Prime Hot Rolled Coil HR Steel Coil China Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Product Introduction

Product name: Hot rolled steel coil Material:Q195,Q235,SS400,SM400(A.B),ST37-2,ST37-3,1010-1050,S235(JR.J0.J2G3.J2G4)

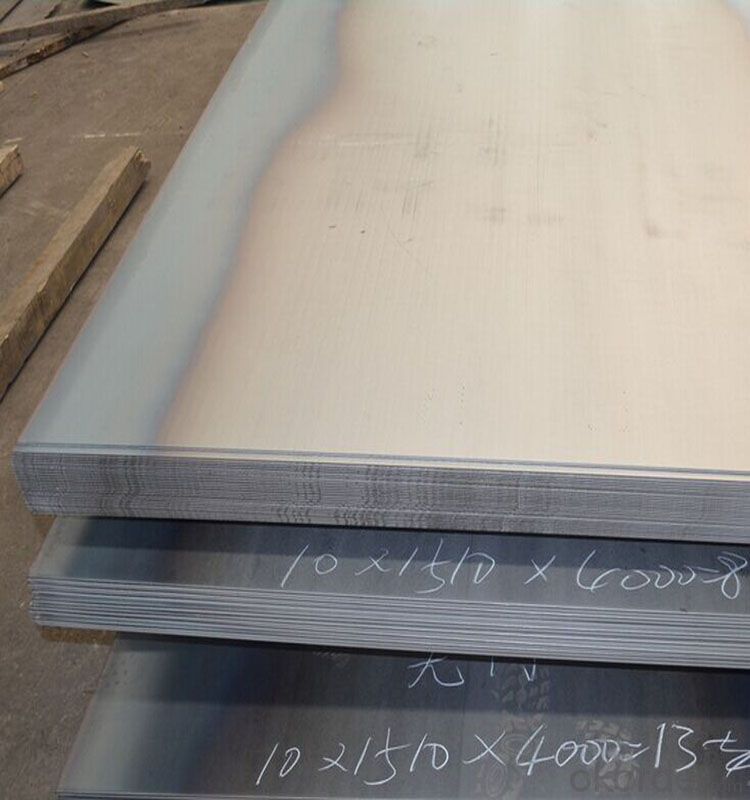

Thickness: 1.5-50mm

Width: 300-2500mm

Application: widely used in construction, household appliance, automobile, light industry, etc

Commodity | Hot rolled steel coil |

Technical Standard: | JIS,GB,DIN,BS,ASTM |

Grade | SS400,Q235,A36,ST-37 |

Width | 300mm to 2500mm |

Thickness | 1.5mm to 50mm |

Surface treatment | Oiled,anneals |

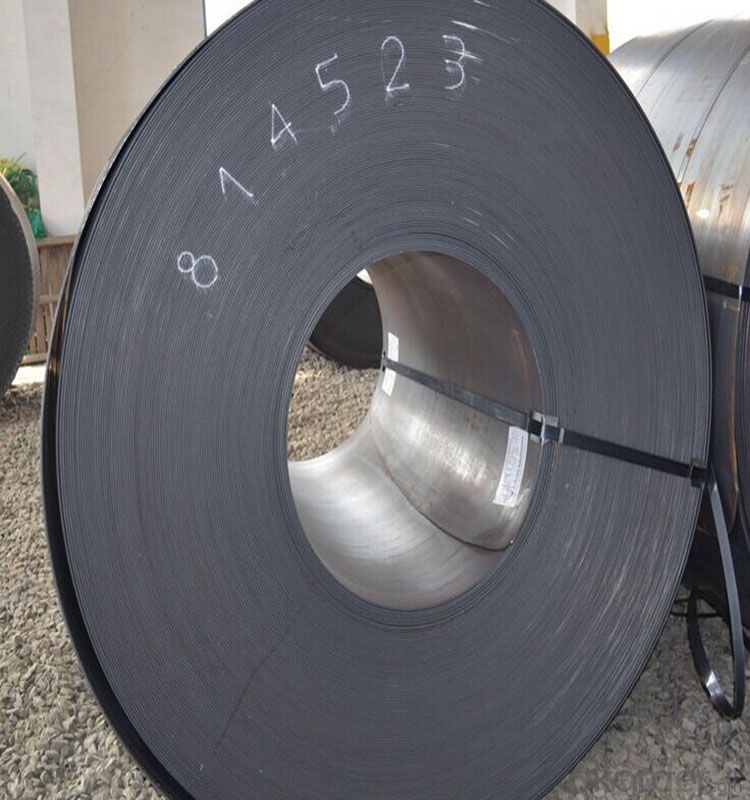

ID coil | 508mm or 610mm |

Coil weight | 3-10 tons as clients's requirements |

Thickness Tolerance | +/-0.15mm |

Width Tolerance | +/-3mm |

Price terms | FOB, CFR ,CIF, CNF ,DAP, etc |

Packaging Details: | Standard export packing or according to clients required |

delivery time | Within 15work days after deposit received. |

Payment Terms: | T/T Or L/C at sight |

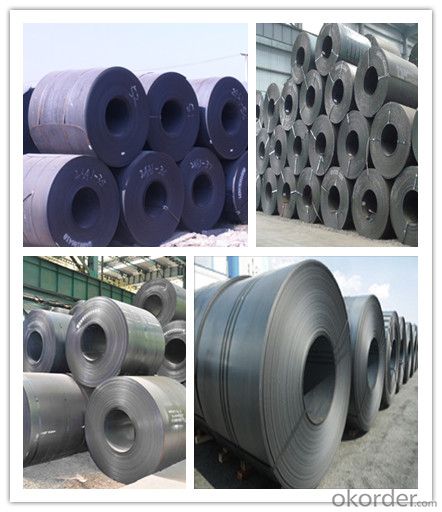

2.Product Photos

3.Service

- Q: What are the quality control measures for steel coils?

- Quality control measures for steel coils typically include various inspections and tests to ensure that the coils meet the required standards and specifications. These measures often involve visual inspections to identify any surface defects or irregularities, such as cracks, dents, or scratches. Additionally, dimensional checks are performed to verify the coil's size, shape, and weight. Other quality control measures may involve conducting mechanical tests, such as tensile strength and hardness tests, to assess the strength and durability of the steel coils. Overall, these measures aim to guarantee that the steel coils are of high quality and suitable for their intended applications.

- Q: so i've started learning to play guitar in the past few weeks, and i'm using my sister's old guitar which isn't in very good condition, so i'm planning on buying a new one, but which would be better to buy, nylon string or steel string?

- It rather relies upon on what type of music you're enjoying, nylon string guitars have a mellow, softer tone than steel strings, the feel of the nylon strings (a minimum of to me) are reliable, in my opinion, i might ought to declare nylon is extra suitable, large for finger choosing and a effective tone. once you're searching for a guitar, you are able to flow out to a close-by guitar save, and attempt the two out for your self, in straight forward terms then will you comprehend for specific.

- Q: What are the different types of steel coil processing equipment?

- There are several different types of steel coil processing equipment, including coil slitting machines, coil cut-to-length machines, coil leveling machines, and coil edge trimming machines. Each of these machines serves a specific purpose in the steel coil processing industry, helping to efficiently and accurately cut, shape, and prepare steel coils for various applications.

- Q: What are the dimensions of steel coils used in the agricultural structure industry?

- The dimensions of steel coils utilized in the agricultural structure sector may differ based on the particular application and requirements at hand. Nevertheless, standard dimensions for steel coils in this industry span from 0.5mm to 3mm in thickness and from 600mm to 1500mm in width. The length of the coils can also vary, but typically falls between 1000mm and 3000mm. These dimensions afford flexibility in constructing agricultural structures like barns, sheds, and storage facilities, all while ensuring ample strength and durability. It is worth noting that precise dimensions may vary depending on the manufacturer and the unique demands of the agricultural project.

- Q: How are steel coils inspected for coil weight accuracy after processing?

- Steel coils are typically inspected for coil weight accuracy after processing by using weighing scales or load cells that are capable of accurately measuring the weight of the coil. The coil is placed on the scale or load cell, and the weight is compared to the target weight specified for that particular coil.

- Q: I was curious to what type of steel I should get if I wanted something that kept its edge longer than 154cm but is still just as stainless. I don't know much about knife steels inform me please?

- 154cm is a very good knife steel, the problem is in the heat treating. Stainless should be cryo treated to get all it can offer. That being said, if you really want to drop some coin, look at getting one made from CPM 440V. Stainless isn't as strong as carbon but on a smaller knife works well. You might also look for D-2 Tool steel. There are factory knives that are made of that.

- Q: What is the process for uncoiling and recoiling steel coils?

- The process for uncoiling and recoiling steel coils involves various steps. Firstly, the steel coil is securely placed on a mandrel or a coil car. Next, the coil is unfastened or cut to release the bands holding it together. Then, a suitable uncoiling machine is used to gradually unwind the coil, ensuring it is done in a controlled manner to prevent damage or accidents. Once the desired length of steel is unwound, it can be cut or sheared to the required size. To recoil the steel, it is fed through a recoiling machine that winds it back onto a new core or mandrel. Proper tension is applied during this process to ensure a tightly wound coil. Finally, the recoiled steel coil is secured with bands or straps for transportation or storage purposes.

- Q: What are the common coil storage methods?

- The common coil storage methods include stacking in a vertical or horizontal position, using coil cradles or racks, and utilizing coil drums or shafts for secure storage.

- Q: As we all know Shaq killed the movie Steel by suckin so bad but does anyone know what happened to the comic book version.

- Steel's own series was cancelled around issue #50, after which he went on to a co-starring role in Superman: The Man of Steel. Steel was eventually injured in a battle with Darkseid, at which time his niece Natasha took on the role of Steel. John Henry recently resurfaced in his heroic identity in 52, where he's been injected with Lex Luthor's metagene, making his body living stainless steel.

- Q: How are steel coils used in the manufacturing of automotive fuel tanks?

- Steel coils are used in the manufacturing of automotive fuel tanks as they are shaped and welded to form the structure of the tank. The coils provide strength and durability to the tank, ensuring it can withstand the pressure and impact of the fuel. Additionally, the steel coils are often coated to prevent corrosion and ensure longevity of the fuel tank.

Send your message to us

Prime Hot Rolled Coil HR Steel Coil China Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords