Geogrids Husker Plastic Net False Roof Biaxial Plastic Protect-Support Net for Coal Mine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 88 m²

- Supply Capability:

- 1800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Plastic net False roof for coal mine description :

Made of polypropylene and fire restardant additive by anti-static technology , it can bear high tensile strength .This material has considerable tensile strength in longitudinal and lateral directions. This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforce.

Features of Plastic net False roof for coal mine:

Homogenous structure, low creepage ,anti-aging and resisting acid and alkaline.

Inflaming retarding , anti static ,long lifetime,high safety factor ,high bearing capacity

Application of of Plastic net False roof for coal mine :

Make reinforce treatment for various of soft soil foundation to evenly distribute load stress and reduce unevensettlement , it is easy to wash coal . used in highway ,railway,port,airport, municipacl and projects of supporting in the recovery working face of coal mined and ladeway in the coal mine .

Specification of of Plastic net False roof for coal mine

Width : 1M,2M,3M,4M.

Length: 50m,100,

Color: black

Packaging & Delivery of of Plastic net False roof for coal mine: Each roll is wrapped in a woven bag then into container Or Packed as customers' requests.

Production periods of of Plastic net False roof for coal mine : within 10 days after receiving the deposit

Introduction of CNBM

China National Building Materials (Group) Corporation (CNBM) is a state-owned enterprise in charge of administrative affairs in China building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of RMB 25 billion and a total staff of 30,000. Now CNBM owns more than 200 subsidiaries in and abroad the country, including wholly-owned corporations and joint ventures.

FAQ of geosynthetics :

What is geosynthetics ?

Geosynthetics form a perfect erosion control fabric used extremely widely in civil engineering to stabilize and reinforce slopes and soil under or next to roads, railways, dams, water reservoirs etc.. They can be easily applied which minimizes the time of construction, as well as they limit the resources and materials necessary.

What kinds of geosynthetics we have ?

Non-woven geotextile, geogrids, geocells, GCL, Geomembranes, Geonets, Geocomposites etc .

What is the geosynthetics used for ?

Hydraulic

Lagooning and Water Treatment, Ornamental Ponds, Golf Courses

Aquaculture and Desalination,Water Lagoons,Tanks, Reservoirs, Liquid Waste,Floating Cover Solutions, Drainage and Filtration

Environment

Tailing ponds, Leach mining,Landfills,Landfill Capping,Protection against corrosion,Vertical Barriers

Civil Works

Erosion Control,Secondary Containment,Tunnels,Linear and Surface Works,Consolidation of Margins,Soil Reinforcement,Soil Separation.

Building - Parkings,Roofing,Soundproofing

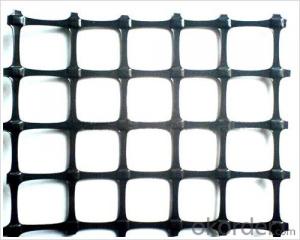

Structure of Steel-plastic Geogrid with Convex node for mine description :

Made of steel-plastic straps with arabesquitic on the surface , it can bear high tensile strength .This material has considerable tensile strength in longitudinal and lateral directions. This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforce.

Features of Steel-plastic Geogrid with Convex node for mine:

Homogenous structure, low creepage ,anti-aging and resisting acid and alkaline.

Application of Steel-plastic Geogrid with Convex node for mine :

Make reinforce treatment for various of soft soil foundation to evenly distribute load stress and reduce unevensettlement , it is easy to wash coal . used in highway ,railway,port,airport, municipacl and projects of supporting in the recovery working face of coal mined and ladeway in the coal mine .

Specification of Steel-plastic Geogrid with Convex node for mine

TGSG15-15,TGSG20-20,TGSG25-25,TGSG30-30,TGSG35-35,TGSG40-40,BP15-15MS,HPP20-20MS, HBPP25-25MS,HBPP30-30MS,HBPP35-35MS,HBPP40-40MS

Width : 1M,2M,3M,4M.

Length: 50m,100,

Color: black

Packaging & Delivery of Steel-plastic Geogrid with Convex node for mine: Each roll is wrapped in a woven bag then into container Or Packed as customers' requests.

Production periods of Steel-plastic Geogrid with Convex node for mine : within 10 days after receiving the deposit

- Q: Can geogrids be used in reinforcement of dams and levees?

- Yes, geogrids can be used in the reinforcement of dams and levees. Geogrids are commonly used in civil engineering projects to enhance the stability and strength of soil structures. When applied in dams and levees, geogrids help to distribute loads, prevent soil erosion, and increase overall stability, thereby improving the structural integrity of these crucial water management systems.

- Q: What are the installation methods for geogrids?

- There are several installation methods for geogrids, including direct placement, mechanical connection, and soil confinement. Direct placement involves laying the geogrid directly on the ground and securing it with stakes or pins. Mechanical connection involves connecting the geogrid to other materials, such as retaining walls or slopes, using connectors or anchor systems. Soil confinement involves placing the geogrid within a layer of soil to improve its stability and strength. The specific installation method used depends on the specific project requirements and conditions.

- Q: What is the recommended geogrid aperture shape for specific applications?

- The recommended geogrid aperture shape for specific applications depends on various factors such as soil type, project requirements, and installation method. It is essential to consult with geotechnical engineers or geosynthetic specialists who can analyze the specific project needs and recommend the most suitable geogrid aperture shape, which can range from square to rectangular or triangular.

- Q: How do geogrids improve the performance of geotextile sediment control tubes?

- Geogrids improve the performance of geotextile sediment control tubes by providing additional structural support and reinforcement. They help to prevent the tubes from collapsing or deforming under the weight of sediment, enhancing their overall stability and effectiveness in controlling erosion and sediment runoff.

- Q: Geogrid is divided into several?

- Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid.

- Q: How do geogrids help stabilize soil?

- Geogrids help stabilize soil by providing reinforcement and increasing the overall strength of the soil. They are typically made of high-strength materials such as polyester or polypropylene, and are placed within the soil to distribute loads and limit movement. This prevents soil erosion, improves slope stability, and enhances the bearing capacity of the soil, thus effectively stabilizing it.

- Q: Are geogrids effective in preventing soil erosion around pipelines?

- Yes, geogrids are effective in preventing soil erosion around pipelines. Geogrids are engineered materials that provide reinforcement and stabilization to the surrounding soil. They create a barrier that helps prevent soil movement and erosion caused by water flow or other environmental factors. Geogrids also distribute the weight and stress of the pipeline more evenly, reducing the chance of soil settlement and potential damage. Overall, geogrids play a crucial role in protecting pipelines from soil erosion and ensuring their long-term stability.

- Q: Are geogrids suitable for use in mining tailings ponds?

- Yes, geogrids are suitable for use in mining tailings ponds. Geogrids provide excellent reinforcement and stabilization properties, helping to prevent soil erosion and maintain the structural integrity of the tailings pond. Additionally, geogrids are durable and resistant to chemicals and harsh environmental conditions, making them an ideal solution for containing and managing mining waste in tailings ponds.

- Q: What are the advantages of using geogrids in ground improvement for slope stabilization?

- There are several advantages of using geogrids in ground improvement for slope stabilization. Firstly, geogrids provide reinforcement to the soil, increasing its strength and stability. This helps to prevent slope failures and landslides. Secondly, geogrids help to distribute the load more evenly across the slope, reducing the stress on the soil. This can improve the overall performance and longevity of the slope stabilization system. Additionally, geogrids are easy to install and cost-effective compared to other methods of slope stabilization. They can be used in a variety of soil conditions and are resistant to degradation from environmental factors. Overall, geogrids offer a reliable and efficient solution for slope stabilization, reducing the risks associated with unstable slopes.

- Q: What kind of geogrid can meet the requirements

- Polypropylene single pull plastic grille TGDG80 meet the requirements

Send your message to us

Geogrids Husker Plastic Net False Roof Biaxial Plastic Protect-Support Net for Coal Mine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 88 m²

- Supply Capability:

- 1800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords