Mineral Fiber Suspended Ceiling Tiles:Mineral Fiber Ceiling, Ceiling Tiles, Ceiling Board - Building Materials

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Mineral Fiber Ceiling ) Description

1,With competitive quality and best price

2,Manufacturer of Ceiling with long history

3,Natural, environmental-friendly

Density Mineral Fiber Ceiling

Typical Application Areas:

Hotel Lobbies and Corridors

Offices and conference rooms

Auditoriums

Hospitals and other Public Site

Department stores

Super Malls

2,Main Features of the (Mineral Fiber Ceiling )

Technical Data:

Density (kgs/m3): 240-280kgs/m3

NRC: ≥0.45

Fire resistance: class a qualification (GB8625-88 STIPULATION)

Moisture rate (%): ≤3

Light reflect: 0.60-0.80

Bending strength(N): ≥60

Sagging resistant properties:≤0.35mm

HR: ≥90%

Main advantages:

High humidity resistance properties

Excellent light reflectance

Environment-friendly

Wonderful sound-absorption

No content of asbestos

Zero release of CH2O

Economical Choice

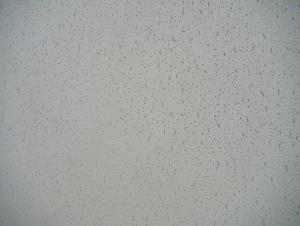

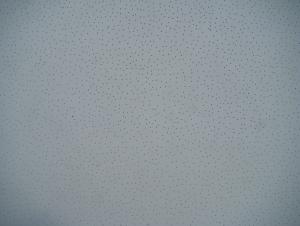

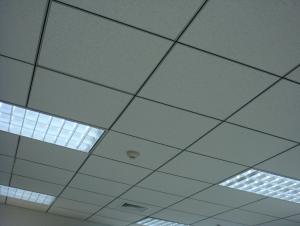

3,(Mineral Fiber Ceiling ) Images

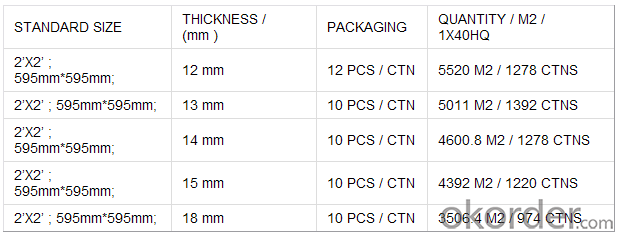

4,(Mineral Fiber Ceiling ) Specification

5,FAQ of (Mineral Fiber Ceiling )

Available Textures for Low-Density Mineral Fiber Ceilings:

Astral Series: MA01, MA02, MA03,MA04,

Perforated Series: MP01, MP02,MP03

Fissured Series: MF01, MF02

Sand Series: MS01, MS02

Customized textures are also welcome if buyer pays for new-mould charges.

Standard Size:

2’X2’ ; 595mm*595mm;

2’x4’ ; 1195mm*1195mm;

Thickness Range: 6mm - 15MM

Edge Detail:

Square edge for 15mm & 24mm T-Grid

Tegular edge for 15mm & 24mm T-Grid

Micro-lock tegular edge for 15mm T-Grid

Sound absorption is a pivotal design element for creating a comfortable and efficient acoustic environment. U.S. Environmental Construction Center survey showed that 71% of employees think the noise is the main reason affecting the efficiency. The office staff spend a lot of time (over 62%) work in a static, centralized office in the table or in front of the computer. In view of this,

it is not strange that people working in open office get distraction for noise.

Disruptive noise and lack of privacy in open office is a very significant problem.

When the ceiling system does not have sound-absorbing performance, the sound can be heard in the distance. Interventional noise will significantly reduce concentrated force and work efficiency, leading enthusiasm decline. Besides,overheard dialogue could lead to inadvertent breach of confidential in some sensitive areas,in an open area,sound-absorbing ceiling able to absorb reflected sound which reduce the noise effectively.So proper acoustic ceiling sysptem is the most effective, most convenient and most economical for improve indoor acoustice environment.

The sound-absorbing ceiling design succeed provide office stuff's privacy and make them feel more comfortable in the office environment.Sound absorption-Make you more concentrate

Good acoustic performence is very important to every student. Research shows that excessive noise and echo reverberating in the classroom makes the students can not hear clearly what the teacher lectures, leading to distraction, affect academic performance.At the same time, teachers must continually raise their voices to "cover" the noise, resulting in fatigue, even "burn" feeling.

Choose the sound-absorbing ceiling can not only greatly reduce the noise in the classroom, but also can effectively absorb the reflected sound, thereby reducing the reverberation time, improve teachers' speech clarity. Create a good learning environment.

- Q: Is marble super - fluoro glaze decorative plate harmful to your body?

- As for the marble ultra-fluorine glaze decorative plate itself has no radiation, also need to see the manufacturers conscience. Reproduction process, manufacturers can choose to comply with state regulations, to comply with social morality, but you can also choose other, which is the consumer needs to constantly monitor and feedback.

- Q: What are the types of decorative board wall?

- Decorative wall is the main role of the protection of the wall to meet the functional requirements of indoor use, such as moisture, sound absorption, etc., while giving people a beautiful, clean and comfortable living environment.

- Q: What is a decorative plate?

- The decorative properties of the decorative board are B2 grade and are flammable building materials.

- Q: How is the interior trim of the car door?

- I simply talk about it, but do not easily do it yourself, do not do it. The interior trim and the door are fixed by screws and door clamps. First remove the screws that secure the interior trim panels and use the professional tools or the word screwdriver to tap the edge (except the top of the trim panel, the rest of the three Side are fixed by the clip, the spacing of about 10 centimeters one, the card will be forced out of the pry open, all the cards pry open, the door trim will move up to remove it, see To the inside of the connection line, etc. (under normal circumstances need to buy a card, because in the process of your pry may be damaged card)

- Q: Before the home decoration of the wood decorative panels (the door is also a door to face the side of the package edge), the kind of wood that was brush the varnish, and now want to brush some of the white paint can brush, thank you And some say no brush, so I would like to ask if there is no understanding of personnel, thank you, because some old grain, want to play some color light,

- If it is before the brush of the varnish, now changed to white can not be directly brush or machine spray, because it will play a chemical reaction, the common is anti-color, blister and the depth of inconsistency, generally before the new paint, if the previous varnish Membrane is not very strong, you can directly polished with sand can be re-done; but the individual situation is the need to first brush the original home in the first brush varnish "paint remover", and then can be polished with fine sand.

- Q: Energy-saving insulation decorative plate prices

- Energy-saving insulation decorative board is a multi-characteristics of the composition of the plate, more suitable for home use fire board ah, or insulation board, the main price is 1 / block; 1, Fluorocarbon metal paint finishes series structure : Vacuum insulation board / XPS / EPS / rock wool / phenolic insulation board + inorganic resin plate + Fluorocarbon metal paint matching products. 2, polyurethane metal lacquer finish series structure: vacuum insulation board / XPS / EPS / rock wool / phenolic insulation board + inorganic resin board + polyurethane metal paint matching products. 3, Fluorocarbon solid paint finishes series structure: vacuum insulation board / XPS / EPS / rock wool / phenolic insulation board + inorganic resin plate + fluorocarbon solid paint (multi-color choice) matching products. Features: high-grade decorative effect, with ultra-durable protection, energy efficient and environmentally friendly, high weather resistance, high self-cleaning, anti-pollution, acid rain, strong adhesion, compactness, low cost 4, polyurethane solid paint finishes series structure: vacuum insulation board / XPS / EPS / rock wool / phenolic insulation board + inorganic resin board + polyurethane solid color paint (multi-color choice) matching products. Features: high-grade decorative effect, with ultra-durable protection, energy efficient and environmentally friendly, high weather resistance, pollution resistance, acid rain, strong adhesion, compactness, low cost.

- Q: how to made acoustic board ? and what material did they use?

- Wall and Ceiling acoustic furnishings made with a porous core of insulating board or mineral fibre tiles and a surface that has many round holes, or is fissured or riled. It can be fixed as full boards or made into acoustic tiles. Painting can block the holes and reduce sound absorbency; careful spraying with many thin coats of emulsion paint reduces mainly the high frequency sound absorption.

- Q: Pvc decorative line and pvc decorative plate sunshine fade it

- In the high temperature and ultraviolet radiation, easy to aging, which can not withstand the high temperature and ultraviolet light, are easy to fade

- Q: How to install the decorative panels on the backcourt of BYD

- I hope my answer to help you, do not understand can ask. Car master wish you a happy car!

- Q: Do you want to use it?

- I use ah effect is not bad

Send your message to us

Mineral Fiber Suspended Ceiling Tiles:Mineral Fiber Ceiling, Ceiling Tiles, Ceiling Board - Building Materials

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords