PE gas pipe manufacture P302

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

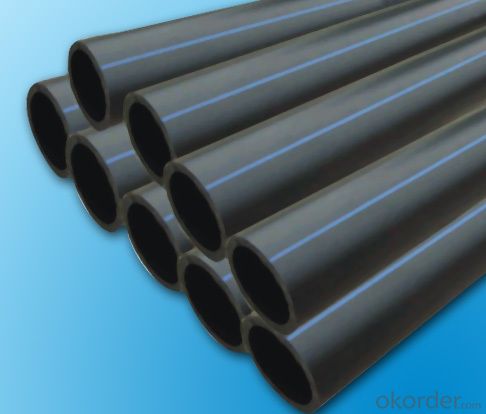

1. PE gas pipe manufacture (GB/T 15558-2003)

Quick Details

· Place of Origin: China (Mainland)

· Material: PE

· Specification: 20-630mm

· Length: 5.9/11.8M

· Standard: GB/T15558-2003

Packaging & Delivery

Packaging Details: | bundle or as your required |

Delivery Detail: | within 15 days after downpayment |

Specifications

PE gas pipe manufacture (GB/T 15558-2003)

1. OD:20-630mm

2. Standard: GB/T15558-2003

3. Quality with competitive price

PE GAS PIPE

Material: PE 100

Specification: 20mm-630mm

Length: 5.8m 11.8m per length

Thickness: 2.3mm~57.3mm

Standard: GB/15558, ISO4437

Color: black, yellow or black with yellow stripe or others

Feature:

**Long service life: PE pipe can be used safety for more than 50 years

**Excellent resistance to corrosion capability: It can endure the erosion of various kinds of chemical media, no electrochemical corrosion.

**Excellent transportation capability: the inner side of the PE pipe is smooth and has litter abrasion and resistance. The absolute roughness k=1.01mm and “k” will not change with time.

**Reliable joint capability: the intensity of the welded joint of PE pipes is above the pipe itself. The interface will not disconnect because of the moving of soil or the live load.

**Reliable safety capability: PE pipe has strong capability of anti-cracking and is not prone to crack.

**Better resistance to concussion capability: PE pipe possesses high toughness and can endure strong impact. Pressure of heavy things will not cause the pipe to break.

**Strong toughness: PE pipe is a kind of pipe that possesses high toughness whose breaking elongation rate generally exceeds 500% and has strong ability to adapt to the uneven settlement of the pipe bending.

**Excellent flexibility: PE pipe can be easy to change in accordance with the construction requirements. Small-diameter pipe is available to be supplied in coils.

**Installation cost lower: light weight, easy handling and installing, simple welding technique and exemption of being embalmed result in low construction cost.

Application:

gas distribution, environmental protection, and chemical industry etc.

2. PE PIPE MANUFACTURE (ISO 4427)

Quick Details

· Type: Other Plastic Building Materials

· Place of Origin: China (Mainland)

· Size: 16-1600mm

· Color: Black, blue

Packaging & Delivery

Packaging Details: | plastic bags or as your request |

Delivery Detail: | Within 25 days after receiving the payment |

Specifications

PE PIPE MANUFACTURE (ISO 4427)

A. Material: High quality PE80 or PE100

B. Diameter: 16 to 1600mm

C. Pressure:0.6-1.6Mpa

PE PIPE MANUFACTURE (ISO 4427)

Features:

**Sizes: 16 to 1600mm

**Pressure Rating: 0.6MPa, 0.8MPa, 1.0MPa, 1.25MPa, 1.6MPa

**Colors: blue, black or other colors on request

**Connection: socket fusion joint, butt fusion joint, electro fusion joint, flanged joint

**Standard: GB/T 13663, ISO 4427

**Certification: ISO9001, ISO14001

**Packaging: coils in plastic bag or as your request

Advantages:

**Non-toxic: no heavy metal additives, would not be covered with dirt or contaminated by bacterium

**Corrosion Resistant: resist chemical matters or electron chemical corrosion

**Lower Installation Costs: light weight and ease of installation can reduce installation costs by

as much as 50% over metal piping system

**Higher Flow Capacity: smooth interior walls result in lower pressure loss and higher volume

than metal pipe

**Longevity: more than 50 years under proper use

**Recycled and Environment-friendly

Application

water pipe network system, industrial liquids transportation, Agricultural irrigation pipe and sewage treatment

- Q: What glue can glue rubber tube?

- Location: in the face and then drop a little sticky rubber JL-330 iron speedglue, immediately bonded, and keep to the hardening, hardening time ranging from a few seconds. About 30 minutes to reach practical strength, 24 hours after the maximum intensity.

- Q: What is the function between the rubber pipe joint and the installing pipe?

- The action of the rubber pipe joint on the installation of pipes:1. Small size, light weight, good elasticity, easy installation and maintenance.2. After installation, the transverse, axial and angular displacement of the pipe vibration can be absorbed. The pipe is not concentric and the flange is not parallel.3 、 after installation, it can reduce the noise caused by vibration of pipes, pumps and so on, and has strong vibration absorption ability.

- Q: What's the difference between the rubber hose joint and the stainless steel hose joint?

- 1, high water use of this product, the pipeline must be fixed or fixed support bracket, otherwise the product should install anti pull off device. The force of fixed support or bracket must be greater than the axial force, or should install anti pull off device. And because the metal hose pressure resistance better, do not need to install.2, you can choose to use according to their working pressure: 0.25MPa, 0.6MPa, 1.0MPa pipe, 1.6MPa, 2.5MPa, 4.0MPa of the flexible rubber joint, high pressure pipeline equipment, we recommend that customers choose chungha brand stainless steel metal hose, according to the different use of the environment and the size, our biggest can withstand up to 300KG, customers can also ease of use.

- Q: Is flexible rubber joint and telescopic device a kind of thing?

- The utility model discloses a pipe expansion device, which is a connecting piece which is compensated by the size change caused by thermal expansion and cold contraction in the pipe connection. There are two kinds of pipe expander, one is rubber pipe telescopic device, and the other is metal pipe telescopic device.

- Q: What's the cause of a default like a general rubber product?

- It's aging of rubberAging refers to the polymer materials (including rubber, plastics, fiber and so on) in the processing, storage and use of the process, due to the comprehensive effect of internal and external factors, its performance gradually deteriorated, resulting in the final loss of use value.

- Q: The main features of Linatex rubber tube or what are the characteristics?

- Linard, BB:, halogenated butyl rubber. Acid and alkali resistance, good air tightness, high temperature resistance.Linaplus, FG:, natural rubber, FDA certified, for long-term exposure to food applications.Linaplus, OZ:95% natural rubber, excellent abrasion resistance, UV resistance, and ozone performance

- Q: Is the installation of submersible pumps mandatory for the installation of flexible rubber joints?

- According to the design requirements, choose whether the installation of rubber joints, Kannami Masashige water supply equipment Co., Ltd. is specializing in the production of rubber joint manufacturers, products and technical advice

- Q: The pipe of the gas water heater is buried in the wall. It is made of nylon tube and rubber tube. Is it possible to use rubber tube?

- With respect to the through wall gas safety management regulations, it is clear that hoses can not be used through walls.

- Q: What with the appropriate suction tube Dichotomanthes tube and rubber machine

- The bellows are extruded by the extruder, and the winding tubes are wound in circles

- Q: What's the difference between hose and hose for compressed air?

- When the joint is made into a quick plug, hard pipe is rare; for example, galvanized steel pipe, joint practice is similar to hydraulic tubing. The pipes in the compressed air are welded with steel tubes, but I don't think that's what you call the hard tube

Send your message to us

PE gas pipe manufacture P302

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords