Apricus Evacuated Tube Solar Collectors - Polyurethane Foaming Insulation Model SC-HP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

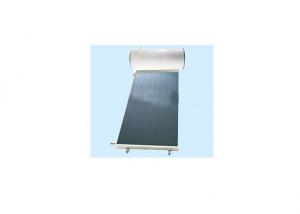

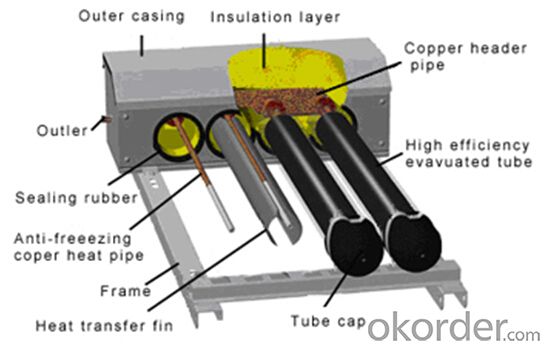

1. Structure of Polyurethane Foaming Insulation Solar Collector Model SC-HP:

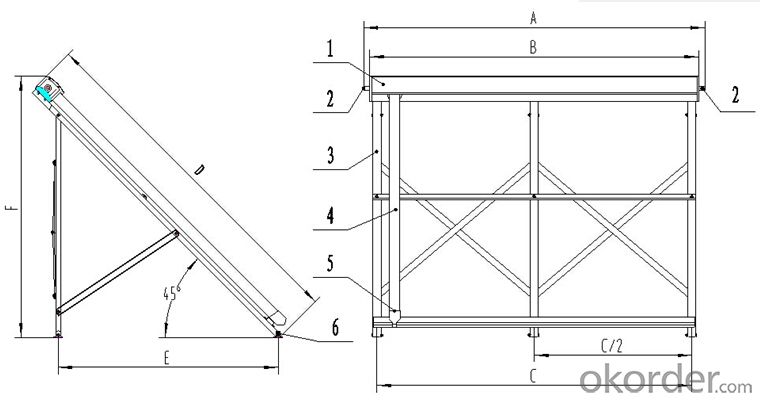

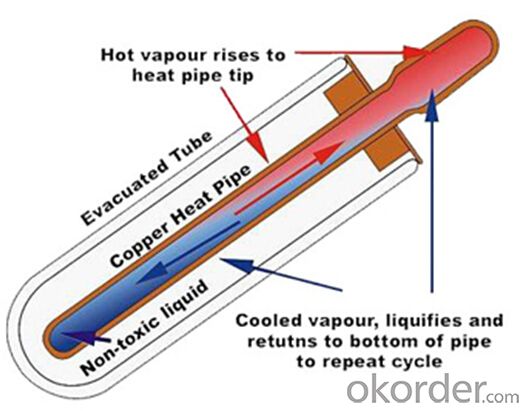

This product is composed of aluminium alloy for frame, polyurethane and aluminium silicate for the insulation,tri-element vacuum glass tube and antifreeze heat pipe. It can work under the environmental temperature from -40℃ to 95℃.The solar collector has the structure as follows:

1,Solar collector manifold :

2,Solar collector connector

3,Solar collector bracket

4,All glass vacuum tube:

5,Tube holder

6,Wind feet

2. Main Features of Polyurethane Foaming Insulation Solar Collector Model SC-HP:

The heat insulation properties is higher than for other types of the same collector design

Three layers of insulation incorporated in the mainfold casing :

(1)first and third layer is Aluminium Silicate and resist temperatures of up to 800℃;

(2)second layer is Polyurethane formed by Italian machine that insulates the tanks with a density of 38.5-42;

3. Polyurethane Foaming Insulation Solar Collector Model SC-HP Images:

4. Polyurethane Foaming Insulation Solar Collector Model SC-HP Specifications

Model | SC-HP-10 | SC-HP-15 | SC-HP-18 | SC-HP-20 | SC-HP-24 | SC-HP-25 | SC-HP-30 |

SC-H1-10 | SC-H1-15 | SC-H1-18 | SC-H1-20 | SC-H1-24 | SC-H1-25 | SC-H1-30 | |

Vacuum tube quantity(pcs) | 10 | 15 | 18 | 20 | 24 | 25 | 30 |

Tube spacing (㎜) | 75 | 75 | 75 | 75 | 75 | 75 | 75 |

Vacuum tube diameter/length (㎜) | φ58/1700 | φ58/1700 | φ58/1700 | φ58/1700 | φ58/1700 | φ58/1700 | φ58/1700 |

Vacuum tube material | high borosilicate glass 3.3 | high borosilicate glass 3.3 | high borosilicate glass 3.3 | high borosilicate glass 3.3 | high borosilicate glass 3.3 | high borosilicate glass 3.3 | high borosilicate glass 3.3 |

Vacuum tube inner/outer pipe wall thickness (㎜) | 1.6/1.8 | 1.6/1.8 | 1.6/1.8 | 1.6/1.8 | 1.6/1.8 | 1.6/1.8 | 1.6/1.8 |

Heat pipe condensing end diameter/length (㎜) | φ14/1750 | φ14/1750 | φ14/1750 | φ14/1750 | φ14/1750 | φ14/1750 | φ14/1750 |

heat pipe material/wall thickness (㎜) | Copper tp2/0.6 | Copper tp2/0.6 | Copper tp2/0.6 | Copper tp2/0.6 | Copper tp2/0.6 | Copper tp2/0.6 | Copper tp2/0.6 |

inner tank diameter/wall thickness (㎜) | φ35/1.0 | φ35/1.0 | φ35/1.0 | φ35/1.0 | φ35/1.0 | φ35/1.0 | φ35/1.0 |

connector size | φ22 or 3/4″ | φ22or 3/4″ | φ22or 3/4″ | φ22or 3/4″ | φ22or 3/4″ | φ22or 3/4″ | φ22or 3/4″ |

collector insulation material/thickness (㎜) | Polyurethane/40 | Polyurethane/40 | Polyurethane/40 | Polyurethane40 | Polyurethane40 | Polyurethane/40 | Polyurethane/40 |

solar collector rated pressure (MPa) | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

collector operating temperature ℃ | <100 | <100 | <100 | <100 | <100 | <100 | <100 |

collector volume (L) | 0.69 | 0.98 | 1.15 | 1.27 | 1.50 | 1.56 | 1.85 |

collector aperture area (㎡) | 1.0 | 1.5 | 1.8 | 2.0 | 2.4 | 2.5 | 3.0 |

collector total area (㎡) | 1.56 | 2.30 | 2.74 | 3.04 | 3.63 | 3.77 | 4.51 |

referral traffic (L/min) | 0.75 | 1.13 | 1.35 | 1.50 | 1.81 | 1.88 | 2.26 |

intensity pressure (Pa) | 23.2 | 59.2 | 90.6 | 116.7 | 181.7 | 200.2 | 314.0 |

intercept efficient η0 | 0.744 | 0.744 | 0.744 | 0.744 | 0.744 | 0.744 | 0.744 |

heat loss coefficient a | 2.09 | 2.09 | 2.09 | 2.09 | 2.09 | 2.09 | 2.09 |

collector power (W)1000W/㎡ irradiation | 620 | 870 | 1047 | 1165 | 1401 | 1457 | 1748 |

collector net weight (kg) | 38.25 | 50.75 | 59.75 | 64.75 | 79.00 | 83.35 | 98.70 |

a (㎜) | 895 | 1270 | 1495 | 1645 | 1945 | 2020 | 1395 |

b (㎜) | 800 | 1175 | 1400 | 1550 | 1850 | 1925 | 2300 |

c (㎜) | 725 | 1100 | 1325 | 1475 | 1775 | 1850 | 2225 |

c/2 (㎜) | —— | —— | —— | —— | 887.5 | 925 | 1112.5 |

d (㎜) | 1980 | 1980 | 1980 | 1980 | 1980 | 1980 | 1980 |

e (㎜) | 1240 | 1240 | 1240 | 1240 | 1240 | 1240 | 1240 |

f (㎜) | 1470 | 1470 | 1470 | 1470 | 1470 | 1470 | 1470 |

5. FAQ

(1) Which collector is the best value for money?

Rather than looking at just peak efficiency levels when comparing solar collectors, cost per unit of energy produced is much more logical. For example: Although collector A may be 20% more efficient than collector B, if collector A is 30% more expensive, then in fact collector B may be a better choice, as per kWh of energy produced per day it is cheaper. When payback time is of concern, not only price per kWh of the product is important, but also of the end system.

(2) Can this solar collectors be used for a large scale hot water production?

Yes. This solar collectors can be connected in series or parallel to provide large scale hot water production for a commercial settings such as a school, hotel or office building. There is really no limit to the size of the system, however collectors must be installed in banks of no more than 150 tubes (in series), otherwise the water may boil.

(3) What maintenance of the solar collector is required?

Under normal circumstances no maintenance of the system is required. Due to the shape of the tubes regular rainfall and wind should keep the tubes clean. Should a tube even be broken it should be replaced. This, however, is an inexpensive and easy job. Any "handy" person can install a new tube (while adhering to local health and safety regulations). Sidite solar collectors can operate with several broken tubes, however the efficiency will be reduced slightly.

- Q: How do solar collectors contribute to reducing water consumption?

- Water consumption can be reduced through the use of solar collectors, which offer an alternative and more sustainable approach to heating water. Unlike traditional methods that rely on fossil fuels or electricity, solar collectors use the sun's energy, eliminating the need for water-intensive procedures like extraction, processing, and generation. The functioning of solar collectors involves absorbing sunlight, converting it into heat, and then transferring that heat to the water in the system. This process doesn't require any additional water, making it a water-efficient choice for water heating. By employing solar collectors, water consumption is minimized as there is no need for water in electricity generation or fossil fuel extraction and processing. Furthermore, solar collectors can contribute to reduced water consumption through the use of a closed-loop system. In this system, the water in the collector circulates through pipes, getting heated by the sun, and then returning to a storage tank. This allows for the reuse of the same water, further reducing the necessity for fresh water. Additionally, the closed-loop system helps minimize the risk of contamination since the water remains contained within the system and is not exposed to external pollutants. In conclusion, solar collectors play a vital role in reducing water consumption by offering an environmentally friendly and sustainable approach to heating water. By relying on the sun's energy, they eliminate the water-intensive processes associated with traditional water heating systems, ultimately aiding in the conservation of water resources.

- Q: Are there any disadvantages to using solar collectors?

- Yes, there are a few disadvantages to using solar collectors. Firstly, the initial cost of installing solar collectors can be quite high, making it less affordable for some individuals or businesses. Additionally, the efficiency of solar collectors can be affected by factors such as weather conditions and location, resulting in fluctuations in energy production. Lastly, solar collectors require adequate space for installation, which can be a limitation in urban areas with limited roof or ground space.

- Q: Can solar collectors be used for generating electricity on smartwatches?

- Generating electricity on smartwatches using solar collectors is possible, but there are challenges and limitations to consider. The small size of smartwatches makes it difficult to harness a significant amount of solar energy. The limited surface area available for solar collectors makes it challenging to generate enough electricity to power the device effectively. Furthermore, smartwatches are typically worn on the wrist, which means they may not always be exposed to direct sunlight. This further reduces the effectiveness of solar collectors in consistently generating electricity. However, there have been advancements in solar cell technology specifically designed for small, portable devices like smartwatches. These solar cells are more efficient in capturing sunlight, even in low light conditions. They can be integrated into the display or strap of the watch. Some smartwatches already incorporate small solar panels to supplement the battery life, although traditional charging methods remain the primary source of power. While solar collectors on smartwatches may not be the sole power source, they can help extend battery life and reduce reliance on external charging. This is especially useful in situations where access to charging outlets is limited, such as during outdoor activities or travel. In conclusion, solar collectors can be used to generate electricity on smartwatches, but their effectiveness is currently constrained by the small size and limited exposure to sunlight. However, advancements in solar cell technology may lead to more efficient and practical solutions in the future.

- Q: Can solar collectors be used for heating construction sites?

- Yes, solar collectors can be used for heating construction sites. Solar thermal collectors can capture and convert sunlight into heat energy, which can then be utilized for heating purposes in construction sites. This eco-friendly and cost-effective solution can help reduce reliance on traditional heating methods and promote sustainable practices in the construction industry.

- Q: What is the impact of altitude on the performance of solar collectors?

- The impact of altitude on the performance of solar collectors is significant. Altitude affects the performance of solar collectors primarily due to two factors: atmospheric pressure and temperature. At higher altitudes, the atmospheric pressure is lower compared to lower altitudes. This lower pressure affects the boiling point of water, which in turn affects the performance of solar thermal collectors. Solar thermal collectors utilize the sun's energy to heat a working fluid, usually water or a heat transfer fluid. At higher altitudes, the boiling point of water is lower, meaning that the working fluid may reach its boiling point at a lower temperature. This can result in reduced efficiency and performance of solar thermal collectors as the working fluid may prematurely boil and lose its ability to transfer heat effectively. Additionally, altitude affects the temperature of the surrounding air. Higher altitudes generally have colder temperatures compared to lower altitudes. This can impact the performance of solar photovoltaic (PV) collectors, which convert sunlight directly into electricity. Solar PV panels operate more efficiently at lower temperatures, and the colder air at higher altitudes can help dissipate heat more effectively, leading to improved performance. However, it's worth noting that the impact of altitude on solar collector performance can vary depending on the specific design and technology used. Different types of solar collectors may have different optimal operating conditions, and altitudes can affect each type differently. Therefore, it is crucial to consider the specific characteristics and requirements of the solar collectors being used when assessing the impact of altitude on their performance. In conclusion, altitude has a significant impact on the performance of solar collectors. Lower atmospheric pressure and colder temperatures at higher altitudes can affect the efficiency and optimal operating conditions of solar thermal and photovoltaic collectors. Understanding these effects is essential when designing and implementing solar energy systems at different altitudes to ensure optimal performance and energy production.

- Q: Can solar collectors work in cloudy weather?

- Yes, solar collectors can still work in cloudy weather, although their efficiency may be reduced. Even on overcast days, solar collectors can still absorb sunlight and convert it into usable energy. However, the amount of energy produced will be lower compared to sunny days when there is more direct sunlight available.

- Q: Are solar collectors easy to install?

- Yes, solar collectors are generally easy to install. They can be installed on rooftops or mounted on the ground with minimal effort. With proper instructions and basic knowledge of electrical connections, most homeowners or professionals can successfully install solar collectors.

- Q: How much space is needed for a solar collector system?

- The amount of space needed for a solar collector system can vary depending on several factors. The size of the system will depend on the energy needs of the property and the efficiency of the solar panels being used. For residential solar collector systems, the average size can range from 100 to 400 square feet. This is typically enough to generate sufficient electricity for a typical household. However, larger properties or those with higher energy demands may require larger systems. In commercial or industrial settings, the space required for a solar collector system can be significantly larger. The size of the system will be determined by the energy consumption of the facility and the available space for installation. It is not uncommon for commercial solar systems to cover several thousand square feet or even acres of land. Additionally, the orientation and tilt of the solar panels can affect the space requirements. Ideally, solar panels should be installed facing south or southwest, with a tilt angle that maximizes the amount of sunlight they receive. This may require additional space for optimal positioning. It is important to note that while space is a consideration, solar collector systems can be designed to fit a variety of locations. Rooftop installations are a popular choice for residential systems as they utilize existing space without requiring additional land. Ground-mounted systems can be installed in open areas or unused land, making them suitable for larger systems. Ultimately, the amount of space needed for a solar collector system will depend on the specific energy needs, efficiency of the panels, and available space for installation. Consulting with a solar professional can provide a more accurate assessment of the space requirements for a specific project.

- Q: What materials are commonly used in solar collectors?

- Commonly used materials in solar collectors include glass, metal, plastic, and various types of absorber materials such as copper, aluminum, or stainless steel.

- Q: Can solar collectors be used for heating car manufacturing plants and assembly lines?

- Certainly, solar collectors can be utilized to heat car manufacturing plants and assembly lines. By harnessing the sun's energy and converting it into heat, solar thermal collectors offer a versatile solution for heating industrial facilities. Implementing solar collectors on the rooftops or open areas of car manufacturing plants allows for the effective utilization of collected solar energy to complement or replace conventional heating systems. Solar thermal collectors operate by absorbing sunlight through tubes or panels containing a heat-absorbing medium, such as water or a heat-transfer fluid. This absorbed heat can then be transferred to various heating systems, such as radiators, underfloor heating, or even the facility's ventilation system. This process ensures a comfortable working environment for employees and fulfills the heating requirements of assembly lines. Furthermore, solar collectors can be integrated with other energy-efficient technologies, like heat pumps or thermal storage systems, to optimize the usage of solar energy. These additional systems store excess heat during sunny periods and release it when needed, guaranteeing a continuous supply of heating energy even on cloudy days or at night. The utilization of solar collectors for heating car manufacturing plants and assembly lines offers several advantages. Firstly, it reduces dependence on fossil fuels and helps mitigate the environmental impact associated with greenhouse gas emissions. Secondly, it leads to considerable cost savings on energy bills, as sunlight is a free and abundant source of energy. Additionally, the integration of solar collectors into manufacturing facilities enhances their sustainability profile and contributes to the organization's overall corporate social responsibility efforts. However, it is essential to consider various factors, including geographical location, available installation space, and energy requirements of the facility, to determine the feasibility of using solar collectors for heating car manufacturing plants and assembly lines. A comprehensive assessment and feasibility study should be conducted to establish the optimal design, size, and integration of solar thermal systems to meet the specific heating needs of each manufacturing plant or assembly line.

Send your message to us

Apricus Evacuated Tube Solar Collectors - Polyurethane Foaming Insulation Model SC-HP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords