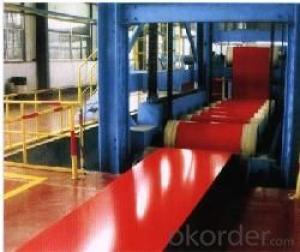

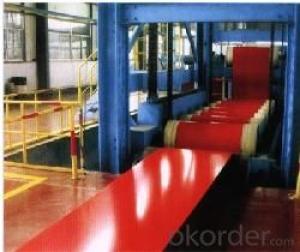

Prepainted galvalume steel coils RAL Color No.

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

colour coated steel

painting colour steel , zinc coated steel , lead coated steel

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | DX51D,SGCC,SPCC,CGCC | Thickness: | 0.17-1.5mm |

Place of Origin: | Taian China (Mainland) | Brand Name: | HengJi | Model Number: | HJ |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | RAL color cremated, oiled, skin passed |

Application: |

building metal roofing components,house appliance | Width: | 914-1250mm | Length: | customized |

price: | favorable price |

|

Packaging & Delivery

Packaging Detail: | standard export packing or customized |

Delivery Detail: | 15 days after prepayment |

Specifications:

galvanized steel coil:

1.Thickness:0.17mm-1.5mm

2.Zinc coated:40g-275g/2

3.Standard:dx51d+z,sgcc

We manufacture Galvanized Steel Coils,Pre-painted Galvanized Steel Coils , etc

Prepainted steel coil features:

1. Zinc coating :40-120g(as reauired)

2. thickness:0.17-1.2mm

3. width:914-1250mm(900mm,1215mm,1250mm,1000mm the most common)

4. coil id:508m610mm

5. coil weight: 3-12(as required)

6. surface treatment:RAL color

Galvanized steel coil features:

1. Zinc coating :40-275g( as required)

2. thickness:0.17-1.2mm

3. width:914-1250mm(900mm,1215mm,1250mm,1000mm the most common)

4. coil id:508m610mm

5. coil weight: 3-12(as required)

6. surface treatment: cremated, oiled, skin passed

7. Spangle: regular,small, zero

8.Application: With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

Product name | steel coil,galvanized steel,galvanized steel coil |

Material | DX51D, SGCC, SPCC, CGCC, DX51D |

Normal thickness | 0.17-1.2mm |

Normal width | 900mm,914mm, 1000mm, 1200mm, 1220mm, 1250mm |

Coil weight | 3-12ns |

Certificate | BV & SGS |

Original | Shandong,China |

Payment terms | L/C or T/T |

Delivery time | within 15 ~ 25 days after 30% prepayment |

- Q: How are steel strips used in the manufacturing of tools?

- Steel strips are commonly used in the manufacturing of tools as they provide the necessary strength and durability required for tool construction. These strips are often shaped, bent, and formed into various tool components such as blades, handles, and casings. The steel strips undergo processes like cutting, grinding, and heat treatment to enhance their hardness and toughness, making them suitable for enduring the demands of tool usage.

- Q: How are steel strips used in the production of wind turbines?

- Steel strips are used in the production of wind turbines for various purposes such as making the tower, rotor blades, and other structural components. These strips are shaped, welded, and assembled to create the tower sections, providing the necessary height and strength to support the turbine. Additionally, steel strips are often used in the manufacturing of rotor blades, which require strong, lightweight materials to efficiently capture wind energy.

- Q: What are the different surface engraving methods for steel strips?

- There are several surface engraving methods for steel strips, including laser engraving, etching, chemical engraving, and mechanical engraving. Each method has its own advantages and is suitable for different applications. Laser engraving offers high precision and can create intricate designs, while etching uses chemicals to remove material and create patterns. Chemical engraving involves the use of acid or other chemicals to etch the surface, and mechanical engraving uses cutting tools to physically remove material. The choice of method depends on factors such as desired design complexity, production volume, and cost considerations.

- Q: Are steel strips suitable for making electrical connectors?

- Without a doubt, steel strips are a suitable option for fabricating electrical connectors. These strips possess numerous advantages that have contributed to their widespread popularity in the realm of electrical connectors. First and foremost, steel serves as an exceptionally conductive material, thereby ensuring the efficient transmission of electrical currents. This quality makes steel strips the perfect conduit for electrical signals, guaranteeing a secure and steadfast connection. Moreover, steel boasts impressive strength and durability, which greatly enhance the longevity and reliability of electrical connectors. Steel strips can withstand even the harshest environmental conditions, including extreme temperatures, moisture, and corrosion, thus ensuring the continued functionality and safety of the connectors in a variety of circumstances. Furthermore, steel strips can be easily molded and fashioned into a plethora of connector designs, allowing for unparalleled versatility and customization. This adaptability enables the creation of connectors that are tailored to specific electrical applications and requirements. Additionally, steel strips present a cost-effective alternative compared to other materials utilized in electrical connectors, making them an astute choice for manufacturers and end-users alike. In conclusion, the qualities of excellent conductivity, durability, adaptability, and cost-effectiveness render steel strips a truly fitting option for the production of electrical connectors.

- Q: Are steel strips suitable for outdoor applications?

- Yes, steel strips are suitable for outdoor applications. Steel is known for its durability, strength, and resistance to corrosion, making it an ideal material for outdoor use. Additionally, steel strips can withstand various weather conditions, including rain, snow, and sunlight, without significant damage or deterioration.

- Q: Are steel strips suitable for electrical grounding applications?

- Yes, steel strips are suitable for electrical grounding applications. They provide a strong and durable grounding solution due to their high conductivity and ability to dissipate electrical charges effectively. Additionally, steel strips are resistant to corrosion, making them a reliable choice for long-term grounding installations.

- Q: Can steel strips be used in railway tracks?

- Yes, steel strips can be and are commonly used in railway tracks.

- Q: What are the different surface buffing methods for steel strips?

- There are several surface buffing methods for steel strips, including mechanical buffing, chemical buffing, and electrochemical buffing. Mechanical buffing involves using abrasive materials or pads to physically remove imperfections from the surface of the steel strip. Chemical buffing utilizes chemical compounds or solutions to dissolve or remove surface contaminants, while electrochemical buffing uses an electric current to selectively remove material from the surface of the steel strip.

- Q: What are the different treatments applied to steel strips for specific applications?

- There are several different treatments that can be applied to steel strips for specific applications. These treatments are designed to enhance the properties of the steel and make it more suitable for its intended use. One common treatment is heat treatment, which involves heating the steel strip to a specific temperature and then cooling it rapidly. This process can be used to improve the hardness, strength, and toughness of the steel. Heat treatment can also be used to alter the microstructure of the steel, which can improve its machinability or resistance to wear. Another treatment commonly applied to steel strips is surface coating. This involves applying a thin layer of another material to the surface of the steel. The coating can provide protection against corrosion, improve the aesthetics of the steel, or enhance its performance in specific environments. Some common types of surface coatings include zinc plating, galvanizing, and powder coating. Some steel strips may also undergo cold rolling or annealing processes. Cold rolling involves passing the steel strip through a series of rollers at room temperature to reduce its thickness and improve its surface finish. Annealing, on the other hand, involves heating the steel strip to a specific temperature and then cooling it slowly to relieve internal stresses and improve its ductility. In addition to these treatments, steel strips can also be subjected to various mechanical processes, such as bending, cutting, or shaping, to achieve the desired dimensions and form. These processes can be performed before or after any of the above treatments, depending on the specific requirements of the application. Overall, the choice of treatment for a steel strip depends on the specific application and the desired properties of the final product. By applying the appropriate treatment, steel strips can be tailored to meet the needs of various industries, such as automotive, construction, and manufacturing.

- Q: Can steel strips be used in the manufacturing of kitchen appliances?

- Yes, steel strips can be used in the manufacturing of kitchen appliances. Steel is a versatile and durable material that is commonly used in the manufacturing industry. Steel strips can be used to make various components of kitchen appliances, such as the outer casings, internal structures, and even the cooking surfaces. Steel is known for its strength, heat resistance, and corrosion resistance, making it an ideal choice for kitchen appliances that are exposed to high temperatures and moisture. Additionally, steel can be easily molded, shaped, and welded, allowing manufacturers to create complex and precise designs for kitchen appliances. Overall, steel strips are a commonly used material in the manufacturing of kitchen appliances due to their durability, versatility, and ability to withstand the demanding conditions of a kitchen environment.

Send your message to us

Prepainted galvalume steel coils RAL Color No.

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords