Power Trowel BPM100-C Electric Type

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

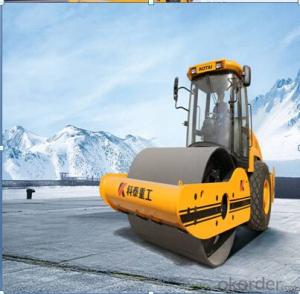

Used for compacting the gravel,soil, asphalt roads, sidewalks, Bridges, car parks, sports venues and the narrow site compaction work. It’s an ideal equipment for highway, municipal departments to build roads, streets, squares.

Easy operation, flexible steering and good welt performance, good shock absorption performance.

Main Product Features:

1. Independent rotating fly wheel, allowing operation in tight corners and in confined spaces;

2. Over-built gear box assures long service life;

3. Heavy weight design to assure a superior finish;

4. Height adjustable handle, deadman switch available, assure operator comfortable & easy control;

5. Centrifugal safety switch, shuts the engine down in the event of the operator loosing control of the unit;

6. Trottle control is optional.

Product Specifications:

Model: HZR60-B

Engine Type: Electric Motor

Power: 3KW

Pan Dimention:100cm

Rotary Speed: 50-100RPM

Packing Size: 105cm x 105cm x 76cm

Weight: 85kg

FAQ:

Q1: Does the Power Trowel use electricity or diesel?

A1: The Power Trowel is equipped with famous brand electricity motor.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 20 workdays.

Q4: If we can produce some Power Trowel according to customers request?

A4: Yes, we can produce Power Trowel according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: How much is the rent for XCMG 303 tire roller?

- Be proficient in loose work and live on site! Hanging broken cable, pipe into the mud five times are many, drag up have to overhaul the new crane to be scrapped in three months, the crane is now looking for a long-term stability of more than 30 tons, required Baochibaozhu package hit penicillin, more than 8000 monthly wages, wages, the boss finds the boss beautiful open

- Q: What are the major components of a vibratory roller?

- There are several kinds of vibratory rollers: single cylinder wheel, double steel wheel, rubber wheel and so on.Take a single cylinder as an example, the main components include engine, hydraulic system, steel wheel, drive axle, cab, electrical system, structural parts, etc.

- Q: How many tonnage vibratory rollers are heavy?

- The vibratory roller is equipped with a vibrator on the static roller, and the compacting operation is done by the weight and the exciting force. There are single wheel, double wheel, tire type, double vibration type, combination type and so on.

- Q: Excavators, forklifts, bulldozers, rollers with the same tonnage fight who badly rank

- when other machine ran first and then driving the main digging sub floor, kill the driver, do not close machine line, so this is a boring the problem is driving technology, the two is to have strategic thinking, the three is not afraid of death.

- Q: When using 20T heavy vibratory roller, what is the backfill thickness per layer?

- When using 20T heavy vibratory roller, the backfill thickness of each layer is less than 30cm.Subgrade construction quality control measures:The quality of the subgrade and the base of the road will directly affect the quality of the concrete pavement.1, subgrade construction, first of all, the surface soil excavation, should be replaced by bad soil, and filling before compaction.

- Q: What's the width of the 12 ton roller?

- According to the operating weight divided into micro (1 tons); small (1-6 tons); medium (6-10 tons), heavy (10-14 tons); super heavy (16 tons) pressing wheel distinction: single steel wheel and double steel wheel, three wheel, tire according to the compaction principle: vibratory and static effect of impact roller, roller, roller combination at present commonly used in Engineering: single.

- Q: 31 How about roller?

- In fact, each enterprise has its product positioning, the use of the object has its choice models considering how to choose from that the highest cost-effective products, eyes of the beholder.

- Q: The rollers are divided into several types

- The roller from the area can be divided into vibroll (RCC) and static (rolling), road roller vibration roller can be divided into 2 6 8 amplitude amplitude, amplitude, and refinement is based on weight and amplitude, exciting force and other distinguished models.

- Q: I need a roller, but the search found different working principles of rollers

- The biggest difference is that the hydrostatic roller is used to press asphalt, that is, the road surface, the road will be used laterVibratory roller is used to press the earth, the road is full of its life, the first few layers of the foundation will be used before the static roller

- Q: What do you mean by "380/275" in the vibratory force (kN) of vibratory roller?

- In the question, 275 did not give the amount of engineering units, I just guess the following is KN.

Send your message to us

Power Trowel BPM100-C Electric Type

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords