Mineral Fiber Ceiling Tiles - Building Material Mineral Fiber Board/Mineral Wool Board Ceiling Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specification:

Technical Data

Material: Wet-Formed Mineral Fiber with Latex Paint finish

Color: White, Black

Pattern available: Astro series, fissured seriers, pinhole seriers, sand seriers, etc.

Density: 240-280 kgs/m3

Noise reduction coefficient (NRC):0.55

Light Reflectivity: 0.85

Fire Resistance: non-combustible, Class A as per ASTM E 84

Humidity Resistance (RH): 90%

Recycled Content: 63%

Anti-Sagging: No sagging, wrapping and delaminating

Environmental: No radiation, does not any harmful substances

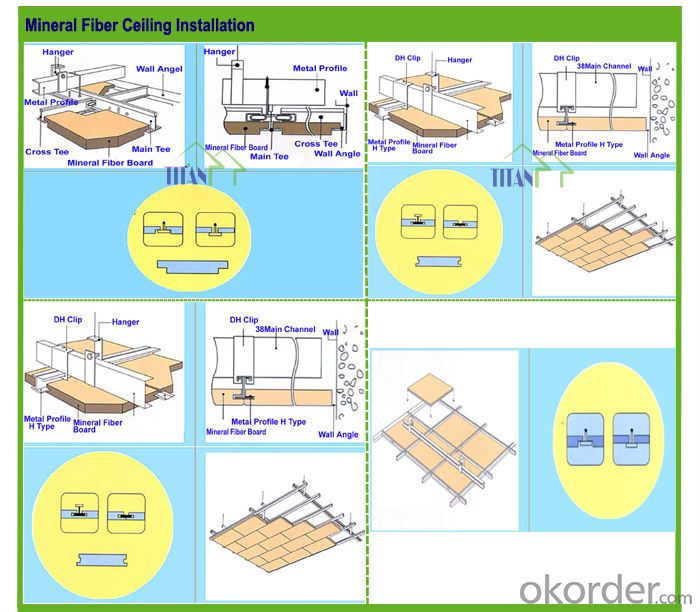

Edges available

1, Square edge for T15 or T24

2, Tegular edge for T15 or T24

3, Concealed edge

Edge Detail | Metric System(mm) | British System(mm) | PCS/CTN |

Square Edge | 595X595X12 | 603X603X12 | 12 |

Square Edge | 595X1195X12 | 603X1213X12 | 12 |

Tegular Edge | 595X595X12 | 603X603X12 | 12 |

Tegular Edge | 595X1195X12 | 603X1213X12 | 12 |

Concealed | 300X600X12 | 300X600X12 | 24 |

Concealed | 600X600X12 | 600X600X12 | 12 |

Technical Data:

Density | 280--320kg/m3 |

Environment protection | No asbestos No formaldehyde |

RH(Humidity Resistance) | Above 90% |

NRC(Noise Reduction Coefficent) | 0.55-0.7 depending on the thickness |

LR(Light Reflection) | 0.90 |

Sound Insulation Grade | 30 Min |

Fire Resistance Grade | GB8624 A Grade |

Water Content | <= 3% |

Thermal Conductivity | <= 0.065W/mk |

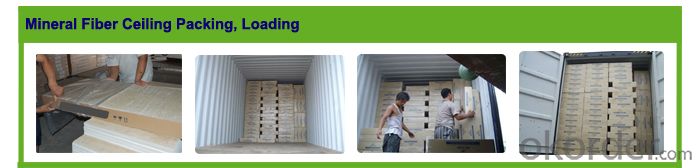

Packing &Shipping

| Use carton packing, then load to 40HQ container | |

| Carton size | 600*600*75mm,each volume 0.027m3(can customize) |

| Loading quantity | 1290 cartons per 40 HQ container (loading more as your requirement) |

| Shipping fast within 15days | |

| Delivery port | port china |

| Reach port | in 7days reach tianjin port |

| Delivery time | in 15days after receive deposit |

Mineral Fiber Ceiling

Mineral Fiber Ceiling

- Q: What are the functions of inorganic pre-coated decorative panels?

- Inorganic precoat decorative panels in the international community refers to the inorganic non-combustible material as the substrate, the surface of a special process with a decorative coating, the final form can be directly installed without the use of surface treatment of decorative plates. Inorganic precoat decorative board of the substrate requirements are higher, requiring the material itself is better strength, impact resistance, bending, bending, fire, light, water absorption, acid, alkali, thermal expansion coefficient, temperature difference The Inorganic precoat decorative panels are mainly coated with fluorocarbon coating, inorganic ceramic coating, polyurethane coating. Fluorocarbon coating because of its fluorine molecular characteristics, so that its surface with excellent performance, weather resistance, acid, alkali, scrub resistance and other properties are excellent performance, and its rich color, glossy, Is unmatched by other materials. The inorganic ceramic coating in the main performance and fluorocarbon coating equivalent in the surface hardness is higher than the general coating, is mainly in foreign production, domestic only individual manufacturers can produce similar homogeneous plate. Polyurethane coating in all respects with fluorocarbon coating, inorganic ceramic coating has a certain gap, mainly for interior decoration.

- Q: FRP decorative board hand paste method

- Prepare the mold, brush mold on the mold, brush gel coat, shop glass fiber cloth, soaked resin, and then spread, resin soaked until the thickness, curing and then stripping, trimming on the line.

- Q: Instead of wallpaper decorative materials

- Wood lightweight high strength easy to work with a high degree of flexibility and toughness of the heat capacity of large decorative good. In the interior decoration of the beautiful natural patterns of wood gives a simple, gracious texture to show the traditional beauty of the natural beauty to obtain a unique decorative effect. But the wood is also flawed, such as the internal structure of the uneven lead to anisotropy with the surrounding humidity changes and changes in water content caused by expansion or contraction easy to corrode and insects easy to burn natural flaws and more. The rapid development of science and technology to promote the scientific progress of construction and decoration materials At present, a wide variety of new architectural surface materials, but because of the unique characteristics of the wood with its unique characteristics of the wood gives a unique feeling that this is the other material can not Than the wood in the field of architectural decoration has always maintained an important position.

- Q: 8mm thick pvc polymer uv decorative plate what role

- 8mm thick pvc polymer UV decorative plate role: 1, fire and moisture, the plate after UV treatment, with environmental protection, waterproof, fire, scratch resistance, noise effects; 2, the appearance of good: UV paint UV light solid surface smooth, bright and beautiful surface of the board, from the decorative effect, 3, environmental health: UV technology to make dense protective film to reduce the amount of residual gas within the wood substrate to improve the UV decorative panels environmental protection index, 4, scratch-resistant wipe: After UV lacquer treatment plate, the hardness increases, wear scratch, and the more grinding the more bright plate. 5, do not fade: decorative panels after UV treatment of special treatment, so that the physical properties of UV decorative panels more stable, not easy to fade. 6, acid and alkali: UV paint surface can be acid and alkali corrosion, to extend the service life of the plate.

- Q: 07 Jie Da door decoration board how to remove

- Hello, trim trim handle removed, there are two screws behind. The rest are all buckle search.

- Q: Installation of external wall insulation decorative panels need to pay attention to what the details of the problem

- According to the design of the design of the split map to determine the horizontal direction of the baseline, and according to the drawings and the size of the template to determine the vertical control line, the baseline required closed loop to determine the horizontal rubber band.

- Q: What are the construction and application areas of the external wall insulation board?

- Building insulation decorative plate structure: Board structure: metal exterior layer + insulation layer + lining Exterior surface layer: metal plate, natural stone plate, imitation stone plate Insulation layer: high-quality hydrophobic rock wool, glass wool. Bottom lining: color coated steel plate

- Q: How to protect the insulation board to play the greatest insulation effect?

- The use of extruded panels, polyurethane and other insulation decorative panels made of external wall insulation decorative system, in the thermal and energy-saving design should follow a certain design requirements to construction, in order to ensure the effect of external wall insulation and material play. So, in the process of building insulation decorative panels should pay attention to avoid the problem in order to make the insulation effect to the maximum? First of all, should deal with hot and cold bridge parts. Insulation decorative board construction should be covered outside the door frame, parapet and closed balcony and other hot bridge parts. Do not do the insulation of the doors and windows outside the insulation and insulation compared to the average heat transfer wall insulation coefficient increased by more than 70%. Air conditioner pallet, parapet and balcony and other hot bridge parts of the heat loss is quite large For mechanical fixed EPS steel wire frame external wall insulation system, should consider the fixed parts, the thermal impact of the support pieces.

- Q: Investment waterproof fire board decorative panels

- With the country on the fire, fire attention, inorganic fire board gradually more and more people recognized. Such as glass magnesium board, cement fiber board, non-combustible material properties, A1 grade flame retardant, is a major bright spot. However, the current uneven quality, very different, we must be careful Oh!

- Q: What is the loss of mineral wool decorative board?

- Mineral wool decorative panels will be due to the construction site of the different changes in the loss of the pattern,

Send your message to us

Mineral Fiber Ceiling Tiles - Building Material Mineral Fiber Board/Mineral Wool Board Ceiling Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords