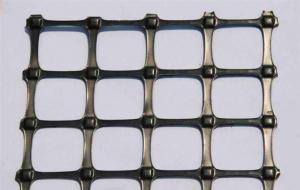

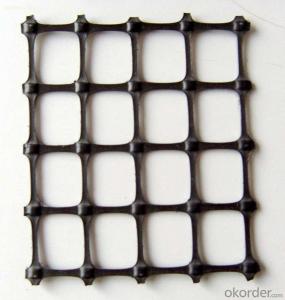

Neoloy Geocells PP Unixial Geogrid for Road, Railway, Highway, and Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Uniaxial Plastic Geogrid for road railway highwayprojects Made from polymerand nano scale carbon black by extrusion technology

Specification ofUniaxial Plastic Geogrid for road railway highway projects:

I. TGDG35, TGDG50, TGDG80, TGDG120, TGDG160, TGDG260, TGDG300 etc

2. Lm t0 3m in roll width

Property of UniaxialPlastic Geogrid for road railway highway projects:

I. Roadbed reinforcement, improve stability and bearing capacity

2. Prevent roadbed from deformation and crack due to roadbed material wash off

3. Retaining wall bearing capacity improvement

Application of UniaxialPlastic Geogrid for road railway highway projects:

I. Roadbed reinforcement in highway

2. Municipal road, railway, airport runway

3. Dam reinforcement

4. Garden fence and river bank

5. Retaining wall reinforcement in highway

Production standard ofUniaxial Plastic Geogrid for road railway highway projects:

G B/T17689-2008

JT/T 480-2002

- Q: Are geogrids suitable for reinforcing embankments?

- Yes, geogrids are suitable for reinforcing embankments. Geogrids are commonly used in civil engineering projects to provide stability and strength to soil structures, including embankments. They help distribute the load and increase the bearing capacity of the embankment, preventing soil erosion and potential slope failures. Geogrids also enhance the overall durability and longevity of the embankment, making them an effective solution for reinforcement.

- Q: Can geogrids be used in soil stabilization for sports fields?

- Yes, geogrids can be used in soil stabilization for sports fields. Geogrids are commonly used to reinforce and stabilize soil, preventing erosion and improving load-bearing capacity. They can effectively distribute loads and provide stability in sports fields, ensuring a safer and more durable playing surface for athletes.

- Q: What are the quality assurance measures for geogrid installation?

- Quality assurance measures for geogrid installation include: 1. Proper preparation of the subgrade: Ensuring that the subgrade is well-graded, compacted, and free from any debris or vegetation is crucial before geogrid installation. This ensures a stable base for the geogrid and enhances its effectiveness. 2. Correct geogrid selection: Choosing the appropriate type and strength of geogrid based on the specific project requirements and design specifications is essential. This involves considering factors such as load capacity, soil type, and expected performance. 3. Accurate geogrid placement: Ensuring that the geogrid is correctly positioned and securely anchored is vital for its effectiveness. Careful attention should be paid to the alignment, overlap, and anchorage of the geogrid to prevent any shifting or displacement during and after installation. 4. Proper tensioning: Geogrids need to be adequately tensioned to achieve the desired tensile strength and load distribution. This requires following manufacturer guidelines and using appropriate tensioning equipment to achieve the recommended elongation or strain. 5. Regular inspection and testing: Conducting frequent inspections during geogrid installation helps identify any defects, damage, or non-compliance with specifications. Additionally, conducting pull-out tests or other relevant performance tests can verify the geogrid's adherence to the desired strength and load-bearing capacity. 6. Documentation and record-keeping: Maintaining comprehensive documentation of geogrid installation, including materials used, installation procedures, test results, and any deviations or corrective actions taken, ensures traceability and accountability. This documentation can be valuable for quality control and future reference. By implementing these quality assurance measures, geogrid installation can be carried out effectively, ensuring the desired performance and longevity of the geogrid system.

- Q: What are the procedures for using two-way geogrid

- 1 bidirectional geogrid is used to increase the bearing capacity of the road (ground) foundation, and the service life of the Yan Changlu (ground) foundation.2 bidirectional geogrid used to prevent road (ground) surface collapse or crack, keep the ground beautiful and tidy.3 bidirectional geogrid for the construction of convenient, time-saving, labor-saving, shorten the construction period, reduce maintenance costs.

- Q: What are the geotechnical testing items for Subgrade?

- Longitudinal and transverse tensile strength and elongation

- Q: What is the recommended geogrid aperture size?

- The recommended geogrid aperture size depends on various factors such as the soil type, project requirements, and design specifications. It is typically determined through engineering analysis and testing to ensure optimal performance and stability.

- Q: Can geogrids be used in road widening projects?

- Yes, geogrids can be used in road widening projects. Geogrids are commonly used in road construction and rehabilitation projects as they provide a stable base, reduce soil movement, and improve the overall performance of the road. In road widening projects, geogrids can help reinforce the existing road structure, increase load-bearing capacity, and prevent the potential failure of the widened sections.

- Q: Glass steel grille is how to produce

- Glass steel grille (FRP) is a kind of glass fiber reinforced and unsaturated polyester resin, with a lot of space plate material through special processing and compounding, glass steel grille can be used as a structural material, corrosion environment, trench cover, floor platform, the deck of the ship, stairs, plank etc.

- Q: Can geogrids be used in soil reinforcement for pipeline projects?

- Yes, geogrids can be used in soil reinforcement for pipeline projects. Geogrids are commonly used in civil engineering projects to improve soil stability and prevent soil erosion. They are effective in providing reinforcement and reducing the potential for soil settlement, making them suitable for enhancing the stability of pipelines in various soil conditions.

- Q: Glass fiber grille modified asphalt, polyester grille coated PVC.

- Bidirectional welding plastic top net, high strength spiral rib steel wire grid model, integrated 3D Geomat, high strength geogrid, geocell, engineering fiber, geotextile composite geomembrane, whichincludesimportedwetthinfeltproductionline engineering materials used in underground coal mine

Send your message to us

Neoloy Geocells PP Unixial Geogrid for Road, Railway, Highway, and Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords