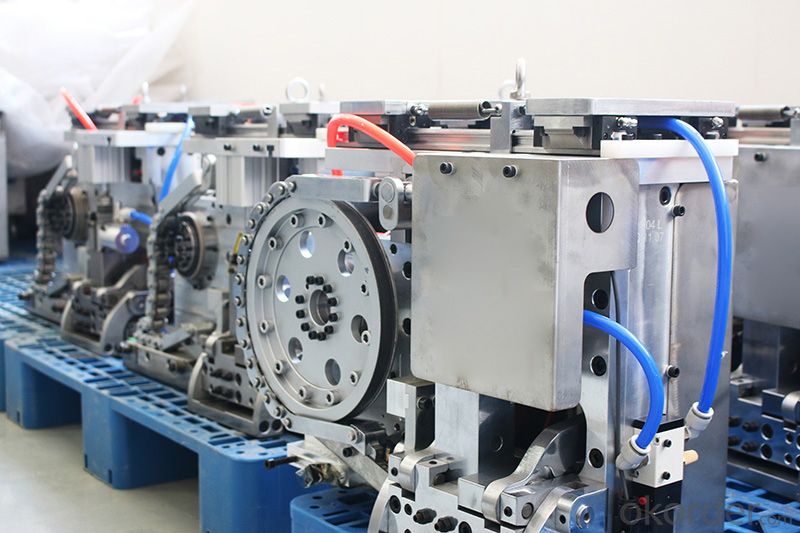

Packaging equipment---Digital intelligent baler head

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

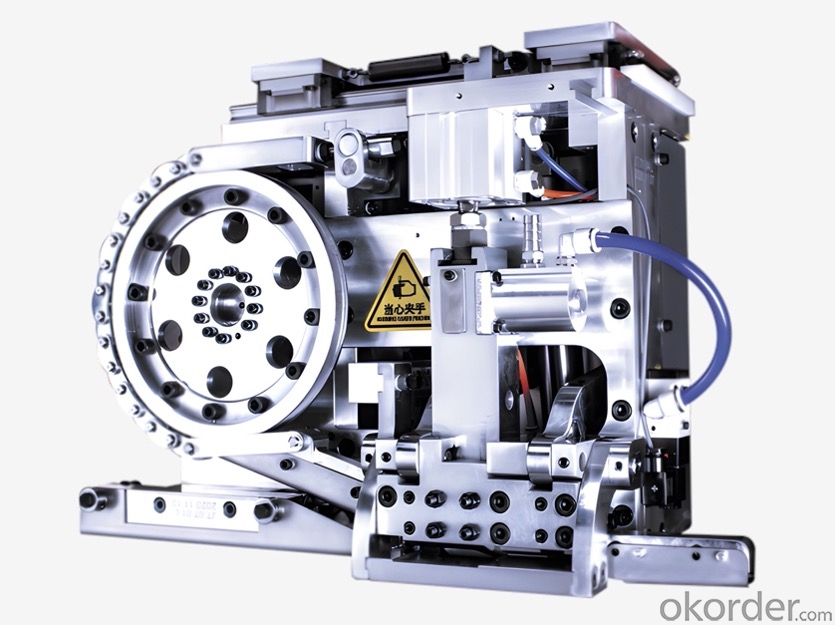

Product introduction:

The product is simple in structure, easy to maintain, and stable in performance. The tightening force can be adjusted arbitrarily by numerical control, and the maximum tightening force is 800kg.

1. Not easy to damage, low maintenance cost, remote maintenance

There are more than ten kinds of conventional wearing parts of imported machine heads. Our smart machine head has a reasonable structure and has abandoned some other redundant processes. There are only 4 conventional wearing parts, only the cutter, the friction bottom plate, and the friction machine. The head piece and the pulley, the maintenance cost is extremely low.

Adjustable tension, it can be tensioned multiple times without breaking.

2. Reasonable structure, quick maintenance, it only takes 10 minutes to replace any wearing parts

The disassembly process of the product is less than 3 minutes, and the installation of wearing parts is less than 3 minutes. The whole process only takes about 6 minutes. For other personnel, it will not exceed 10 minutes. This saves a lot of time and ensures the delivery of the project.

Finally, let's analyze the usage of this product.

1. The cost of machine head accessories can save 30,000-50,000 yuan per year.

2. Not easy to be damaged, save 30,000 yuan from belt wear and tear every year

3. The maintenance of other machine heads is delayed for a long time (1-3 hours), resulting in a decrease in output and an increase in various costs.

4.10 minutes quick maintenance without delaying production.

The overall cost saving is about 100,000 yuan a year.

- Q: What is the general packing cost of beer beverage packaging?

- Beer beverage hot shrink packaging generally use PE heat shrinkable film, packaging temperature is usually in accordance with the film material and thickness to set,

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- You can consider the promotion above the industry website.Plus, you're the packaging machine for candy and cookies, and of course it's the maker of candy and cookies.

- Q: What are the main functions of packaging machinery?

- Eight main functions of packaging machinery and equipmentPacking is a necessary condition for products to enter the circulation field

- Q: What kind of reducer is commonly used in packaging machinery?

- There are many kinds of reducers used. What kind of machines are they under?

- Q: Color code positioning of packaging machinery

- The use of the printed color packaging materials, photoelectric switch (available on the color electric eye tracking and positioning), through the control system to drive the stepper motor rotation and color according to the distance between the automatic stop, to complete and accurate packaging products logo.

- Q: What is the delay time of the packer's cross sealing?

- There is also a delay in the end of the last movement of the machine to the beginning of the sealing action.

- Q: Whether you can press paper plastic molding after PET

- Another hot pressing mould pressing needs, blister sealing machine uses a plastic bakelite mold mold, high frequency plastic welding machine is used Aluminum Alloy mold. The size of the mold needs to be determined by blister.

- Q: How does the pulp solidify? What additives do you need? Curing agents? Or what do you need as binders?

- Urea formaldehyde resin is a water-soluble resin, easily cured, the cured resin colorless, non-toxic, good light resistance, long-term use does not change color, heat molding will not change color, can add various colorants to prepare various brightly colored products.Urea formaldehyde resin is hard, scratch resistant, weak acid, weak base and grease. It is cheap and has certain toughness, but it is easy to absorb water, so it has poor water resistance and electrical properties, and its heat resistance is not highThe use of urea formaldehyde resin is widely used in plastic, mold, laminated plastic, foam, also can be used for the production of water-soluble adhesive, the adhesive for wood; fabric shrinkproof and crepe treatment agent; used as a varnish of paper, in order to improve the wet strength of paper. The following is a simple Shaoxing on it the application of the plastic.

- Q: What are the packaging machines that use temperature control watches?

- Direct heating sealing machine, blister packing machine, plastic sealing machine, heating pot, oven, toaster and so on

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Now the standard of living has improved, basically the vacuum bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

Send your message to us

Packaging equipment---Digital intelligent baler head

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.