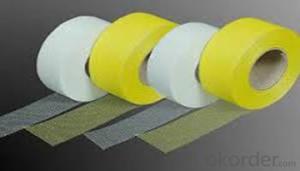

Packing Tape Fiberglass Mesh Gummed Adhesive Tape Single Side Waterproof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. product show

2.Product specification

| 1.Base Material: | BOPP Film(Biaxillary Oriented Poly Propylene Film) |

| 2.Adhesive Coating: | Emulsion Pressure Sensitive Water Base Butyl Acrylic |

| 3.Printability: | Up to 3 colors as per specifications by Rotogravure Printing. |

| 4.Peeling Strength With 180#730: | 4.5~7N/2.5CM |

| 5.180 Peel Adhesion: | 2N/CM |

3.Our advangtages

1.BOPP tape, superb tack and adhesion to surface. Strong grip that is ensured because of an excellent adhesive backing.

Quality processing equipment that guarantees consistent quality.

2.Peak performance even under extereme conditions of pressure and temperature. Sticks on all types of surfaces.(paper, plastic, wood,glass,fiber,metal,etc)

3.Consistent quality; 4.On time delivery; 5.Effective and timely communication; 6.Competitive price.

4.Company information

China National Building Material Group Corporation(CNBM), estiblished in 1984, as the largest group corporation of building materials in China. It ranked the 267th among the global FORTUNE 500 CORPORATIONS. And it's a China state-owned enterprise, ranked the 143 large-scale groups under the administration of the state-owned Assets supervision and administration commission of the state council.

With thelargest geosynthetics base about 667000m2 in China and have about 120production lines for all geo materials. For geotextile, our production capacity each day can be 300,000m2. We warmly welcome your order and visit. CNBM guarantee good quality and serivce with comptetitive prices.

5.Our service

1.OEM Service

Your own design is appreciated; we can make the approval sample according to your golden sample.

2. QC Service

a) Before the order to be confirmed, we should check the material & color of fabric by sample which should be strictly.

b) We will be tracing the different phase of production from the beginning.

c) Every bad quality will be checked & cleaned before packing.

d) Before delivery clients could send one QC or point the third party to check the quality.

e) We will try our best to help clients when problem occurred.

3. After-sale Service

a) EXW, FOB, C&F are also available for us.

b) If the products need certificate, we can also provide.

6.FAQ

Q1: May I have samples?

A: Yes, Free samples available and freight collect by DHL,FEDEX,TNT,UPS,SF,ect.

Q2: Are you manufacturer or trading company?

A: We are professional Manufacturer/factory .

Q3: Can I use our own designing?

A: Yes, size, color, printing, logo, paper core, carton box can be customized.

- Q: How do I prevent packaging tape from curling up?

- To prevent packaging tape from curling up, there are a few things you can try: 1. Use a tape dispenser: Using a tape dispenser helps keep the tape straight and prevents it from curling. It also makes it easier to cut the tape to the desired length. 2. Apply tape evenly: When applying the tape, make sure to pull it tightly and apply it evenly across the surface. Avoid any wrinkles or bubbles as they can cause the tape to curl up. 3. Clean the surface: Ensure that the surface where you are applying the tape is clean and free from any dust, dirt, or moisture. These factors can interfere with the adhesive properties of the tape, causing it to curl. 4. Store tape properly: Proper storage of packaging tape is essential to prevent it from curling. Keep it in a cool, dry place away from direct sunlight. Extreme temperature changes can affect the tape's adhesive properties and lead to curling. 5. Choose good quality tape: Invest in high-quality packaging tape that is designed for long-term adhesion. Cheaper tapes often have lower quality adhesives that are prone to curling. 6. Use a heat source: If you are experiencing curling issues with the tape, you can try using a heat source like a hairdryer on a low setting. Gently heat the tape while applying it to help activate the adhesive and reduce curling. By following these tips, you should be able to prevent packaging tape from curling up and ensure a secure and professional-looking packaging.

- Q: Does packaging tape come in different dispenser options for ease of use?

- Packaging tape is available in different dispenser options, making it easier to use. The market offers various types of dispensers that are specifically designed to simplify the process of sealing boxes or packages. These dispensers come in different sizes, styles, and functionalities to accommodate different needs and preferences. One popular type of dispenser is the handheld dispenser. It is lightweight and compact, making it easy to handle and maneuver. These dispensers usually have a serrated blade for cutting the tape and a comfortable grip for better control. They are ideal for small to medium-sized packaging tasks. For larger packaging jobs, tabletop or benchtop dispensers are available. These dispensers are designed to sit on a surface and securely hold the tape roll in place, allowing for efficient and continuous taping. They often have a built-in cutting mechanism for easy and precise tape cutting. Moreover, there are automatic or electric dispensers that offer even more convenience. With these dispensers, you can effortlessly dispense and cut the tape with the push of a button, saving time and effort. They are especially useful for high-volume or repetitive packaging needs. To summarize, different dispenser options are available for packaging tape to cater to various preferences and requirements. Whether you need a handheld dispenser for small tasks or an automatic dispenser for larger volumes, there are dispenser options that can enhance the ease of use and efficiency of your packaging process.

- Q: Can packaging tape be used for sealing cardboard boxes?

- Yes, packaging tape is commonly used for sealing cardboard boxes as it provides a strong and secure bond.

- Q: Can packaging tape be used for sealing paper bags?

- Yes, packaging tape can be used for sealing paper bags. Packaging tape is designed to have strong adhesive properties that bond well with various surfaces, including paper. When applied properly, packaging tape can provide a secure and reliable seal for paper bags, keeping the contents inside protected and preventing them from falling out or being exposed to external elements. It is important to ensure that the surface of the paper bag is clean and dry before applying the tape for optimal adhesion.

- Q: What are the considerations for using packaging tape on textured surfaces?

- There are several factors to consider when using packaging tape on textured surfaces. To begin with, the texture of the surface can impact how well the tape sticks. Textured surfaces often have uneven or rough areas that can make it challenging for the tape to securely adhere. It is crucial to select packaging tape that is specifically designed for textured surfaces. These tapes have a stronger adhesive that can better stick to uneven surfaces, ensuring that the tape remains in place. Another factor to think about is the tape's durability. Textured surfaces can be more abrasive than smooth surfaces, causing the tape to wear out more quickly. It is important to choose packaging tape made from a durable material, such as reinforced or heavy-duty tape. These types of tape are designed to withstand more wear and tear, providing a longer-lasting bond on textured surfaces. Furthermore, the texture of the surface can affect the appearance of the tape. As textured surfaces are not smooth, the tape may not lay flat and can create air pockets or wrinkles. This can give the package a messy or unprofessional look. To improve the appearance, it may be necessary to use extra tape or apply it in a way that smooths out any unevenness. Lastly, the removal of the tape from textured surfaces should be considered. Textured surfaces can make it more challenging to cleanly remove the tape without leaving behind any residue. To avoid damaging the surface or leaving sticky residue, it is recommended to test the tape on a small, inconspicuous area before fully applying it. If residue does occur, adhesive removers are available to safely remove any remaining residue. In conclusion, when using packaging tape on textured surfaces, it is important to choose tape specifically designed for uneven surfaces, select a durable tape that can withstand the texture, consider the appearance of the tape on the textured surface, and be cautious of any potential residue left behind when removing the tape.

- Q: Is packaging tape safe to use on ceramic tiles?

- Yes, packaging tape is safe to use on ceramic tiles. It adheres well to the smooth surface of the tiles and does not cause any damage or leave any residue when removed.

- Q: Can packaging tape be used for sealing construction or building materials?

- Yes, packaging tape can be used for sealing construction or building materials. While it may not be as durable or strong as specialized construction tapes, packaging tape can still provide a temporary or quick solution for sealing materials such as cardboard, plastic sheets, or lightweight panels. It can be used to secure temporary covers, attach protective layers, or hold materials in place during construction or renovation projects. However, for long-term or heavy-duty applications, it is recommended to use tapes specifically designed for construction purposes, as they are more resistant to weather, UV rays, and have stronger adhesive properties.

- Q: What are the considerations for using packaging tape on plastic or polyethylene bags?

- When using packaging tape on plastic or polyethylene bags, there are a few key considerations to keep in mind. Firstly, it is important to ensure that the tape used is compatible with the material of the bag. Plastic or polyethylene bags are typically smooth and slick, so using a tape with a strong adhesive specifically designed for such surfaces is crucial to ensure proper adhesion. Additionally, it is important to consider the strength and durability of the tape, especially if the bag will be subjected to rough handling or transportation. Opting for a tape with strong tensile strength and tear resistance will help to prevent the tape from coming loose or the bag from tearing. Lastly, considering the removal process is important, especially if the bag needs to be reopened or accessed frequently. Choosing a tape that allows for easy and residue-free removal can be beneficial in such cases. Overall, selecting the right type of tape that is compatible with the plastic or polyethylene bag, offers good strength and durability, and provides easy removal can help ensure effective and secure packaging.

- Q: Can packaging tape be used for securing cables or cords?

- Yes, packaging tape can be used for securing cables or cords. It provides a temporary solution for bundling and organizing cables, but it is not the most ideal or durable option. Using specialized cable ties or Velcro straps is recommended for a more secure and long-lasting solution.

- Q: How does packaging tape perform in high-pressure conditions?

- Packaging tape is designed to provide reliable adhesion and sealing under various conditions, including high-pressure environments. In high-pressure conditions, such as during shipping or transportation, packaging tape performs exceptionally well due to its strong adhesive properties and durable construction. The adhesive used in packaging tape is typically a pressure-sensitive adhesive (PSA), which means it adheres to surfaces when pressure is applied. This allows the tape to create a secure bond with the packaging material, even under high-pressure conditions. The tape's adhesive strength ensures that it remains firmly attached to the package, preventing any potential damage or tampering during transit. Moreover, packaging tape is often made from sturdy materials such as polypropylene or PVC, which further enhances its performance in high-pressure conditions. These materials provide excellent tensile strength, meaning they can withstand significant pressure without breaking or tearing. This ensures that the tape maintains its integrity and keeps the package sealed and protected. Additionally, packaging tape is often resistant to moisture, temperature changes, and other environmental factors that can impact its performance. This resistance helps the tape maintain its adhesive strength and structural integrity even in demanding conditions, including high-pressure environments. Overall, packaging tape is specifically engineered to perform well in high-pressure conditions. Its strong adhesive properties, durable materials, and resistance to various environmental factors make it a reliable choice for ensuring package integrity and protection during shipping or transportation.

Send your message to us

Packing Tape Fiberglass Mesh Gummed Adhesive Tape Single Side Waterproof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches