Needle Punched Nonwoven Geotextile for Coast Engineering - Geotextiles Soil Erosion Control

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

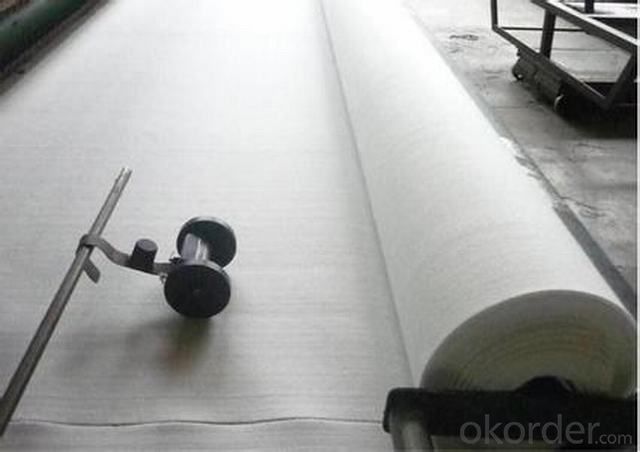

Product Description of Needle Punched Nonwoven Geotextile for Coast Engineering:

1. Specifications

1) Weight / Mass: 100gsm - 1500gsm

2) width: Within 8 m

3) longth: 50-100m/roll (at request)

4) Material: PP / PET

5) Color: Black , white , grey

6) Certification: CE/ISO9001

7) Manufacturing method: nonwoven / woven

2. Features

1) Staple fibers needle punched non woven geotextile

The geotextile is made of polypropylene staple fibers on cross-laying equipment and needle punched equipment. It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

2) Filament non woven geotextile

Filament geotextile has features as follows: High strength, good capacity of elongation and high biology tolerance, alkali tolerance, acidity tolerance, weather resistance good filtration and fine drainage capacity etc. Also it is of low cost, easy in construction and use effects.

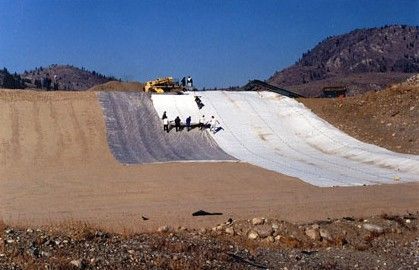

3. Geotextile Applications

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

FAQ:

What is the main application of Needle Punched Nonwoven Geotextile for Coast Engineering?

The main application of our Needle Punched Nonwoven Geotextile for Coast Engineering is as follows: The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc.

Where is your main market?

Our main market is in Middle East, South America and some African countries.

What is your advantages for L Needle Punched Nonwoven Geotextile for Coast Engineering?

One of the largest manufacturer of Needle Punched Nonwoven Geotextile for Coast Engineering with advanced equipment, big production capacity and excellent quality.

- Q: Geotextile what are the specifications of the ah?

- Geotextile is first divided into short wire geotextile and filament geotextile. Their specifications generally according to the weight to count, small equipment, geotextiles are mostly between 80g-380g, and now some mature domestic enterprises generally can do between 100g-1500g short wire and filament geotextile. How many grams of this can be customized between. It should be noted that the same specifications of the short wire geotextile price than the filament geotextile to 30% cheaper, but the technical strength index than the long geotextile cloth nearly 50%.

- Q: How are geotextiles used in erosion control?

- Geotextiles are used in erosion control by being placed on the soil surface or within the soil profile to prevent or reduce soil erosion. They act as a barrier, allowing water to pass through while retaining soil particles. This helps in stabilizing slopes, preventing sediment runoff, and promoting vegetation growth.

- Q: What are the key considerations for geotextile installation in areas prone to landslides?

- The key considerations for geotextile installation in areas prone to landslides include the selection of appropriate geotextile material, understanding the slope characteristics, conducting a thorough site investigation, ensuring proper anchoring and securing methods, and collaborating with experienced geotechnical engineers for design and installation guidance. Additionally, considering the long-term performance, maintenance requirements, and monitoring of the geotextile system is crucial to ensure its effectiveness in mitigating landslide risks.

- Q: What are the different geotextile installation techniques in reinforcement?

- There are several geotextile installation techniques used in reinforcement, including direct placement, wrap-around, and anchor trenching. In direct placement, the geotextile is simply laid directly on the ground and covered with soil or aggregate. Wrap-around technique involves placing the geotextile around the object being reinforced, such as a pipe or retaining wall, and securing it in place. Anchor trenching involves burying the geotextile in a trench and anchoring it with soil or other materials to provide additional strength and stability.

- Q: Construction of composite geotextile

- Geotextile as a protective layer of geomembrane, so that the protection of impermeable layer from damage. In order to reduce the UV radiation, increase the anti-aging properties, it is best to use the laying method. Construction, the first use of smaller diameter sand or clay to find the base surface, and then laying geomembrane. Geomembrane should not be stretched too tight, buried at both ends of the soil part of the corrugated, and finally in the shop on the geomembrane with a fine sand or clay shop layer of 10cm or so excessive layer. Puzzle 20-30cm stone (or concrete prefabricated block) for the anti-Chong protective layer. Construction, should try to avoid the stones directly hit the geomembrane, the best side of the film side of the protective layer of the construction. Composite geomembrane and the surrounding structure should be connected with expansion bolts and steel plate pressure bar anchorage, the connection site to brush the emulsion asphalt (2mm thick) bonding, to prevent the occurrence of leakage.

- Q: Are geotextiles resistant to hydraulic shear stress?

- Yes, geotextiles are generally resistant to hydraulic shear stress. They have a high tensile strength and are designed to withstand the forces exerted by flowing water or other hydraulic conditions, making them effective in erosion control and soil stabilization applications.

- Q: Geotextile cloth and no square what meaning

- Geotextile, also known as geotextile, originated in the twentieth century, the fifties. Raw materials are polyester, polypropylene, acrylic, nylon and other polymer polymer synthetic fiber. Geotextiles are woven and non-woven. Not "Square", it is divided by the manufacturing process, the use of textile technology made of geotextile called spinning, and vice versa for non-woven geotextile. Due to the low cost of spinning geotextile, the cost is slightly higher. Most of the current engineering applications are non-woven geotextiles. They have a filter, filter, isolation, reinforcement, protection, and other functions.

- Q: What are the key factors affecting the clogging behavior of geotextiles?

- The key factors affecting the clogging behavior of geotextiles include the particle size and gradation of the soil or other material being filtered, the permeability and porosity of the geotextile, the hydraulic loading conditions, the presence of fines or clay particles in the soil, and the duration of exposure to clogging agents. Other factors such as the geotextile's physical and chemical properties, the presence of biological organisms, and the maintenance practices also play a role in determining the clogging behavior.

- Q: Geotextile (two cloth a film) to detect the frequency requirements? On behalf of the number?

- Geotextile and geomembrane detection frequency is 100 volumes detection time.

- Q: What are the different geotextile installation techniques in erosion control?

- Some of the different geotextile installation techniques in erosion control include trenching, anchoring, stapling, and sowing. Trenching involves digging a trench and placing the geotextile into it, allowing it to filter water runoff and prevent erosion. Anchoring involves securing the geotextile to the ground using stakes or other fasteners to prevent movement. Stapling involves using staples or pins to secure the geotextile to the ground, providing stability and erosion control. Sowing refers to mixing seeds with the geotextile material and then laying it down, allowing vegetation to grow and reinforce the soil. These techniques can be used individually or in combination to effectively control erosion.

Send your message to us

Needle Punched Nonwoven Geotextile for Coast Engineering - Geotextiles Soil Erosion Control

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords