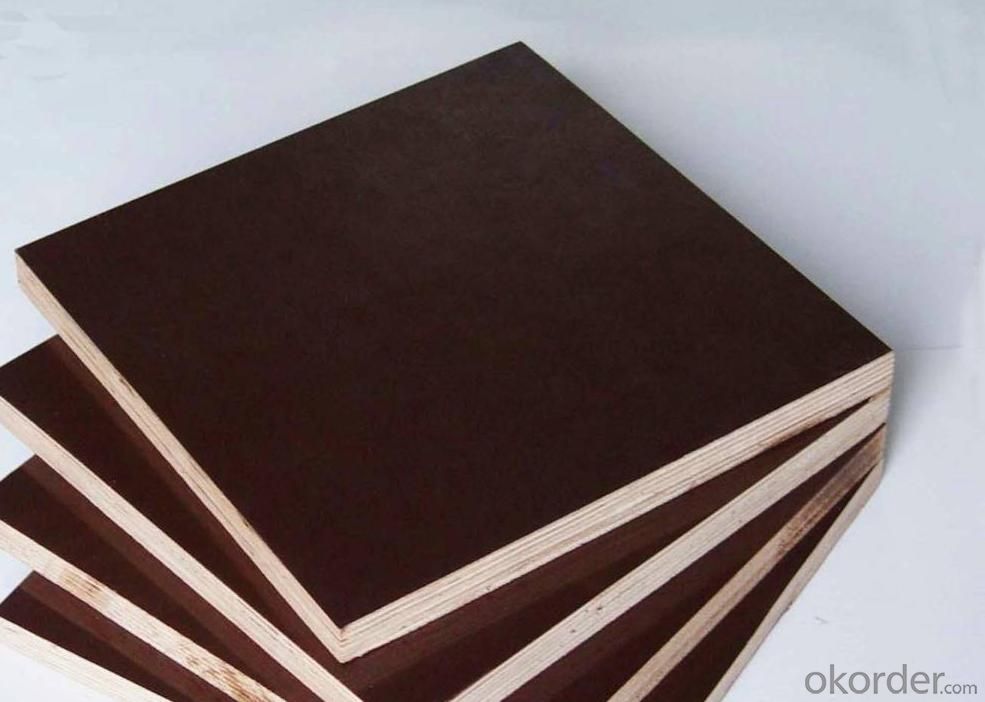

Form Plywood - Outdoor Usage 4x8 Plywood Cheap Commercial Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 59000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

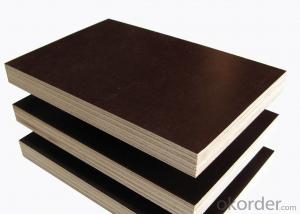

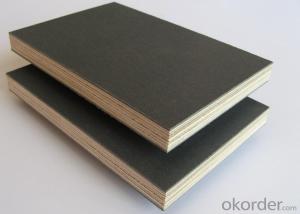

| Production Name | FILM FACED PLYWOOD/CONSMOS PLYWOOD |

| Size | 1220x2440mm(4'x8'), 1250x2500mm, 915x1830(3'x6') or as per your requirement |

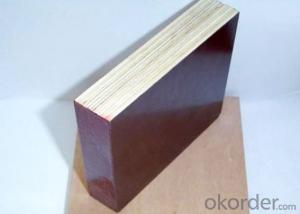

| Thickness | 8-24mm |

| Thickness Tolerance | +/-1mm - +/10.5mm |

| Number of Plies | From 5 to 15 depending on thickness |

| Face/Back | Black Film, Brown Film, Red Film (Film can be printed with requested logo) |

| Finish | Glossy, Matt, Anti-slip |

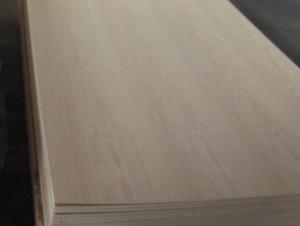

| Core | Poplar, Hardwood, Birch, Combined |

| Glue | WBP-MELAMINE, WBP-PHENOLIC, MR |

Specifications

film faced plywood

1 waterproof

2 UV capability not easily fade

3 Anti-scratch, anti-acid alkali

4 Environmentally, E1 gra

610*2500*20mm film faced plywood manufacturers,marine plywood

Specifications

1. More than 12 years production experience

2. More than 8 years export experience

3. Excellent after-sell service

1. Big Size: The biggest size is 2440*1220mm, 915*1830 mm, which could decrease the numbers of the joint and increase the working efficiency. And the planking will not deform and crack, it can resist water well, re-use many times and demoulds easily.

2. Light weight:It is more suitable for high-rise building and bridge construction.

3. Re-use number:For Melamine glue, usually can be used about 8 times, and for WBP glue, can be re-using above 15 times.

4. Concrete building: It can keep the surface smooth and beautiful when used for pouring, and you don’t need to plaster the wall for second time, for it can decorate directly that will decrease the construction period by 30%.

5. Corrosion resistance: It will not pollute the surface of the concrete.

6. Good moisture-retention: It is good for construction, and in winter it can be used as template for curved surface.

7. Good workability: It is better than bamboo plywood and small steel plywood in terms of nailing, sawing and drilling, it can be processed to template with all shapes according to needs.

Product advertage:

1.The transference to concrete is set up very easily, so good for construction work. (There is no need for any transference preparation.)

2.It is good to keep surface warm so in winter the project can also be continued.

3.After installation of concrete, the surface looks like a mirror. (The cement does not stick.)

4. The film faced plywood can be used to make camber and it also can be cut into small pieces according the special requirements.

5.Environmentally friendly.

6.It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time

- Q: What are the further processing of plywood?

- Direct printing plywood Direct print plywood is printed directly on the plywood surface with simulated wood grain or other patterns.

- Q: How do you choose plywood in plywood production?

- Another problem is the growing number of furniture produced by the panel, although these furniture, "cypress" and other grain appearance,

- Q: What plywood is now commonly used?

- Melamine gel: moisture-proof, and has a certain resistance to boiling, weather resistance / can be used for outdoor or indoor, but can not often be water immersion

- Q: What are the processing defects of plywood?

- Edge defects at the edges of the panel due to sanding, sawing or collision caused by the corner defects.

- Q: The density of the plywood is greater than that of the same kind of wood

- Plywood gluing strength, according to the Chinese national standards: Ⅰ class plywood for the 1.2 ~ 1.6 MPa, Ⅱ class 1 to 1.4 MPa, Ⅲ class 1 to 1.2 MPa, Ⅳ class 1 MPa

- Q: What are the key points for plywood selection?

- panel decoration need to use transparent varnish (also known as oil), to retain the natural color of wood surface and texture, should focus on the panel material, pattern and color selection

- Q: Classification of plywood for construction

- if you want to make general indoor wood products, you can use E1 (or even E0) urea formaldehyde

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- As these high quality woods become increasingly scarce and expensive, people begin to make furniture with easier access to wood, and those good wood is already very rare

- Q: Plywood in the processing of defects

- sand through sandlng through due to excessive sanding the table, local wear exposed layer or the next layer of veneer

- Q: Decorative veneer veneer plywood features

- The product is natural and rustic, natural and noble, can create the best and elegant living room environment

Send your message to us

Form Plywood - Outdoor Usage 4x8 Plywood Cheap Commercial Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 59000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords