Gravel Driveway Geotextile Fabric with Lightweight Compounding Silk - Non Woven Geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Drainage Non Woven Geotextile With Light Weight Compounding Silk

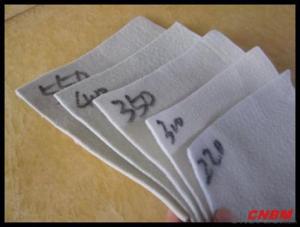

1,Specification:

(1)SNG100——SNG1500

(2)Product size:

width1m--8m, length50m---100m or at request.

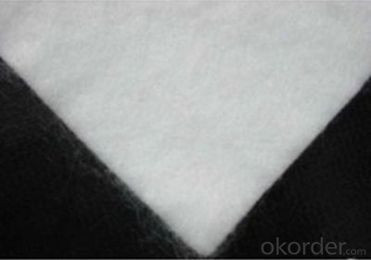

(3) color: white , black , gray, etc.

(4) geotextile material: polyester.

2.Property:

The product has the property of anti-aging, high strength, good flexibility and permeability, filtration, isolation and easy construction

3.Usage:

It is widely used in areas of the railway, highway, sport venue,dyke,water project construction, tunnel,sea beach,inning,environment protection and so on. It can also used in the reinforcement, separation,filtration,drainage ect.

Detailed Images

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in railway track bed stabilization?

- Yes, geotextiles can be used in railway track bed stabilization. Geotextiles are often used as a separation layer between the subgrade and ballast in railway track construction. They help to prevent the mixing of fine subgrade soils with the ballast, improving overall stability and drainage of the track bed. Geotextiles also provide reinforcement and enhance the load-bearing capacity of the track bed, reducing settlement and extending the lifespan of the railway infrastructure.

- Q: What is the geotextile of the asphalt pavement?

- You should be talking about concrete pavement and asphalt pavement with what geotextile bar, asphalt pavement dedicated filament singeing geotextile, is a way to enhance the road and roadbed of the new fine geotextile. It has high tensile strength, high elastic modulus, excellent resistance to high and low temperature performance, excellent acid resistance and aging resistance. In short, filament singeite geotextiles are widely used in asphalt pavement , Cement concrete pavement and roadbed enhancement

- Q: How do geotextiles help with reinforcement of geotextile tubes?

- Geotextiles help with the reinforcement of geotextile tubes by providing stability and strength. They act as a barrier, preventing soil erosion and maintaining the shape and integrity of the tube. The geotextile acts as a filter, allowing water to pass through while retaining soil particles, which helps in soil consolidation and prevents the tube from collapsing. Additionally, geotextiles distribute stress evenly across the tube, enhancing its load-bearing capacity and overall performance.

- Q: Are geotextiles suitable for high-traffic areas?

- Yes, geotextiles are suitable for high-traffic areas. They are designed to provide stability, erosion control, and reinforcement to the soil, making them an effective solution for areas with heavy foot or vehicle traffic. Geotextiles can help distribute loads and prevent soil compaction, thereby reducing maintenance requirements and extending the lifespan of the area.

- Q: The amount of geotextile drained pipe drape

- According to the two sides agreed by the measurement method, such as by the extension of the package or the expansion of the area can be calculated, you can also agreed to package a tube how much money. Generally calculated by the expansion of the area is more reasonable, because the size of the pipeline.

- Q: What are the key considerations for geotextile installation in cold climates?

- Some key considerations for geotextile installation in cold climates include selecting a geotextile that is suitable for low temperatures, ensuring proper ground preparation and compaction to prevent frost heaving, using appropriate installation techniques such as anchoring or weighting the geotextile to prevent movement, and considering the potential for snow accumulation and its effects on the geotextile's performance. Additionally, monitoring and maintenance during winter months is crucial to address any potential damage caused by freezing and thawing cycles.

- Q: Staple acupuncture non-woven geotextile is what material synthesis

- Using polyester staple fiber fineness of 6-12 denier, the length of 54-64mm polyester crimped short fiber as raw material. Polyester staple fiber is made of polyester (that is, polyethylene terephthalate, referred to as PET, from PTA and MEG polymerization) re-spinning into the fiber after cutting.

- Q: What are the specifications for geotextiles in drainage projects?

- The specifications for geotextiles in drainage projects typically include factors such as the material type, weight, permeability, tensile strength, and filtration properties. The geotextile material should be appropriate for the specific drainage application and capable of withstanding the anticipated loads and environmental conditions. It should also have a specific weight or thickness to ensure proper performance. The permeability of the geotextile is important to allow water to flow through while preventing soil particles from clogging the drainage system. Tensile strength is a crucial factor as it determines the geotextile's ability to withstand installation stresses and potential loads. Lastly, filtration properties are essential to retain soil particles while allowing water to pass through.

- Q: Geotextile drainage network and geotextile how to heat stick

- Geotextile and geotextile crimp part of the use of sewing or hot air welding. Hot air welding is the connection method of filament geotextile, that is, with the hot air gun on the connection of two pieces of cloth instantaneous high temperature heating, so that part of the molten state, and immediately use a certain external force to make it firmly together. In the case of wet (rain and snow) weather can not be hot adhesive connection, geotextile should take another method of a suture connection method, that is, with a dedicated sewing machine for two-wire suture connection, and the use of anti-chemical UV suture.

- Q: What are the primary applications of geotextiles?

- Geotextiles have various primary applications that include erosion control, soil stabilization, drainage systems, road construction, and filtration.

Send your message to us

Gravel Driveway Geotextile Fabric with Lightweight Compounding Silk - Non Woven Geotextile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords