Black Woven High-Performance Geotextile Fabric for Railway - CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

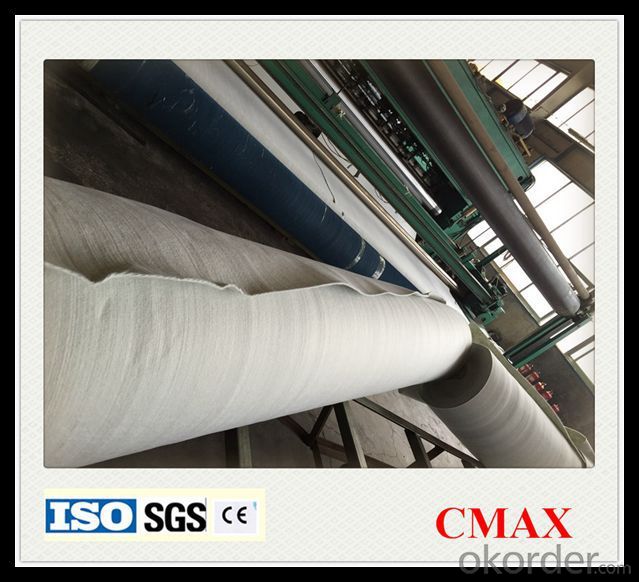

Non-woven (Filtration and Drainage Fabrics)

Needlepunched polypropylene fiber geotextiles utilized in site drainage, blanket drains

and pipe joint wrapping and erosion control under rip rap.

As a Separator is utilized amid the inappropriate and out of place material and good bag

filled with material, this practice will further help decrease the excavation deepness of

unsuitable or inappropriate sub-grade. It minimizes the cumulative width to even out and

alleviate the sub-grade. The non woven geo textile fabric preserves a consistent

settlement of the sub-grade and for this reason helps enhances the sub grade potency and

extends the working life of the system.

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Is the case, we detect the company now want to engage in expansion (that is, increase the test items), the need for material to do qualification certification. But I have not done before, do not know their own data done unreasonable. Take the data mainly for reference, know the approximate range of the various parameters. Question added: it is best to have data logging source and derivation formula to support the reasonableness of this result, thank you! More

- Hello, can only help you this, do not know useful to you useless factory production geotextile geomembrane drainage board

- Q: Would like to know the product of the market

- According to geotextile specifications to offer. Ranging from $ 1-9.60.

- Q: What are the applications of geotextiles in civil engineering?

- Geotextiles have various applications in civil engineering, including soil stabilization, erosion control, filtration, drainage, and reinforcement. They are commonly used in road construction, retaining walls, embankments, and landfills to improve the performance and durability of these structures. Geotextiles offer benefits such as increased load-bearing capacity, enhanced drainage, and reduced soil erosion, making them essential components in many civil engineering projects.

- Q: Can geotextiles be used in foundations and retaining walls?

- Yes, geotextiles can be used in foundations and retaining walls. Geotextiles are often used as a separation and filtration layer between the soil and the foundation or retaining wall materials. They can enhance the stability and durability of these structures by preventing soil erosion, improving drainage, and reducing the risk of soil contamination.

- Q: Can geotextiles be used in mine tailings dam construction?

- Yes, geotextiles can be used in mine tailings dam construction. Geotextiles are commonly used as a geosynthetic material in various civil engineering applications, including dam construction. In the case of mine tailings dam construction, geotextiles can provide reinforcement, filtration, and drainage properties to enhance the stability and performance of the dam. They can help prevent soil erosion, control water flow, and improve the overall integrity of the structure.

- Q: Can geotextiles be used for reinforcement of paved surfaces?

- Yes, geotextiles can be used for the reinforcement of paved surfaces. Geotextiles are commonly deployed underneath the asphalt or concrete layers of paved surfaces to enhance their strength, stability, and durability. They help distribute the load over a larger area, prevent cracking and rutting, and control the growth of vegetation. Additionally, geotextiles can minimize the potential for reflective cracking and provide separation between different layers, enhancing the overall performance of paved surfaces.

- Q: Are there any geotextiles on the upstream dam slope?

- Supply geotextile.

- Q: Are geotextiles suitable for use in geogrid reinforced soil slopes?

- Yes, geotextiles are suitable for use in geogrid reinforced soil slopes. Geotextiles provide additional reinforcement and stability to the soil, enhancing the performance of geogrids in slope stabilization. They help in preventing soil erosion, reducing water infiltration, and improving overall slope stability.

- Q: Waterproof and protective layer between which type of geotextile isolation layer

- Personally think to take impervious geotextile. Anti-seepage geotextile has excellent water permeability, filterability, durability, can be widely used in railways, highways, sports museum, dams, hydraulic construction, then hole, coastal beach, reclamation, environmental protection and other projects. Mainly staple acupuncture non-woven geotextile and split film woven geotextile. Check the original post & gt; & gt; trouble to adopt, thank you!

Send your message to us

Black Woven High-Performance Geotextile Fabric for Railway - CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords