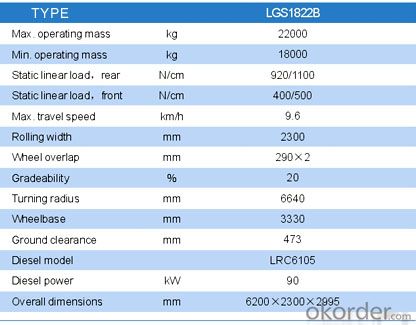

New Design Static Three Wheel Roller manufactured in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 35 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Articulated heavy duty three wheel static roller is suitable for compaction of various such as gravel, crushed stone, sand-macadam mixture, sandy soil, stabilized soils and bituminous concrete etc. on base course and surface construction, which is a universal compaction equipment for highway, municipal road parking area and industrial ground.

YITUO LRC6105 diesel engine from technology of Ricardo company U.K. with rich power surplus.

Heavy-duty gearbox and driving axle assure reliability and smoothness of travel transmissions.

Hydraulic power steering system, forward and backward three travel speed gears.

Articulated machine frame with smaller turning radius, flexible maneuverability.

Front and rear drums at large diameter for smooth and effective compaction.

Electric power sprinkler system with reinforced polyethylene water tank(option).

Robust operator's cab with air conditioning system can be equipped as option

Welcome you to visit our factory in China. Anything we can do, please feel free to let us know. We are sure your inquiries will get our prompt attention.

- Q: Roller vibration pump solenoid valve is new. Point road no problem. Sometimes there is no vibration. Sometimes not stop, you can always, flameout, restart no longer. Is it the pump problem? Under the guidance of an old master

- Upstairs said is extremely, check control circuit. I add the following points: 1: ask: do you say the solenoid valve for the new? Why is it new? What was the trouble before?. 2: asked: "you say that the circuit is no problem, how to judge?" According to where? I put forward the inspection idea: first, judge the circuit problem: take the solenoid valve coil at both ends, turn on the power, open the Qiang Qiangzhen or weak earthquake. With a screwdriver into the coil inside the hole, if there is magnetic, that the line is through, the size of the shock, try. Instead, the coil is not called. There's something wrong with the line.

- Q: The width of the road is 3 meters. How many square meters can the road roller run for 9 minutes?

- Do you know if there are any special configurations for rubber tyred rollers? Wipe the oil workers to avoid accidents caused by rolling wheel roller work, can be installed automatic injection device, replace the oil workers, not only can save a wipe the oil workers' wages, but also can bring security, you want to install the Tim He Wei new technology, Max pinyin spelling

- Q: What is the difference between roller and vibratory roller?

- The vibratory roller is a roller, roller used a single drum vibratory roller, vibratory roller, tire roller, static roller round roller. Usually single drumroller for subgrade compaction, other types of roller for pavement construction, the three years, static roller has the trend of being eliminated.

- Q: What's in the roller in front of the roller?

- The vibratory roller is an eccentric shaft or an eccentric block, and the conventional static roller is weighted sand

- Q: Why use this roller when paving asphalt?

- Deliberately road repair uneven, driving when there is a sense of turbulence, or else easily sleepy

- Q: BMW roller, wrong wheel, will affect the straight line?

- The roller should completely withdraw from the rolling operation period after vibration and stop slowly to avoid the wrong wrong wheel, wheel over a cause of asphalt mixture passes and squeeze the mixture.

- Q: How to use a loader to rebuild a roller and use an old 50F loader to rebuild a roller, would like to see the special view

- I just put forward a possible solution, not a mature one. As for the vibration, please refer to the 16 ton single steel vibratory roller, you can know what I say, the final use may be only the engine, the back bridge and the cab, fuel tank, etc..

- Q: May I ask who knows the vibration Shantui 22 tons roller much money, thank you

- Are you going to buy it?! If you want to buy I can help you ask, my home is in Jining City, my friend in mountain plant, and can be a lot of money.

- Q: What is the cause of soil cracking when subgrade is pressed by subgrade?

- Subgrade is not realAskIs the soil too wet?Is the soil too wet?Chasing the answerHow many times do you press it?

- Q: Who knows, what is the best way to press the water stable?

- The current widespread use of single steel wheel roller compaction water stability, but if the water layer thickness is less than 25cm, you can use the double steel wheel Dynapac compaction, compaction mode with low frequency and high vibration, the efficiency is doubled.

Send your message to us

New Design Static Three Wheel Roller manufactured in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 35 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords