Prime Grade MR Tinplate For Food Cans, CA BA

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Usage

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Quality

As a state owned company and a large tinplate supplier in China, our tinplate quality ranks 1st level in China, similar to Bao Steel, Posco etc.

3. Specification

standard: GB/T2520, JIS G3303, DIN EN10202

Material: MR /SPCC

Thickness available: 0.16-0.50MM

Width available: 600~1050MM

Temper grade: T1 – DR8

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g and others

Package: sea worthy export package.

Applications: Tin can for chemicals & paint cans, industrial cans, food cans

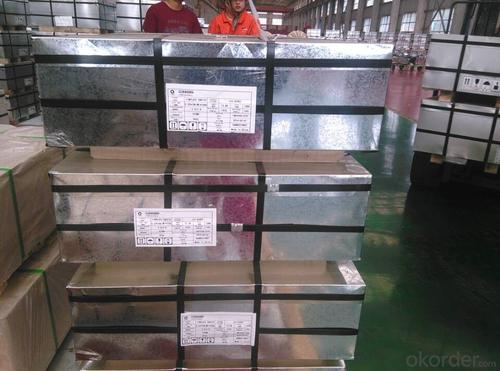

4. Our factory photo & equipments

5. Our Markets:

now our tinplate has been sold to more than 50 countries, including Europe country, Gulf Area, South American, South Afric etc.

6. Our Overseas Wareouses:

Furthermore, in the year 2014, we have more than 10 overseas warehouses all over the word, located in KSA, UAE, Oman, Russia, Kuwait, Qatar, Oman, Chile, Brazil etc.

7. FAQ

a. what's the annual output?

about 500,000 tons per year.

b. where's the raw matrial from?

our hot rolled coil is purchased from Capital Steel and other state owned mill, with quite good quality.

c. how long is the delivery time?

normally for SPCC about 45~55 days, while 65~75 days for MR material

d. how to control the quality during production process?

inside our workshop, we have MES syestem. It realizes the optimization of the production procedure in the workshop. It could record each step of the whole production procedures, and if some problem appears, factory could easily found and take action, it’s quite helpful to monitor and control the quality.

- Q: How does tinplate contribute to the overall versatility of packaging?

- Tinplate contributes to the overall versatility of packaging by offering a wide range of benefits. Its durability, corrosion resistance, and ability to withstand high temperatures make it ideal for preserving and protecting various products. Tinplate can be easily molded into different shapes and sizes, making it suitable for diverse packaging requirements. Additionally, its metallic appearance provides an attractive and premium look to the packaging, enhancing the brand image. Overall, tinplate's versatility makes it a popular choice for a wide range of products, from food and beverages to cosmetics and electronics.

- Q: What are the challenges faced in the recycling of tinplate?

- One of the main challenges in the recycling of tinplate is the separation of tin from the steel base. Tinplate consists of a thin layer of tin coated on steel, and separating these materials requires specialized equipment and processes. Additionally, the presence of other contaminants, such as paint or coatings, can further complicate the recycling process. Proper sorting and cleaning of tinplate waste is necessary to ensure efficient recycling and minimize the loss of valuable materials.

- Q: How does tinplate packaging protect against moisture and oxygen?

- Tinplate packaging protects against moisture and oxygen due to its unique properties. The tin coating acts as a barrier, preventing the penetration of moisture and oxygen into the packaged product. It creates a protective layer that effectively shields the contents from these elements, ensuring their quality and freshness over an extended period of time.

- Q: How is tinplate recycled and what are its recycling rates?

- Tinplate is recycled through a process called "tinplate recycling" where it is collected, sorted, and melted down to create new products. The recycling rates of tinplate vary depending on factors such as regional recycling infrastructure, collection efforts, and consumer awareness. However, on average, tinplate has a relatively high recycling rate of around 80-90% in many developed countries.

- Q: Can tinplate be used for packaging of flammable liquids?

- Yes, tinplate can be used for packaging of flammable liquids. Tinplate is a durable and corrosion-resistant material that provides a strong barrier against external elements, including flammable liquids. It is commonly used in the packaging of various products, including flammable liquids, due to its ability to withstand the potential hazards associated with these substances.

- Q: What are the common challenges in recycling tinplate packaging?

- Some common challenges in recycling tinplate packaging include the separation of tinplate from other materials, such as plastic or paper, which can be time-consuming and costly. Additionally, the removal of any residual contents or labels from the tinplate can be challenging. The recycling process may also be complicated by the presence of coatings or laminations on the tinplate. Finally, the availability of recycling facilities specifically equipped to handle tinplate packaging can be limited, leading to logistical difficulties in the recycling process.

- Q: How does tinplate contribute to the overall aesthetics of packaging?

- Tinplate contributes to the overall aesthetics of packaging through its unique and eye-catching appearance. Its shiny and smooth surface, along with its ability to be printed with vibrant and intricate designs, adds a touch of elegance and sophistication to various products. Additionally, tinplate's durability and versatility allow for the creation of intricate shapes and designs, enhancing the overall visual appeal of packaging.

- Q: What are the safety considerations when handling tinplate?

- When handling tinplate, several safety considerations should be kept in mind. Firstly, it is important to wear appropriate personal protective equipment (PPE) such as gloves and goggles to protect against cuts, abrasions, and potential eye injuries. Additionally, tinplate can be sharp, so caution should be exercised to avoid getting injured by its edges. It is also essential to handle tinplate with care to prevent any damage or deformation, as sharp edges or bent corners can pose a safety risk. Lastly, proper lifting techniques should be employed to avoid strain or back injuries when moving or stacking tinplate.

- Q: Can tinplate packaging be used for microwaveable products?

- No, tinplate packaging should not be used for microwaveable products as it can cause sparks and potential fire hazards.

- Q: Can tinplate be used for agricultural applications?

- Yes, tinplate can be used for agricultural applications. It is commonly used for the packaging of agricultural products such as canned food, seeds, and agricultural chemicals. Tinplate offers protection against moisture, pests, and contamination, making it suitable for preserving and transporting agricultural goods. Additionally, its durability and resistance to corrosion make it a reliable choice for various agricultural uses.

Send your message to us

Prime Grade MR Tinplate For Food Cans, CA BA

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords