Plastic Sheets - New PVC Foam Board for Construction from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction

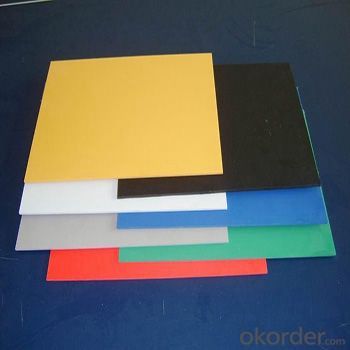

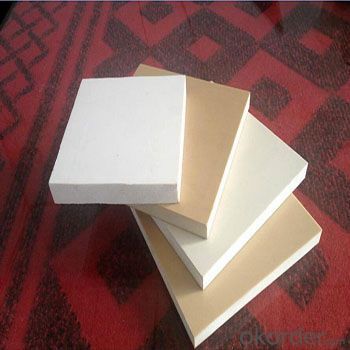

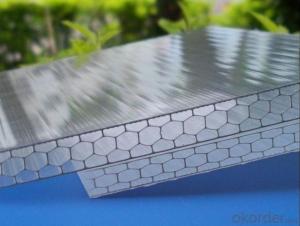

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm or as your request

Thickness:1-33mm

Production Capacity:10000pcs per month

Usage Life: more than 50 years

3.Features:

1. Waterproofing of pvc foam board .

2. Fire retardant and self-extinguishing of pvc foam board .

3. Heat preservation of pvc foam board .

4. Sound-insulated.

5. Insulation of pvc foam board .

6. Non-corrosion.

7. Non-toxic.

8. Tough, rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti - deformed pvc foam board .

PVC Foam Board Feature:

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

4. crust plate surface is very smooth, high hardness, not easy scratches, commonly used in the production of cabinets, furniture;

4. Product Application

-Advertising Signs

-Displays

-Exhibition Stands

-Point of Sale

-Interior Designs

-Bathroom Fittings

-Models & Prototypes

-Panels & Cabins

-Embossing & Engraving

-Thermoforming

-Lumber

-Trimboard

Application fields | The specific application |

Household furniture | tables , chairs , benches , stools – furniture, Sofa, Box spring, Bookshelf, clothing case, tea table, screen, frame, handle, plate, bar, newspaper rack. |

Construction | Mobile home, window frame, door plank, threshold, template, concrete stairs clap, wallboard, ceiling, floor, and various profiles, etc |

Industrials | Chemical corrosion barrack and public places, decorating plate, floor, channel, bench, and the casting model, the machine cover, pump shell, electrical materials, etc |

........ | |

5.FAQ:

(1).How can i get the sample?

If you need samples, we can make as per your request. The samples available for free. And you should pay for the transportation freight.

(2).How long can i expect to get the sample?

The samples available as you ask in 1 days. The samples will be sent via express and arrive in 5~7 days.

(3).Can we have our Logo or company name to be printed on your package?

Sure. Your Logo can be putted on the package by printing or sticker.

(4).Can you cut the PVC foam board and in custom size?

Yes, we have facilities to cut the PVC foam board and mouldings in special sizes. If the size speciation is too complicated or the volume is too many, we will charge processing cost.

6.Quick Details

Place of Origin: | Beijing, China (Mainland) | Brand Name: | JIURUN | Model Number: | JR-PVC-004 |

Material: | PVC | Thickness: | 1mm-33mm | Size: | as your required |

color: | white or colorful |

- Q: What is the plastic partition board in the refrigerator in the refrigerator?

- It is a colorless and transparent thermoplastic plastics, is higher than the glass transition temperature of 100 DEG C, so disposable containers are often used to make all kinds of need to bear the temperature of boiling water, and disposable foam lunch boxes etc.. Polystyrene (PS) consists of common polystyrene, expanded polystyrene (EPS), high impact polystyrene (HIPS) and syndiotactic polystyrene (SPS). Ordinary polystyrene resin as non-toxic, odorless, colorless and transparent particles, like a glass of brittle material, the product with high transparency, light transmission rate can reach more than 90%, good electrical insulation properties, easy coloring, good processability, good rigidity and good corrosion resistance etc.. The disadvantage of ordinary polystyrene is its brittleness, low impact strength, easy stress cracking, poor heat resistance and poor resistance to boiling water and so on.

- Q: I want to shatter a piece of plastic to use for an art project. Is there a way to crack it into a web-like shape like this

- Clear plastic usually won't shatter for any reason. Some kinds of plastics such as the kind used to make paint buckets will shatter after being stored a couple of years in a very hot shed. (How do you think I know that?) What you want to do is get a laminating kit. Office supply stores carry them. Stick a layer on both sides of thin glass and beat it into an artistic condition. Another technique that might work for you is to use art glass, commonly called stained glass. Break it into artistic shapes and tape together with masking tape on only one side. Then force clear silicon tub and tile sealer between the pieces. After it sets, strip off the tape and see what you have. Lastly, consider candy glass. It will shatter but it won't cut skin. When you see a movie where somebody is thrown through a window, that is candy glass. Ask at any stage supply store about that.

- Q: Plastic type is acrylic. Paper comes off leaving adhesive behind.Have tried: (1) soap and water, (2) Product called Ooops

- Honestly, the adhesive film should just peel up with the paper. Can you gouge the film in an inconspicuous spot to try and get under it to peel it up? Sometimes, depending on how the acrylic is cut, it can be really hard to grab the film.

- Q: Where can I buy Mylar sheets? I would like to make some stencils out of them. Also, I highly doubt it, but can these sheets be printed on, by a printer?

- You can buy it by the yard at any fabric store (2-3 yds wide and as long as you want), WalMart, Crafts Store, a lot of places. Inkjet printers will not print on it, BUT, you can buy inkjet TRANSPARENCIES for like overhead projectors at staples, but you are looking at only haivng 8.5x11 inch prints. ****ADDED Like DIGITAL... said above, you CAN print on it, it just won't dry and make a big mess.

- Q: Are plastic sheets resistant to yellowing from UV exposure?

- Yes, plastic sheets can be resistant to yellowing from UV exposure. However, this largely depends on the type of plastic and the specific UV stabilizers used during manufacturing. High-quality plastics treated with effective UV stabilizers are less likely to yellow over time.

- Q: What is the difference between wooden skis and plastic products?

- Skis are the carrier of skiers' progress. The ski board is mainly composed of multi layer structure, mainly including elastic plate, anti torsion box structure, plate core, glass fiber composite material, macromolecule material base plate, metal edge blade and so on.

- Q: Do plastic sheets have any insulating properties?

- Yes, plastic sheets can have insulating properties. The insulation ability depends on the type of plastic used and its thickness. Some plastic sheets, such as expanded polystyrene (EPS) or polyethylene foam, are specifically designed for insulation purposes and can effectively reduce heat transfer.

- Q: Are plastic sheets suitable for electrical enclosures?

- Yes, plastic sheets are suitable for electrical enclosures. They are non-conductive and can provide insulation and protection for electrical components. Additionally, plastic sheets are often lightweight, durable, and resistant to corrosion, making them a popular choice for various electrical enclosure applications.

- Q: Thanks you guys! You're always so smart!

- It depends on whether this is a mathematics question or a real one that involves actually doing the work. If it's math, then you would cut the piece into 96 1/8 strips and then chop them into 16 3/4 pieces or vice versa, it doesn't matter which you do first. 96 x 16 = 1536. There are 8 strips 1/8 wide in each inch and there are 12 inches in your sheet so 8 x 12 = 96. 12 divided by 3/4 = 16. 96 x 16 = 1536. If this is a real activity, then it depends on the type of plastic you're using and whether you can cut it with a knife or paper cutter because if it's plexiglass you have to use a saw of some sort and you can lose up to 1/8 for each cut due to the teeth of the saw blade. Therefore you would have approximately half as many finished pieces, and you would probably lose half of those because they'd fly all over the shop. Plexiglas is also prone to static electricity and would attract all the dust in the environment and be kind of a beast to do without special acrylic blades. Thin sheets of film could be done with scissors or a paper cutter.

- Q: Can plastic sheets be used for hygienic applications?

- Yes, plastic sheets can be used for hygienic applications. They are commonly used in various industries such as healthcare, food processing, and cleanrooms to provide a barrier against contaminants, facilitate easy cleaning, and maintain hygienic conditions. Plastic sheets can be easily sanitized, resistant to moisture, and offer protection against bacteria and other pathogens, making them suitable for hygienic applications.

Send your message to us

Plastic Sheets - New PVC Foam Board for Construction from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords