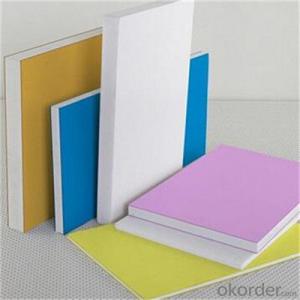

Plastic Sheets - PVC Foam Sheet for Kitchen or Furniture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

Name | Density(g/cm3)±0.02 | width and length(mm) | Thickness(mm)±0.2 | Color |

PVC Foam Board | 0.8 | 1220*2440 | 1~25 | white,red, yellow, blue, green, gray, black |

0.6 | 2~25 | |||

0.5 | 2~25 | |||

0.8 | 1560*3050 | 1~10 | ||

0.6 | 2~10 | |||

0.7 | 2050*3050 | 1~10 | ||

pvc rigid sheet | 1.36-1.45 | 1220*2440 | 0.23-1.8 | |

2-5.8 |

Features:

1. feather light, non-absorb water, fire retardant and self-extinguishing

2. sound insulation, heat insulation , noise absorption, heat preservation and corrosion preventin.

3. weather proof, vandal proof, and can be shaped, moulded, painted and screen printed.

4. non-warping and stain proof.

5. non-corrosive, non-toxic and chemical resistant.

6. tough, rigid with a high impact stregth.

7. easy to clean and maintain.

Application:

1.Advertisement: exhibition & display,digital printing,silk screen printing,engraving materials,sign board, etc.

2.Furnitureoffice furniture,cabinet,bath cabinet,etc.

3.Finishing Materialdecorative sheets,storage racks,room segments,etc.

4.Industrial Application:thermoforming products,refrigeratory warehouse project,environmental protection.

Purpose:

PVC foam can be Advertising solvent printing ,display plate ,silk-screen, computer lettering, sign plate , lightbox ,inner & out decorating panel ,commercial decorating shelf ,room separating panel roof decorating panel and other industry

Advantage: Light rough high intensity heat preservation & insulation ,damp &water proof Anti-mildew& rot , acid & alkali endurable ,sound insulation & absorbing insulated Apyrous damping aging prevention .Hot moulding and fabricated with other PVC material are available. Well fit sticked printing design pressed , paint and other fabrication.

FAQ:

Q: What's the PVC Foam Sheet Features?

A: 1, light weight,good tenacity, high rigidity

2, fireproof and flame retardant

3, good insulation

4, no sopping, no deformation

5, easily to processed

6, good plasticity, being an excellent thermoform material

7, sub-light surface and elegant vision

8, anti-chemical corrosion

9, suitable to silk screen printing

10, with imported dyes, unfading and anti-aging

Q: What's the PVC Foam Sheet Processing performance?

A: 1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

Q: How many colors you have?

A: We have more than 100 existed colors. We can send the color swatch if you leave your message. Also customized colors are acceptable.

Picture of Our Products:

- Q: Are plastic sheets resistant to breakage from impact?

- Yes, plastic sheets are generally resistant to breakage from impact. However, the level of resistance may vary depending on the type and thickness of the plastic sheet.

- Q: Ok i have a large entertainment center that was custom built and one of my 2 young girls has damaged the existing plastic mesh inserts that go inside the bottom doors. They are thin black plastic about 2 foot by 2 foot each, with many little holes (like a mesh) for the sound of the speakers to come through. I have looked all over the web for a simular material but havent had any luck finding anything. I dont care if i have to buy raw material that i have to paint or cut. I would just like to know if anyone knows where to find a material like this?

- in a home store, there's a product at the 'window screen' area.... it's called pet screen... it's black plastic mesh.... I use it in my pond, too!....all kinds of uses!!... besides screen, that is.... works good that way, too!

- Q: i'm in ireland and don't know where to buy it

- Any large DIY store, or farmers in your area may have spare from baling time. Thinking on it , won't you get it at Woodies?

- Q: I have an 08 Hyperlite Era board that has a big problem. the top plastic sheet is peeling off at the edges and it is dragging in the water bad. i dont want to buy a new board but i cant fix it. I have already tried a permanent epoxy-resin but it was destroyed after the first use. I am now thinking of shrink wrapping a resin type plastic onto the whole edge but i dont know what i am doing. Does anybody have any suggestions?

- Try going back to epoxy and try again. This time prep the surfaces by sanding with a fairly fine sand paper, and make sure all surfaces are dry. If you attempt to epoxy to either a too smooth surface, a water wetted surface or a surface that has another wax or adhesive on it the epoxy won't adhere properly. Clean and sand the surfaces first and the epoxy should be stronger than new. Good luck with your repair..

- Q: What are the advantages of LCD TVs, metal and plastic backplanes?

- The LCD panel itself has a metal backing. As for the back of the TV set, it is only a shell, what backboard is used, which has no influence on the television picture. Just look different, in fact, the TV at home, no one will care about his back. Pick TV, there is no need to select the backplane, attention should be focused on the quality, function and other technical indicators.

- Q: Are plastic sheets resistant to chemicals in swimming pool environments?

- Yes, plastic sheets are generally resistant to chemicals in swimming pool environments. They are commonly made from materials such as polyethylene or PVC, which have excellent chemical resistance properties. These plastics can withstand exposure to chlorine, bromine, and other pool chemicals without significantly degrading or corroding. However, it is important to note that prolonged exposure to certain harsh chemicals or extreme temperatures may still cause some deterioration or discoloration over time.

- Q: Are plastic sheets suitable for marine applications?

- Yes, plastic sheets are suitable for marine applications. They are often used in the marine industry for various purposes such as boat windows, hatches, windshields, and even hull construction. Plastic sheets offer excellent resistance to water, UV radiation, and corrosion, making them a reliable choice for marine environments. Additionally, they are lightweight, durable, and cost-effective, making them a popular option for marine applications.

- Q: Are plastic sheets safe for food contact?

- Plastic sheets can be safe for food contact, but it depends on the specific type of plastic being used. Some plastics, such as those labeled as food-grade or FDA-approved, are designed to be safe for food contact. These plastics are typically free from harmful chemicals and additives that could leach into the food. However, it is important to ensure that the plastic sheets are used in accordance with their intended purpose and guidelines provided by the manufacturer to maintain food safety.

- Q: Are plastic sheets resistant to discoloration from chemicals?

- Yes, plastic sheets are generally resistant to discoloration from chemicals.

- Q: Can plastic sheets be used for electrical circuit boards?

- No, plastic sheets cannot be used for electrical circuit boards. Circuit boards require materials with high electrical conductivity and heat resistance, such as fiberglass or epoxy resin, to ensure proper functioning and safety.

Send your message to us

Plastic Sheets - PVC Foam Sheet for Kitchen or Furniture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords