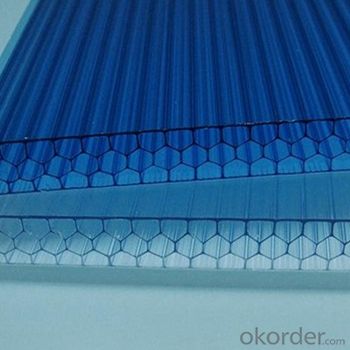

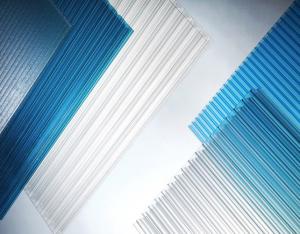

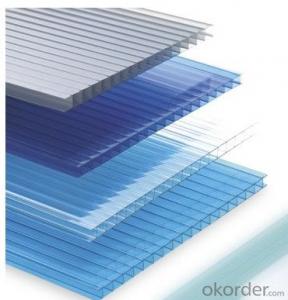

PC Hollow Polycarbonate Sheets for One Stop Gardens Greenhouse Parts

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Applications

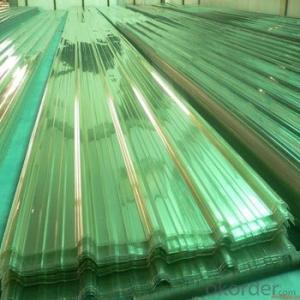

1.Roofing light sheet and sunshade for office building polystyrene foam sheet extrusion line

2.Skylight, lighting for corridors, balcony, passages and subway entries, walkways

3. awning, canopy.

4.Advertising lamp boxes, sign board, polystyrene foam sheet extrusion line

5.Anti-riot shield, bullet resistant material, Bank ATMs.

6.Conservatories, agricultural greenhouses, zoos, botanical gardens.

7..Industrial Roofing and Glazing

8..Industrial Roofing and Glazing

9.Unusual decorations, corridors

10.Interior and exterior decorations of commercial buildings

11.Interior and exterior decorations of commercial buildings

12.Telephone booths, street name plates and sign boards

13.Roofing skylight for office building, department store, hotel, stadium, school, hospital.

Features:

1) Light transmission: Up to88%

2) Impact resistance: 80 times that of glass, 15 times that of acrylic sheeting

3) Temperature resistance range: -40 ~ 120°, C

4) Light weight: Only 1/12 of the weight of glass of the same thickness

5) Ultraviolet resistance: With UV protective layer

6) Flame resistance: Rated class B1

7) Sound and heat proof

FAQ:

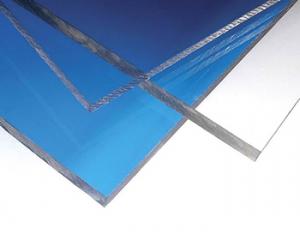

1.What are polycarbonate sheets?

Polycarbonate sheets are a transparent, synthetic product. Because of its exceptional impact, weather and temperature resistance, it provides solutions where other synthetics fail. Polycarbonate has a different chemical composition, and therefore different properties, from other transparent plastics such as PVC.

2.Can I install polycarbonate sheets myself ?

Polycarbonate sheets are particularly user-friendly and very light, so that fewer cross bars are needed.

This makes the supporting structure more straightforward and cheaper.

3. Do the sheets discolor overtime ?

Because of its transparent UV protective layer polycarbonate sheets do not discolour and most polycarbonate sheets come with a 10-year guarantee... but they can last even longer than that!

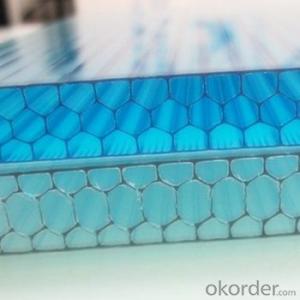

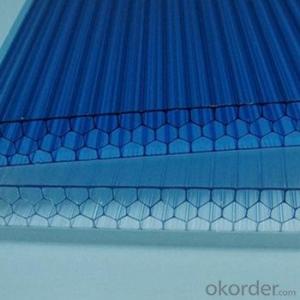

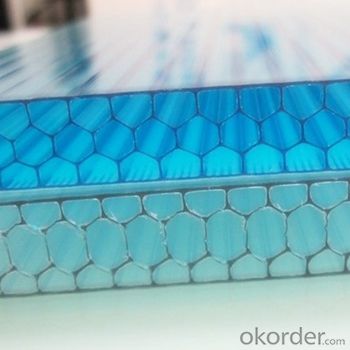

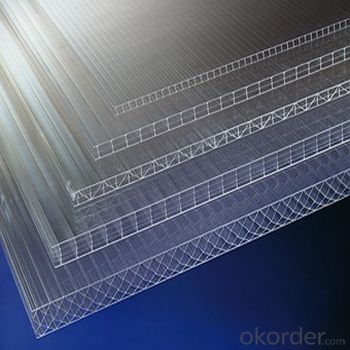

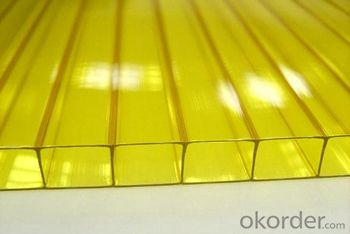

Product Pictures

- Q: PE sun panels and PC sun panels are different

- PC temperature some, much better transparency, PE is not temperature, transparency in general. PE price is about twice as low.

- Q: Sunshine board can be used in what areas

- Sunshine board with high transparency, light weight, shock, noise, heat insulation, flame retardant, anti-aging characteristics, is a high-tech, comprehensive performance is extremely remarkable, energy saving and environmental protection plastic sheet, is currently widely used in the world Plastic building materials, other architectural decoration materials (such as glass, plexiglass, etc.) can not match the advantages of widely used in greenhouse / industrial plant, decoration, advertising signs, parking shed, channel lighting poncho residential, commercial lighting sky, Ecological restaurants, sports venues, swimming pools, warehouses lighting roofs, factories, sports venues and sun shelters, greenhouses, aquaculture and flower greenhouses, as well as telephone booths, newsstand, station and other public facilities, highway noise, advertising Decoration field.

- Q: Who can tell me, plastic hollow board and PC sun board in the end what is the difference?

- Compared with the PC sun panels, it has the following advantages: The price is cheap, it's only one-third the price of a PC sunshine board. ?? Plastic hollow board for the software structure, roll packaging can be transported, saving shipping. Veneer area, the largest can be made 200m2 each (100 meters long × 2 meters wide). Easy to install greenhouse, greenhouse low cost. Long life, more than 10 years of the greenhouse is still in use.

- Q: Pc sun panels and frp lighting board what are the two differences

- Pc sun plate is a polycarbonate material hollow board used in outdoor building lighting top to achieve anti-ultraviolet, weather, anti-aging effect.

- Q: What is the difference between PC stamina and PC sunboard?

- The easiest way to do this is to compare one or more of the sun panels with the stamina. The difference is obvious, from the structural distinction, PC sun panels have a single layer, double, and even multi-layer and is hollow. PC Nai Liban is single layer solid. From the weight of the distinction, because the sun is hollow, the material is relatively small, so the same thickness and area of the endurance plate much heavier than the sun.

- Q: What is the difference between a hollow board and a sunboard?

- Sunshine board is one of the lighting board, most of the lighting board is made of FRP and the sun is made of PC (polycarbonate) made, a little PC board warranty period is 10 years and 15 years, The better FRP lighting board warranty period of 20 years, 25 years. Performance comparison, although the thermal conductivity of the lighting board than the sun board is low, but the lighting board is usually a single layer, thermal conductivity than the sun plate. That is the summer sun exposure, then, under the lighting board room temperature to be higher. Light transmittance, carrying capacity under normal circumstances 2 can meet.

- Q: PC sun panels and color steel plate how to bond

- The use of sealant at the junction, with self-tapping screws fixed on the purlins. Transparent sun panels and insulation color plates are two different roofs. The sun panels are mainly made of PC / PET / PMMA / PP. English is sunlight, referred to as hollow board, pc sun panels to polycarbonate as the main raw material manufacturing. Sunshine board in the mid-80s into the building materials quickly. Color steel plate, refers to the color coated steel plate, color coated steel plate is a kind of organic coating with steel plate. Color steel plate is divided into veneer, Caigang composite board, floor board and so on. Widely used in large public buildings, public buildings, activities board room, and integrated housing walls and roofs.

- Q: Can sunscreen be insulated at night? PC sunshine board insulation performance how?

- In addition, the thicker the thickness of the polycarbonate PC solar panels, the more layers, the better the insulation performance, but not necessarily the thicker the better, because the PC sheet with the thickness increases, structural complexity, price increases, or to Choose the right one. PC sunshine board during the day cold, night insulation, suitable for greenhouses and other greenhouse lighting insulation use, PC sun panels up to 49% insulation.

- Q: Lighting board and sunshine board which is good?

- The panels are made of fiberglass, and the sun panels are made of polycarbonate. Each have their own strengths and weaknesses, see your use. Sun panels used in building lighting, greenhouse shed shed more use. Low-grade will not say, high-end sunshine board can be used for more than a decade is no problem, manufacturers generally guarantee ten years! Sun plate is not strong acid and strong base this is true!

- Q: What is the difference between the sunboard and the Capron board?

- The difference between the sunboard and the cardboard: Sunshine board is collectively referred to as mainly produced by PC / PET / PMMA / PP material, one of which is sunshine board, also known as pc sunshine board, polycarbonate as the main raw material manufacturing. PC sun panels are commonly used in the international plastic building materials, there are other architectural materials (such as glass, plexiglass, etc.) can not match the advantages of "not broken glass," said. Widely used in greenhouse / industrial plant, decoration, advertising signs, parking shed, channel lighting rain pond residential, commercial lighting sky, exhibition lighting, sports venues, swimming pool, warehouse lighting business, factories, sports venues lighting ceiling and sun shelter, Agricultural greenhouses, aquaculture and flower greenhouses, as well as telephone booths, newsstand, station and other public facilities, highway noise, advertising decoration field.

Send your message to us

PC Hollow Polycarbonate Sheets for One Stop Gardens Greenhouse Parts

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords