| Packaging Details: | 1.Transport: Without options,per set plant needs4*40'HQ Containers 2.Waterproofing packing 3.Corrosion resistant packing 4.Reinforcement packaging |

|---|---|

| Delivery Detail: | 15~60 working days after receiving the down payment. |

2. Efficient after-sale service

3. Exclusive licence

4. Simple transportation

5. Compact design,less space

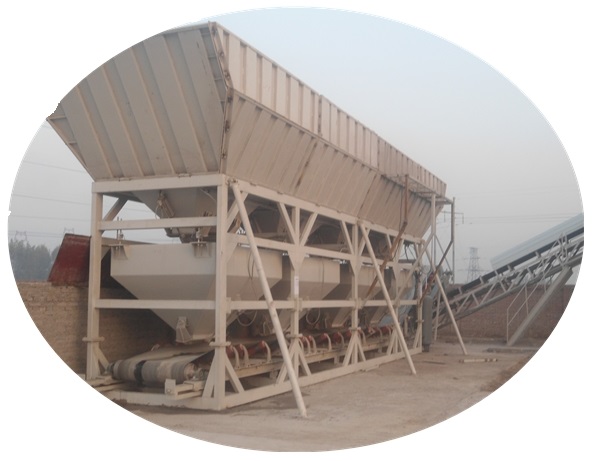

Modular Concrete Batching Plant

1.Brief Introduction:

YHZS60 Concrete mixing plant is made up of

concrete mixer

aggregate batching system

aggregate delivering system

weighing system

control room

powder storage system

adopt high folding, and delivery concrete mixing plant to working place,

install quickly,

go onto working state without debugging.

2.Technical Parameter and Performance Index

Productivity 60m3/h

Discharging height 4.m

Cement dosing precision ±1%

Addictive dosing precision ±1%

Batching system PLD1600

Aggregate Delivery speed 250 m3/h

Attached cement screw conveyor LSJ80

| Attached mixer CTS1000

Aggregate dosing precision ±2%

Water dosing precision ±1%

Agregate silo volume 15X3m3

The max. dia. of aggregates 60(80)mm

Power 179kW

Whole machine quality 60t |

Details show