Prefabricated Wall Panels from CNBM China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

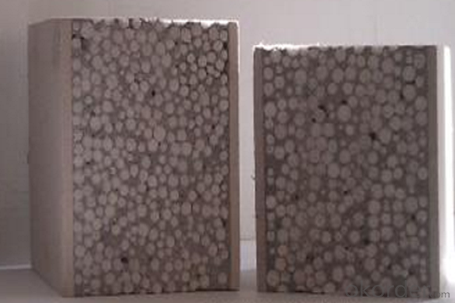

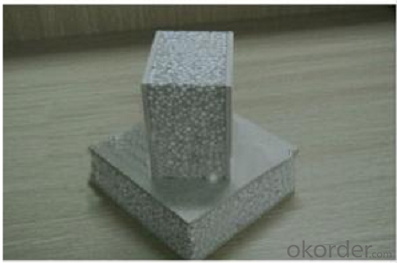

Composition: EPS+cement+calcium silicate board

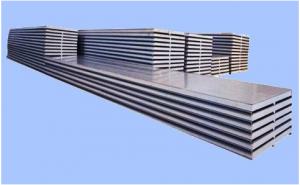

Package (20GP)

Specification (mm) | Quantity (pcs) | Area (sqm) | Weight (kg) |

2270*610*60 | 306 | 424 | 19500 |

2270*610*75 | 252 | 349 | 18200 |

2270*610*90 | 207 | 287 | 17300 |

2270*610*100 | 189 | 262 | 17300 |

2270*610*120 | 153 | 212 | 15000 |

2270*610*150 | 126 | 175 | 13200 |

Usage

JY wall panel is widely used in the partition of highrise buildings, industrial plants, office buildings,

residential houses, work shed and other constructions. It can be also used as non load bearing structure of

washroom, kitchen and renovation of old houses. And it's particularly applicable to places with high fireresistance requirement.

Project

Certificate

Q1: How soon can we receive the goods after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q2: How to make a quick resolution for after service?

A2: OKorder and our manufacture both have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Q3: How do we guarantee the quality?

A3: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q: Paper honeycomb sandwich panels about how much the price

- Do not know what you do with, I see you most recently has been consulting honeycomb board problems, I do pp honeycomb board

- Q: 100 thick composite sandwich board how much money a square meter upper plate 0.6 lower 0.4

- Sandwich panels are also different from Yan Yan or benzene board or glass wool

- Q: Aluminum magnesium manganese composite sandwich panel 90 degrees right angle how to fold

- Certainly the aluminum magnesium manganese plate light, the proportion of aluminum magnesium manganese plate is 4.71, the proportion of color steel plate is 7.85.

- Q: What are the benefits of rock wool sandwich panels and what are the advantages?

- Shandong Yonggu Building Materials Co., Ltd. specializes in the production of rock wool sandwich panels, rock wool sandwich panels with fire, thermal insulation, sound-absorbing sound insulation, beautiful appearance, convenient construction, green and other excellent performance. Widely used in large industrial plants, warehouses, gymnasiums, supermarkets, hospitals, cold storage, activities room, building plus layer, clean workshop and the need to heat insulation fire places. ???? Hope to help you, if there is any doubt, look at our company's website, there are detailed details of the product, in search company name can be found, I wish you a good mood.

- Q: Is the foam sandwich board one meter high?

- Some we do the highest of 21 meters

- Q: What is the wall of the steel wire mesh in the building company? Is it easy to fix it again?

- Permanent wall is a new type of steel mesh sandwich panels, building without bricks, stay fast, low cost, Dongnuanxialiang, strong earthquake, energy saving, exclusive rural building materials, galvanized steel wire mesh Meet the use of functional and structural requirements of the space grid, the middle filled with molded polystyrene foam board or rock wool board and the formation of the board, in the Chinese industry standard specification referred to as CS board. CS board on both sides of the configuration of the longitudinal reinforcement, spray (wiping) concrete and the formation of the composite board wall, referred to as CS wall panels, that is, steel frame concrete composite panel wall. With fire insulation and anti-vibration can be secondary maintenance characteristics, far better than the effect of brick building.

- Q: So here's the deal, I really need to run the oven cleaner, and I know how much smoke will come out of the oven, and I have a wired smoke alarm directly above the stove (landlord's design not mine). If I cover it with a sandwich bag, will that slow down the chance of it going off or increase the chance? Yes I know to remove the bag directly after the oven cleaner is done for obvious saftey reasons.

- I would just go to the electrical panel in the basement and turn off the breaker. There should be a separate breaker for the smoke alarms. Just remember to turn them back on.

- Q: what is the specification of Alumni foil used in the sandwich panel(foam) as roofing?

- Alumni do not make good foil material........

- Q: Sandwich board is used to do what ah ??

- Should be "sandwich board" was right. Sandwich panel products are composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the composition of the polymer core insulation. These sandwich panels are easy to install, lightweight and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. The forming of the outer steel sheet takes into account the structural and strength requirements, and takes into account the appearance, the inner layer is formed into a flat plate to suit various needs. Sandwich panels for large industrial plants, warehouses, gymnasiums, supermarkets, hospitals, cold storage, activities, building plus layer, clean workshop and the need to heat insulation fire places.

Send your message to us

Prefabricated Wall Panels from CNBM China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords