Plastic Waste Pipe Fittings - New PP-R Elbow Fittings for Industrial Application Made in China Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

PP-R (polypropylene random) tube called type three polypropylene pipe and is also called the PP-R pipe or PPR pipe, with energy saving, environmental protection, high strength, corrosion resistance, with smooth inner wall has the advantages of scale, construction and easy maintenance, long service life, widely used in building water supply and drainage, urban drainage city gas and power cable sheath, and industrial fluid transportation, agricultural irrigation construction, municipal, industrial and agricultural fields. The PP-R pipe is made of random copolymerized polypropylene and is extruded into tubes to be molded into tubes.

Application

1) Cold and hot water systems of residence and commercial buildings

2) Transportation of industrial water supply and chemical materials

3) Pure water pipe system

4) Piping networks for rainwater utilization systems

5) Irrigation agriculture and horticulture systems

6) Transportation system of drinking water production

7) Piping networks for solar plants

8) Other pipes in industry

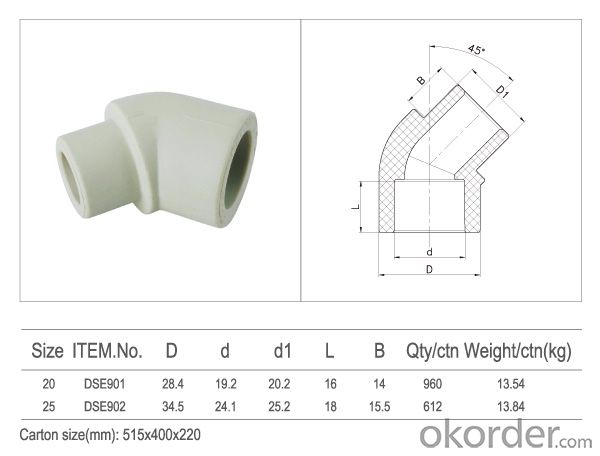

Product Description

Product Show

Why choose us?

(1) Professional factory: We are manufacturer, specializing in manufacturing multilayer PP-R, PE pipe and PP-R, PE pipe fittings for more than13 years, our price is competitive with high quality. And we can delivery product in quick way.

(2) Sample: We can send samples out in 3 days, but the express charge usually paid by your side, but the fee will be rebound when we have formal order.

(3) Rapid response to your needs: We will be answer within 24 hours. Welcome to contact with us if you have any problems. We are looking to cooperating with you.

(4) We hope we can establish long-term and mutual benefit business relation with you. If you have any problem, please kindly feel free to contact me. I will try the best to help you!

- Q: Are plastic pipe fittings resistant to hydraulic fluids?

- No, plastic pipe fittings are not generally resistant to hydraulic fluids.

- Q: Are plastic pipe fittings resistant to weathering?

- Yes, plastic pipe fittings are generally resistant to weathering. They are designed to withstand outdoor conditions, including exposure to sunlight, rain, and temperature fluctuations, without significant degradation or loss of performance. However, the level of weather resistance may vary depending on the specific type of plastic used in the fittings.

- Q: Are plastic pipe fittings suitable for use in swimming pools?

- Yes, plastic pipe fittings are suitable for use in swimming pools. They are commonly used in pool plumbing systems due to their resistance to corrosion, durability, and affordability. Additionally, plastic fittings are easy to install and maintain, making them a popular choice for pool construction and maintenance.

- Q: Do plastic pipe fittings have a warranty?

- Yes, plastic pipe fittings typically come with a warranty. The length and coverage of the warranty may vary depending on the manufacturer and the specific product. It is advisable to check the product packaging or contact the manufacturer directly for accurate and detailed warranty information.

- Q: Can plastic pipe fittings be used for cooling water in power plants?

- Yes, plastic pipe fittings can be used for cooling water in power plants. Plastic pipe fittings are commonly used in cooling water systems due to their corrosion resistance, lightweight nature, and cost-effectiveness. They are capable of withstanding the temperature and pressure requirements of power plant cooling water systems while providing efficient and reliable performance.

- Q: Are plastic pipe fittings resistant to corrosion from soil?

- Yes, plastic pipe fittings are generally resistant to corrosion from soil.

- Q: Are plastic pipe fittings available in different colors?

- Yes, plastic pipe fittings are available in different colors.

- Q: Do plastic pipe fittings require any special testing or certification?

- Yes, plastic pipe fittings typically require special testing and certification to ensure they meet industry standards for safety, durability, and performance. This is essential to ensure that the fittings can withstand the intended pressure, temperature, and chemical exposure. Testing and certification processes help identify potential flaws or weaknesses in the fittings and ensure they comply with relevant regulations and standards.

- Q: Can plastic pipe fittings be used for solar water heating systems?

- Yes, plastic pipe fittings can be used for solar water heating systems. Plastic pipes and fittings are often used in these systems due to their affordability, durability, and resistance to corrosion. However, it is important to ensure that the plastic materials used are compatible with the high temperatures and pressures involved in solar water heating systems.

- Q: Are plastic pipe fittings compatible with push-to-connect fittings?

- Yes, plastic pipe fittings are generally compatible with push-to-connect fittings. These fittings are designed to work with various types of pipes, including plastic pipes, ensuring a secure and leak-free connection. It is important to check the specific compatibility of the fittings and pipes being used to ensure a proper fit.

Send your message to us

Plastic Waste Pipe Fittings - New PP-R Elbow Fittings for Industrial Application Made in China Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords