Portland® N-TGD belt bucket elevator for tower compound fertilizer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 99 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The special elevator of tower compound fertilizer

The special elevator of tower compound fertilizer has formed a complete manufacturing standard, has established technical post for the industry .

According to professional research and development of new tape bucket product features in the chemical fertilizer industry,

The special materials characteristics of the tower granulation, such as strong corrosive, increasing additive, etc., we should improved machine improvement and process design, otherwise will lead to corrosion of steel member is faster,tape layup will be failure rapidly,the tail tension device will be failure,the incomplete discharge will cause too much of the feed back,the lock is serious,the tail will be taken ash and a series of problems, most similar equipments has these problems at present.

According to these problem, Our company’s elevator has been specific design.

1.The technical features as follows:

1.1 The steel cable belt for bucket elevator has independent intellectual property rights.

1.2 Belt joint device that has independent intellectual property rights of Bucket elevator is made special treated.

1.3 It has improved head device, matches with high wear-resisting vulcanization head wheel and cleaning device.

1.4 It has modified tail device, matches with rod cage and high precision tail wheel.

1.5 Improved strength tension mechanism of parallel four connecting rod and anti-corrosion treatment.

1.6 Shell and hopper are painted professional anti-corrosive paint.

1.7 Reduction scheme of positive pressure

1.8 The fixed technology of hopper has independent intellectual property rights.

1.9 The type of drive is suspension simply supported mechanism .

1.10 Reliable seal of head, and overall built-in tail dust bearing

1.11 The operation of control and protection device is perfect.

2 Technical Features

——Lifting height is up to 140m

——Conveying capacity is up to 1335 m3/h

——Instantaneous material temperature can reach 180°C

3 Model

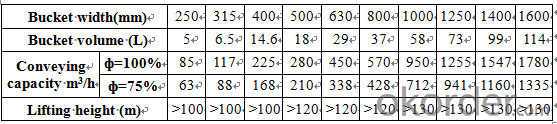

Table of conveying capacities table 1

Notes:a. The bucket volume is the volume when taking water, ф is the material filling ratio.

b. The maximum lifting height is the center distance C between the head shaft and the tail shaft.

- Q: What are the potential defects of the automated material handling system?

- In manufacturing and material handling, the automatic pilot (AGV) has become increasingly familiar. But the shuttle, which is introduced here, is based on the equipment that automatically carries the material in the path of the orbit. Machine commonly used in existent shelves, existent shelves for its high space utilization, accepted by a lot of storage and transportation unit, but forklift truck into the tunnel, because the space is narrow, there are shelves safe hidden trouble. In addition, using forklift and human handling inefficient, high cost, on the basis of the original shelves introducing automation machine, in order to improve the automatization level of the whole line production storage and transportation.

- Q: What is the rational and scientific classification of logistics facilities and equipment

- The operation of loading and unloading and transportation activities in the field of logistics is determined by the smooth operation of the logistics industry. The carrier is divided into two parts: one is handling and handling machinery; Second, transport machinery. Loading and unloading machines include: crane, forklift, container handling and pallet shipment. Transport machinery such as: road transportation of all kinds of truck, train of railway transportation, water transport ships, air transport aircraft, pipeline transport pipeline, and so on. With the development of logistics informatization, networking and systematization, the computer plays an important role in logistics management. Communication devices include telephone, telegraph, e-commerce, wireless tower and so on. Computer and communications equipment connect the whole world of life, culture, politics, economy as a whole, shortens the distance of time and space, we can timely and accurate understanding of the external environment and information and change.

- Q: The wear-resisting parts in the broken machine are mainly the direct contact with the material

- The production plants of anti-wear materials are found all over the country, so that it is better to take the nearest, or increase the freight and increase the cost. It's not realistic to buy things at a low price. Where are you, the specific manufacturer can search on the Internet.

- Q: The development of material handling

- The material handling equipment manufacturing industry provides various kinds of modern transportation equipment for the national economy, major construction projects and national defense security. Basic formed a comprehensive product range, good technical system and large enterprise groups, become an independent industry, machinery industry in the service of national economy in all walks of life, including for the second and the third industry provides a huge number, a great variety of products, can independently or with foreign cooperation for national key project to provide large lifting transportation machinery and complete sets of equipment system, and have a certain amount of exports. In 2011, there were 1,580 enterprises in the manufacturing industry of material handling equipment in China (RMB 20 million), and more than 400 000 employees. The industry realized sales revenue of 4723.47 billion yuan, with an industrial output value of 4712.23 billion yuan, with a total profit of 34.50 billion yuan, with an average annual compound growth rate of over 20%. With the expanding of the scale of production, improve degree of automation, material handling equipment manufacturing industry is more and more widely used in the process of modern production, function more and more big.

- Q: What is the material handling and handling equipment?

- . Highway transportation equipment Heavy tractor semi-trailer | van | | equipment | special transportation vehicle 9. Warehouse peripheral devices cllimbing trolley | slide machine loading and unloading platform | | | industrial door platform loading and unloading of rain loose 10. | | tray container unit equipment container bags | container net | slide 11. Forklift handling vehicle | electric flat car | | tractor attachments of ft | forklift parts 12. Manual handling equipment Hydraulic pallet truck cart hydraulic pallet stacker | | | lever type hydraulic lifting flat wagon | push car 13. Automatic sorting system, automatic sorting machine | | automatic sorting conveyor system automatic control systems and equipment

- Q: Urgent, please go to logistics expert, the question about the warehouse

- Buy a forklift truck with a solid price. You'd better consult with the company that makes the shelf and forklift

- Q: What is the relevant content of the flow of materials, storage and usage

- Unitized packaging and standardization is the foundation of the enterprise logistics work, for the protection of the components, the follow-up of logistics planning and the determination of through put play a key role. Adopt the reasonable unitized equipment, can reduce the invalid labor (such as inversion, not fall to the ground) in the process of machining, improve labor efficiency, simplify the site management, reduce the security hidden danger. The idea of packaging unitization and standardization is controlled mainly from macro and micro level. On the macro level, we need to set the size chain for all materials from the perspective of the supply chain. From the tray to the turntable, the special frame should be coupled with this dimension chain. On the micro level. In order to meet the basic requirements of packaging design, such as the principle of protecting spare parts and saving space, choose the proper packaging materials, internal separation materials and so on. At the same time, the loading number of the packaging unit should be fixed so as to reduce the statistical workload of the on-site staff. Some factories have higher management requirements for packaging and line workstations, which require the packaging to be incorporated into the day-to-day management of the process. For packaging, cleaning, cleaning (cleaning oil, labeling, etc.), repair, storage, etc.

- Q: What is the carrying equipment of the container cargo

- Container (container), crane, forklift truck Kunshan city peng a lift lifting transportation and handling professional clean room equipment installation, precision air handling import and export container, unpacking, assembling positioning, whole factory move, special lifting engineering contracting, precision machine packed in wooden cases

- Q: There are three things to do when the material is stacked up and down

- Fire proof, waterproof and center of gravity

- Q: What are the requirements for the science of loading and unloading

- Use material handling activities to improve control of production, inventory and order processing. Use the transport equipment to improve the production capacity. The cost of moving the unit to determine the performance of the transport. Provide appropriate means and equipment to enhance the handling safety.

Send your message to us

Portland® N-TGD belt bucket elevator for tower compound fertilizer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 99 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords