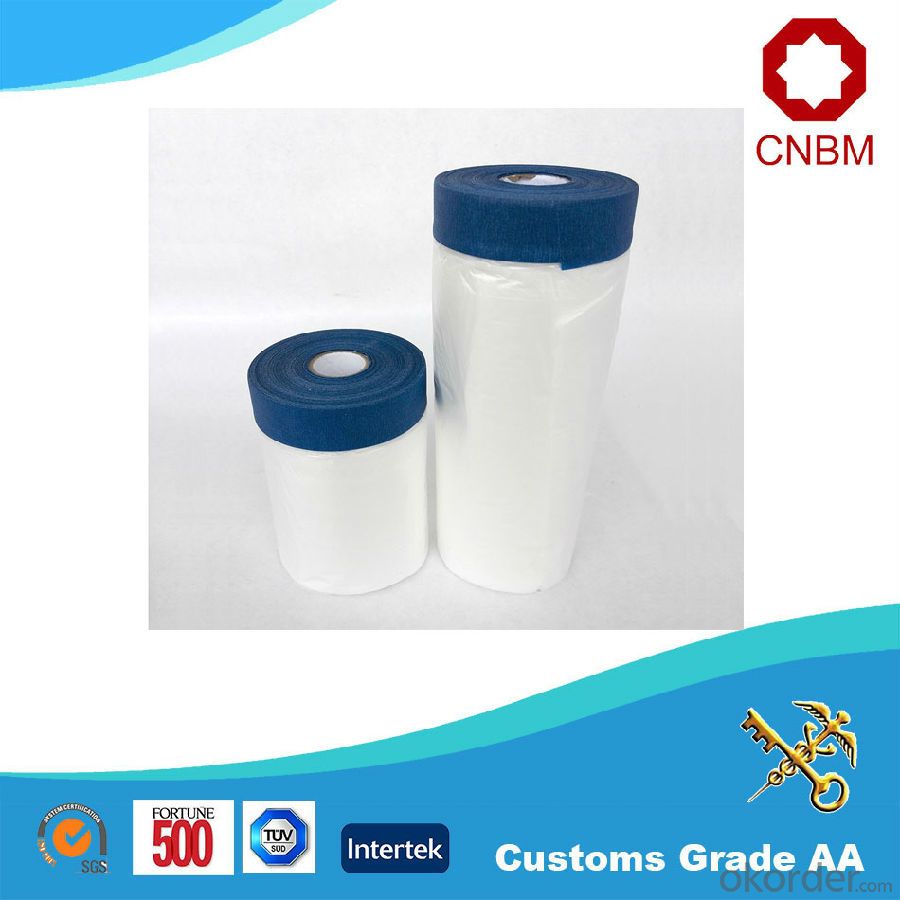

Masking Film with Crepe Paper Masking Tape and HDPE

1. Structure of Masking Film Description

Masking Film is of HDPE film and masking tape. Pretaped with Masking Tape, which is sunlight stable and gives the user 7-day clean removal. A convenient, pretaped plastic film which unfolds to cover and protect various surfaces while painting. Specially treated film clings to surfaces and is easy to clean up.

2. Main Features of Masking Film

Multi-Folded easy to use;

Strong and Flexible;

Competitive price

Indoor/outdoor painting

Sunlight stable even on glass

3. Masking Film Images

4. Masking Film Specification

Tape Size | Rolls/Carton | Weight/Roll(kg) | Jointing Material | Temperature Resistance |

330mm*30M | 20 | 0.12 | Crepe parer | -5—60°C |

550mm*30M | 50 | 0.17 | Crepe parer | -5—60°C |

1100mm*30M | 25 | 0.30 | Crepe parer | -5—60°C |

1400mm*30M | 10 | 0.39 | Crepe parer | -5—60°C |

5. FAQ

Q1. Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

Q2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

Q3. What is the main sizes of masking film?

4mx2.5m,4mx5m, 4mx6m, 4mx8m, 4mx10m, 4mx12.5m, 2mx25m, 2mx50m

6ftx12ft, 8ftx12ft, 9ftx12ft, 10ftx20ft, 9x400ft

- Q: Is packaging tape safe to use on delicate items?

- The safety of using packaging tape on delicate items varies depending on the type of tape and how it is applied. Certain packaging tapes are specifically made for delicate items, minimizing the risk of damage through features like low tack adhesive or gentle release properties. These tapes, commonly known as "low-tack" or "gentle" tapes, are often transparent. When using packaging tape on delicate items, it is crucial to apply it carefully and securely, avoiding excessive force or pressure. It is recommended to test the tape on a small, inconspicuous area of the item first to ensure it does not cause harm or leave residue. Moreover, it is advisable to wrap delicate items with protective materials like bubble wrap or tissue paper before applying the tape. This extra layer of cushioning and protection can be beneficial. If you are uncertain about the safety of using packaging tape on a specific delicate item, it is always best to consult with the manufacturer or seek professional advice. They can provide guidance on the most suitable packaging materials and methods to ensure the safety of your delicate items during transit or storage.

- Q: How does the tape used for packing the finished product in the workshop be accounted for?

- Bank deposits (or accounts payable, etc.)Lead in:The cost of production (or manufacturing expense)Revolving material - packaging

- Q: How does packaging tape perform on non-porous surfaces?

- Packaging tape performs exceptionally well on non-porous surfaces. Its strong adhesive properties enable it to stick firmly to materials like plastic, glass, or metal, ensuring that the packaging remains securely sealed. The tape's ability to withstand different environmental conditions, such as temperature changes or moisture, further enhances its performance on non-porous surfaces.

- Q: What course of packing and cartons do we use for our company?

- The raw material accounts for all the materials in the inventory of the enterprise, including the planned costs and actual costs of raw materials and main materials, auxiliary materials, purchased semi-finished products, repair parts, packaging materials, fuels, etc..

- Q: Sealing tape sales skills and knowledge, please explain to professionals! Help, please

- Sales strategy.What do you sell in the sales process?Answer: myself1, the world's first car sales Jo Gilad said: "I do not sell my Chevrolet car, I sell myself."";

- Q: Can packaging tape be recycled?

- Yes, packaging tape can be recycled, but it depends on the type of tape and the recycling facilities available in your area. Most commonly used packaging tapes, such as clear or brown polypropylene tape, cannot be recycled with regular paper or plastic waste. However, some recycling centers accept certain types of tapes for recycling, such as those made from paper or with water-based adhesives. It is important to check with your local recycling center to determine if they accept packaging tape for recycling and what specific requirements they have. Additionally, removing the tape from cardboard boxes before recycling them can help improve the recycling process. If recycling is not an option, reusing packaging tape or disposing of it properly in the regular trash is recommended.

- Q: Can packaging tape be used for sealing packages with medical or pharmaceutical products?

- Indeed, packaging tape can certainly serve as a means to seal packages containing medical or pharmaceutical items. Nonetheless, it is crucial to take into account the precise requirements and regulations pertaining to packaging within the medical and pharmaceutical sectors. Such industries often uphold rigorous standards concerning packaging materials, aiming to guarantee the safety, soundness, and adherence to regulatory guidelines of the products. Consequently, it is advisable to opt for packaging tape specifically formulated and authorized for use in medical or pharmaceutical contexts. These tapes are typically composed of moisture-resistant and tamper-proof materials, ensuring a robust seal to safeguard the package's contents. By utilizing approved packaging tape, the quality and integrity of medical or pharmaceutical products can be preserved throughout storage and transportation.

- Q: How does packaging tape perform on rubber surfaces?

- Rubber surfaces can be effectively secured using packaging tape, which has been designed with adhesive that adheres well to various materials, including rubber. When applied correctly, packaging tape creates a strong bond, ensuring the secure packaging or fastening of materials. It is important to consider that the effectiveness of packaging tape on rubber surfaces may vary depending on the specific type of rubber and the condition of the surface. In certain instances, the tape may not adhere as strongly to certain types of rubber, particularly if the surface is rough or dirty. To achieve optimal adhesion, it is always advisable to clean and dry the rubber surface before applying packaging tape. Additionally, extreme temperatures and moisture can impact the performance of packaging tape on rubber surfaces. Therefore, it is recommended to store and use the tape within the recommended temperature range and avoid exposing it to excessive moisture. In general, packaging tape is a reliable and secure option for bonding materials on most rubber surfaces, making it suitable for packaging and securing purposes.

- Q: How does packaging tape perform on fabric or textile surfaces?

- Packaging tape typically does not perform well on fabric or textile surfaces. While it may adhere temporarily, it does not provide a strong bond on these materials and is not designed to withstand the flexibility and movement of fabrics. Additionally, the adhesive on packaging tape may leave residue on the fabric or even damage it when removed. Therefore, it is not recommended to use packaging tape on fabric or textile surfaces. Instead, it is advisable to use specialized fabric tapes or sewing techniques for any applications involving fabrics.

- Q: How does packaging tape perform on rough or uneven surfaces?

- Packaging tape typically does well on rough or uneven surfaces, thanks to its adhesive properties that allow it to stick firmly to most surfaces, even those that aren't perfectly smooth. The tape is designed to mold itself to the shape of the surface, ensuring a tight seal and preventing any possible lifting or peeling. However, it's important to note that the effectiveness of packaging tape on rough or uneven surfaces can vary depending on the specific type and quality of the tape being used. Some tapes may have stronger adhesion or more flexible backing materials, which can further improve their performance on rough or uneven surfaces. In certain situations, it may be necessary to apply more pressure or use multiple layers of tape to ensure a secure bond. Moreover, it's worth considering alternative packaging materials, like stretch film or strapping, for particularly rough or irregular surfaces, as they may offer a more dependable solution.

Send your message to us

Printed Packaging Tape South Africa - Masking Film with Crepe Paper Masking Tape and HDPE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 30000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords