Voltex Bentonite Geotextile - Polyester/Polypropylene Short Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Polyester/Polypropylene Short Nonwoven Geotextile:

Short nonwoven geotextile made up of fibers of polyester or polypropylene in random directions and punched together by needles during the manufacturing process.Geotextiles are commenly used to separate layers like clay and drainage and to protect liner from damage.

Main Features of Polyester/Polypropylene Short Nonwoven Geotextile:

1.Engineered to provide high strength and high elongation at break to ensure excellent resistance to damage during construction.

2.Manufactured from high tenacity UV stabilised virgin polypropylene or polyester fibers which have been heavily drawn to ensure excellent long term durability in all soil types.

3.Manufactured using a randomly orientated web to provide completely isotropic properties,ensuring that high strength is not limited to a single direction.

4.Excellent uniformity with high permeability and low pore size for soil filtration.

5.Supplied to a maximum width of 6.5mts,ensuring minimum waste over large construction areas.

6.100% polypropylene or polyester staple fibers ,needle punched and random network formation.

7.UV and rot resistant and biological degradation resistant.

Specifications of Polyester/Polypropylene Short Nonwoven Geotextile:

Item | Index | ||||||

20-15 | 30-22 | 40-28 | 50-35 | 60-42 | 80-56 | 100-70 | |

Breaking strength at warp direction (kN/m) ≥ | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

Breaking strength at weft direction (kN/m) ≥ | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

Elongation at break (%) ≤ | 28 | ||||||

Trapezoid tearing strength( warp direction ) (kN) ≥ | 0.3 | 0.45 | 0.5 | 0.6 | 0.75 | 1.0 | 1.2 |

Bursting strength (kN) ≥ | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.0 | 7.5 |

Vertical permeability coefficient (cm/s) | 10-1~10-4 | ||||||

Effective pore size O95,mm | 0.08~0.5 | ||||||

Mass per unit area (g/m2) | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

Mass error in unit area (%) | ±10 | ±10 | ±10 | ±10 | ±10 | ±10 | ±10 |

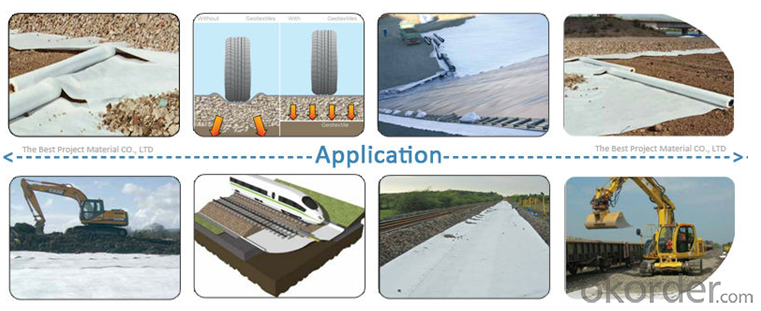

Applications of Polyester/Polypropylene Short Nonwoven Geotextile:

While the nonwoven fabric can be used in almost any stabilization,separation or cushioning application,they are most commonly used in areas that also require filatration.The non woven design of the material provides a higher rate of flow through,making it easier for water to pass through the material.

Some commen uses of the material includes the following:

1.Road stabilization applications

2.Roofs

3.Civil applications

4.Railway work

5.Landfill lining

6.Trenches

7.Dams

8.Fitration under rip rap and rocks

9.Environmental applications

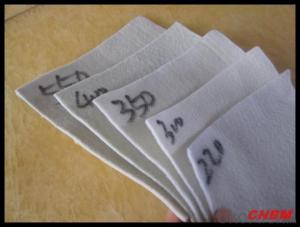

IMages of Polyester/Polypropylene Short Nonwoven Geotextile:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: How do geotextiles contribute to soil separation?

- Geotextiles contribute to soil separation by acting as a physical barrier that prevents the mixing of different soil layers. They are designed to allow water to pass through while retaining the soil particles, thus maintaining the integrity and stability of the soil layers. Additionally, geotextiles reduce the potential for erosion, improve drainage, and enhance the overall performance and longevity of structures built on or with soil.

- Q: Can geotextiles be used in geosynthetic reinforced walls?

- Yes, geotextiles can be used in geosynthetic reinforced walls. Geotextiles are commonly used as a separation and filtration layer in geosynthetic reinforced walls to prevent soil erosion, improve drainage, and provide stability to the structure.

- Q: What are the different geotextile filtration testing methods?

- There are several different geotextile filtration testing methods, including the gradient ratio test, the constant head test, the falling head test, and the sand column test. These tests are conducted to evaluate the ability of geotextiles to filter out fine particles from water or other fluids, and to assess their performance in various filtration applications.

- Q: Artificial lake geotextile practices

- Library and slope with a composite geomembrane all laying, I specialize in the production and construction of geotextile materials

- Q: How do geotextiles help with load support in unpaved roads?

- Geotextiles provide load support in unpaved roads by distributing the load from vehicles more evenly across the road surface, preventing the formation of ruts and reducing the amount of settlement. They also help in stabilizing the subgrade by acting as a separation layer between the subgrade soil and the overlying base material, preventing the mixing and migration of fine particles. Additionally, geotextiles improve the overall strength and stability of the road by enhancing its resistance to deformation and improving its load-carrying capacity.

- Q: Geotextile and geogrid difference

- Different geotextile used to prevent seepage, geogrid used to reinforce the geotextile is mainly used to seepage, isolation, geogrid are generally used in reinforced reinforcement, the two are essential differences in the use of the process Sometimes used in the same project, such as high-speed, railway and other engineering production grid is made of polypropylene, polyvinyl chloride and other polymer polymer by thermoplastic or molded two-dimensional grid or a certain height of the three-dimensional Dimensional grid grid, when used as a civil engineering, known as geogrid. Engineering applications: roads, railways, abutments, approach roads, docks, dams, slag and other soft soil foundation reinforcement, retaining walls and road surface cracking engineering and other fields. Fiberglass mesh used in the external walls, wall paint, the main material to prevent the junction of different mortar and other plastering material cracking, hollowing. Local node reinforcement will also be used. Geotextile has excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance. Common non-woven fabrics, water layer inside the use, polyethylene polypropylene waterproof also used.

- Q: Can geotextiles be used in soil erosion control on construction sites?

- Yes, geotextiles can be used in soil erosion control on construction sites. Geotextiles are permeable fabrics that can be placed on the soil surface to prevent erosion by stabilizing the soil and allowing water to pass through while retaining sediment. They are commonly used in construction sites to protect exposed soils from rainfall and runoff, reducing erosion and promoting vegetation growth.

- Q: How do geotextiles help with soil confinement in erosion control mats?

- Geotextiles help with soil confinement in erosion control mats by acting as a barrier that prevents soil particles from being washed away by water or wind. The geotextiles stabilize the soil by providing a physical barrier that holds the soil in place, reducing erosion and promoting vegetation growth.

- Q: How to apply the geotextile of the retaining wall filter

- Our manufacturer, a professional construction team

- Q: How do geotextiles help with moisture management in construction projects?

- Geotextiles aid in moisture management in construction projects by acting as a barrier against water infiltration and promoting drainage. They are permeable fabrics that allow water to flow through, preventing water buildup and potential damage to structures. Geotextiles also help to stabilize soil, control erosion, and separate different soil layers, further enhancing moisture management in construction projects.

Send your message to us

Voltex Bentonite Geotextile - Polyester/Polypropylene Short Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords