Lumi Low and Medium Quality OPP Packing Tapes

- Loading Port:

- Fuzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of OPP Packing Tape

OPP packing tape are made of BOPP films coated with acrylic adhesive.

Application of OPP Packing Tape

1. Industrial box parking

2. outside electronics product packing with safety material

3. gift wrapping &decoration

4. general purpose repair

5. bundling &strapping

6. stationery purpose

Advantage of OPP Packing Tape

1.Packing tape, superb tack and adhesion to surface, Strong grip that is ensured because of an excellent adhesive backing.

2. Peak performance even under extreme conditions of pressure and temperature, which can stick to all types of surfaces.

3. Consistent quality

4. on time delivery

5. Effective and timely communication

6. Competitive price

Packing of OPP Packing Tape

individually wrapped, shrink, carton.

6rolls/shrink, about 36~100rolls/carton(according to different specifications)

carton size : any carton size as your request

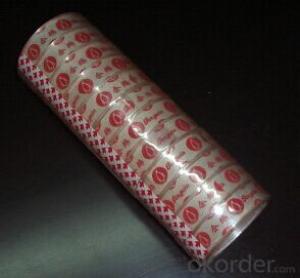

Pictures of OPP Packing Tape

Specification of OPP Packing Tape

| Material | OPP |

| Adhesive Side | Single Sided. |

| Adhesive | Acrylic, Water based acrylic adhesive |

| Acrylic | Water based acrylic adhesive |

| Color | Transparent clear/yellowish /tan brown/blue/red/ green |

| Normal thickness | 36mic, 38mic, 40mic, 43mic, 45mic, 46mic, 48mic,50mic, 52mic |

| Packaging | Single packed, shrink film packed, depend on customer’s request |

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

5.What are the international commodity codes for these products?

HS Code: 48231900.

6.Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

- Q: Can packaging tape be used for sealing construction materials or tools?

- Yes, packaging tape can be used for sealing construction materials or tools, but it may not provide as strong or durable of a seal as other specialized tapes designed specifically for construction purposes.

- Q: Can packaging tape be used for sealing plastic containers?

- Indeed, plastic containers can be securely sealed with the utilization of packaging tape. Specially designed to adhere to diverse surfaces, packaging tape effectively prevents spillage or damage to the container's contents. While commonly employed for sealing boxes in transit or storage, it can also be employed with efficacy on plastic containers. Nevertheless, it is crucial to ensure the tape is firmly affixed and all edges and seams are adequately sealed to uphold the container's integrity.

- Q: Can packaging tape be used for sealing plastic bags?

- Yes, packaging tape can be used for sealing plastic bags. Packaging tape is designed to have strong adhesive properties that can securely seal items together, including plastic bags. The tape can be applied along the opening or across the entire width of the bag to provide a tight seal and prevent contents from spilling out or being exposed to air and moisture. However, it is important to note that packaging tape may not be as effective as specialized plastic bag sealing methods, such as heat sealing or ziplock closures, which are specifically designed for this purpose.

- Q: For the moment the yellow rubber stamp [] how to use paper and pen, pen parts packaging tape?

- If the mud is in small yellow, it's better to put some tape around your fingers and wrists...

- Q: How does packaging tape differ from masking tape?

- Packaging tape differs from masking tape primarily in terms of their intended uses and adhesive properties. Packaging tape is specifically designed for sealing boxes and packages, providing a strong and durable bond that can withstand shipping and handling. It is usually made of a strong material like polypropylene and has a strong adhesive that sticks well to various surfaces, including cardboard and plastic. On the other hand, masking tape is designed for temporary applications like painting and crafting. It has a less aggressive adhesive that allows for easy removal without leaving residue or damaging surfaces. Masking tape is typically made of paper and is not as strong as packaging tape, making it unsuitable for heavy-duty tasks like sealing boxes for shipping.

- Q: Can packaging tape be used for sealing packages with medical or pharmaceutical products?

- Yes, packaging tape can be used for sealing packages containing medical or pharmaceutical products. However, it is important to ensure that the packaging tape used is of high quality and specifically designed for such sensitive products to maintain their integrity and prevent any contamination.

- Q: Is packaging tape safe for use on photos or artwork?

- Yes, packaging tape is generally safe for use on photos or artwork, but it is not the ideal choice. Packaging tape is designed for securing boxes and packages, and it may not be archival quality, meaning it may not provide long-term protection for photos or artwork. Using packaging tape on photos or artwork can potentially damage the surface or leave residue when removed. It may also yellow or discolor over time, affecting the appearance of the artwork or photo. For preserving the integrity and longevity of photos or artwork, it is recommended to use acid-free archival tape specifically designed for this purpose. Archival tape is made with materials that are safe for use on delicate surfaces, and it is designed to be easily removable without causing any damage. In conclusion, while packaging tape can be used in a pinch, it is advisable to use archival tape to ensure the best protection for your valuable photos or artwork.

- Q: Which kind of sealing tape is solvent resistant?

- Insulation properties are greatly improved with specifications (0.05mm-0.08mm) * various widths and lengths. The aluminum foil tape matches the joint of all the aluminum foil composite materials, the sealing of the puncture point of the heat preservation nail and the repair of the damaged part

- Q: What are the benefits of using easy-release packaging tape?

- The benefits of using easy-release packaging tape are numerous and can greatly simplify the packaging process. Firstly, easy-release packaging tape is designed to have a low adhesion level, which means it can be easily removed without leaving any residue or damaging the surface it was applied to. This is particularly useful when packaging delicate or valuable items, as it ensures that the tape can be removed without causing any damage. Furthermore, easy-release packaging tape is also time-saving. It can be quickly applied and removed, which increases efficiency and saves valuable time for individuals or businesses that frequently package and ship items. The ease of use also reduces the chances of mishaps or errors during the packaging process, resulting in a smoother and more streamlined experience. Additionally, the ease of release offered by this type of tape makes it more environmentally friendly. Since it can be easily removed without leaving any sticky residue, it reduces the need for excessive cleaning or scraping, which can be time-consuming and may require the use of harmful chemicals. This not only benefits the environment but also reduces costs associated with cleaning supplies and labor. Lastly, easy-release packaging tape offers versatility. It can be used for a wide range of applications, including sealing boxes, securing packages, or bundling items together. The tape is often available in different sizes and materials, allowing users to choose the most suitable option for their specific needs. Overall, the benefits of using easy-release packaging tape include easy removal without residue or damage, time-saving properties, environmental friendliness, and versatility. These advantages make it an excellent choice for anyone looking to simplify their packaging process and ensure a hassle-free experience.

- Q: Is packaging tape safe to use on painted surfaces?

- Yes, packaging tape is generally safe to use on painted surfaces. However, it is recommended to test a small, inconspicuous area first to ensure that the tape does not damage or peel off the paint.

Send your message to us

Lumi Low and Medium Quality OPP Packing Tapes

- Loading Port:

- Fuzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches