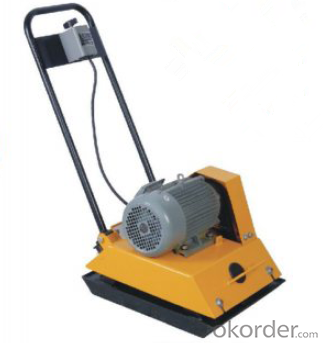

Plate Compactor HZR80-C

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Used for compacting the gravel,soil, asphalt roads, sidewalks, Bridges, car parks, sports venues and the narrow site compaction work. It’s an ideal equipment for highway, municipal departments to build roads, streets, squares.

Easy operation, flexible steering and good welt performance, good shock absorption performance.

Main Product Features:

1. Foldable handle for easy transportation and stock;(straight hand is also available)

2. Open plate provide self cleaning;

3. Radius base plate for easy access to corners;

4. Throttle control for easy holding working speed;(throttle control is optional)

5. Heavy-duty shock mounts reduce vibration to the upper engine and handle;

6. Rubber & canvas mat for brick paving compaction as option.

Product Specifications:

Model: HZR80-C

Engine: Single cylinder, air-cooled, 4 cycles.

Engine Type: Electric Type

Power: 3.0KW

Size of Base Plate: 44cm x 40cm

Centrifugal Face: 13KN

Vibration Frequency: 5500VPM

Compaction Depth: 25cm

Forward Speed: 20-25m/min

Compaction Area: 450m2/h

Climbing Ability:0-30°

Weight: 80Kg

Dimention:67cm x 45cm x 75cm

FAQ:

Q1: Does the Plate Compactor use electricity or diesel?

A1: The Plate Compactor is equipped with famous brand diesel engine.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 20 workdays.

Q4: If we can produce some Plate Compactor according to customers request?

A4: Yes, we can produce Plate Compactor according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: The front wheel of a road roller is known to be cylindrical, with a width of 2.5 meters and a diameter of 1.2 meters. The front wheel rotates 8 minutes per minute. The 1. roller takes 20 minutes from one end of the road to the other. How many meters is the length of the road?. 2. what is the area of the road roller from one end to the other end of the road?. Process and description

- 1, turn 8 laps per minute, 20 minutes, a total of =20*8=160 circles;2, because the diameter is 1.2 meters, so a turn is equal to the front wheel perimeter =3.14*1.2=3.768 (meters);

- Q: In the process of asphalt pavement construction, can the wheel roller use diesel oil to clean the surface of the wheel?

- Generally, the use of steel roller, use plain water cooling and surface cleaning, the use of rubber tire roller, the use of diesel oil, it is only in the beginning or sticking wheel rolling, rolling wheel, after a while, the surface temperature, there is no need for.In the rolling, mainly by spraying some solvents make the wheels not sticky asphalt mixture, like diesel, oil film of asphalt mixture is damaged, and the cost is high, the construction unit and the use of rapeseed oil, water washing powder, the specification also mentioned some. In general construction, more diesel and water ratio of 1:1 solution is used.

- Q: Is there eighty tons of vibration in the vibration of the eighteen ton roller?

- The domestic users generally add its weight on the equipment vibration equipment that is not scientific.

- Q: The difference between tracked roller and wheel roller

- Heavy duty rollers include horizontal vibratory rollers, which have their own weight plus vibration force to make the road more solid and flat, suitable for large road laying.

- Q: How do the rollers see dual vibration, single vibration, double drive, single drive, double steel single steel?

- Single steel wheel vibration: a steel wheel, two rubber wheelsDouble shock generally no rubber wheels, all steel wheelThere is no rubber wheels are mainly used to distinguish, more intuitiveThe main difference between single drive and double drive is on the steel wheel in front. There is only one pump on the single drive steel wheel,Both driven steel wheels have pumps on both sides

- Q: What's the difference between the German BMW roller and the German BMW? Which is better? Thank you for your advice

- In fact, according to the professional view, of course is BMW company's roller better ah, imports of domestic no better than ah, who knows what to import some excellent ah, besides a lot of domestic things are not qualified, imported things would not have said, they say BMW strict testing roller is imported from Germany so, the presence of parts are imported from Germany, BMW company products are sold in the world first, quality first, reputation first good, if the eye know what people know, want to do a big business, the first machine must choose the best, of course, is also the BMW company pulling machine.

- Q: How about a Luoyang road roller?

- Recommended to buy well-known trademarks, such as mountain push, Xugong roller, quality and after-sales service better.

- Q: BMW roller, wrong wheel, will affect the straight line?

- The roller should completely withdraw from the rolling operation period after vibration and stop slowly to avoid the wrong wrong wheel, wheel over a cause of asphalt mixture passes and squeeze the mixture.

- Q: Why is the price difference so large? Is there a problem of repeated calculation?

- 2 according to the quota of work content, only in the original soil roadbed rolled or compacted backfill roadbed with good artificial leveling roller.

- Q: Brief introduction of tyre roller

- The compacted asphalt mixture conforms to the requirements of compactness and smoothnessSelect reasonable roller combination method and rolling steps to achieve the best results. The asphalt mixture is compacted by a steel cylinder type static roller and a tire roller or a vibratory roller. The number of rollers is determined according to the production site.The compaction of asphalt mixture is carried out in three stages: initial pressure, compound pressure and final pressure (including molding). The roller is rolled at a slow and uniform speed.The initial pressure of asphalt mixture meets the following requirementsThe initial A. pressure roller soosai eng DD-110 in mixture paving after high temperature, and shall not have any time, hair crack, compaction temperature according to the consistency of asphalt, roller type, temperature paving layer thickness, mixture type is determined by the pressure test with test.B. roller is rolled from the outside to the center. The adjacent rolling zone should overlap with 1/3 - 1/2 wheel width. At last, the center part of the rolling road will be compressed at full amplitude. When the edge of the baffle, kerb, shoulder and other files, should be close to the file roller. When the edge without retaining, can mix the edge rake rake slightly high, then the outer wheel roller rolling out 10cm above the edge.

Send your message to us

Plate Compactor HZR80-C

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords