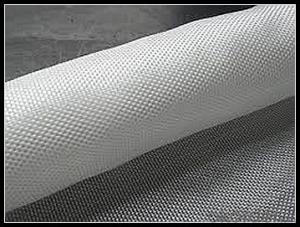

Geotextil Tejido Y No Tejido Pet Nonwoven High-Performance Construction Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Geo Textiles

Geotech segment comprises of technical textile products used in Geotechnical applications

pertaining to soil, rock, earth etc.

This class of product is loosely called Geotextiles.

However Geotextiles particularly refers to permeable fabric or synthetic material, woven

or non-woven, which can be used with geotechnical engineering material.

Woven and Non Woven Geotextiles are robust and durable fabrics designed to increase soil

stabilization and ground support in a given location. Typically made from polypropylene

fibers, these geotextiles are high in strength to allow for maximum slope support,

stabilization and erosion control. Options include a felt-like nonwoven material as well

as a woven polypropylene blend.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in road construction?

- Yes, geotextiles can be used in road construction. They are commonly used as a stabilization measure to reinforce the soil, control erosion, and enhance the overall performance of the road. Geotextiles help in distributing the load evenly, improving drainage, and preventing the intermixing of different soil layers. Additionally, they can also provide a barrier to prevent the intrusion of fine particles into the road base.

- Q: Can geotextile skin be connected?

- Geotextile skin can be touched. Geotextile production of raw materials is polyester fiber, polyester has been widely used in daily life. Such as clothes are also a lot of polyester material. So do not worry, geotextile is not harmful to the human body.

- Q: Geotextile what is the law?

- Geotextile, also known as geotextile, it is made of synthetic fiber through acupuncture or woven from the permeability of geosynthetics. The American Society of Agricultural Engineers defines geotextiles as geotextiles or geosynthetics that exist between soils and pipelines, gages, or retaining walls that enhance water movement and impede soil movement. ASTM 4439 standard geotextile is defined as: a purely permeable geosynthetics to form textiles. Is used in soil, rock, soil or other geotechnical engineering related materials and acts as a component of a human-made project. Geotextile is a new type of building materials, raw materials are polyester, polypropylene, acrylic, nylon and other polymer polymer synthetic fiber. In accordance with the manufacturing method is divided into: there are two types of geotextile and non-woven geotextile. General engineering is mainly used non-woven geotextile. Geotextile with filter, filter, isolation, reinforcement, protection, sealing and other functions.

- Q: How do geotextiles help in groundwater drainage?

- Geotextiles help in groundwater drainage by acting as a filter and separator between the soil and the water. They allow water to pass through while preventing the migration of fine particles, thus preventing clogging of drainage systems. Additionally, geotextiles help in distributing the flow of water evenly, reducing the chances of localized flooding and promoting efficient groundwater drainage.

- Q: Can geotextiles be used in the construction of landfills?

- Yes, geotextiles can be used in the construction of landfills. Geotextiles serve as a barrier to prevent the mixing of different types of soil layers, provide separation between different materials, and enhance the stability and strength of the landfill structure. They also help in controlling erosion and drainage within the landfill site.

- Q: Geotextile standard is broken how low?

- You can not do it

- Q: I would like to make the beach bigger along the lake in our backyard. I am hoping to do it myself for my husband for father's day. I need suggestions on the best way to do this as a one women team.

- Geotextile Landscape Fabric

- Q: 3923.1 why not apply to geotextiles

- Geotextile price, geomembrane price, composite geomembrane price can be found tgcl1123 to see

- Q: How are geotextiles different from other types of geosynthetics?

- Geotextiles are a type of geosynthetic that are specifically designed to provide filtration, separation, and reinforcement functions in civil engineering applications. Unlike other types of geosynthetics such as geogrids or geomembranes, geotextiles are typically made from non-woven or woven fabrics, allowing them to have a higher permeability and flexibility. Geotextiles are primarily used to control soil erosion, improve drainage, and provide stability in various construction projects.

- Q: Geotechnical deployment of aging detection of what indicators

- Geotextile aging test: anti - ultraviolet ability. That is, at a certain temperature, the sun under the strong changes in geotextile.

Send your message to us

Geotextil Tejido Y No Tejido Pet Nonwoven High-Performance Construction Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords