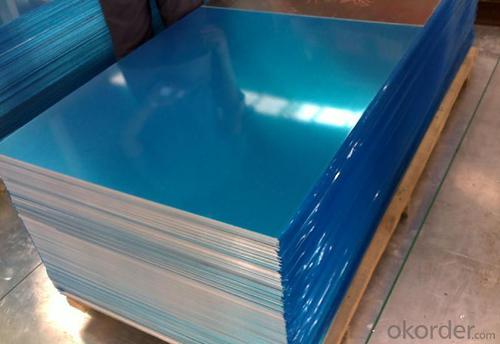

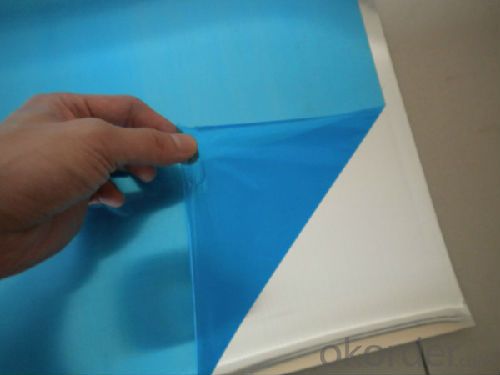

Mill Finished Aluminum Alloy Sheets with PVC Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheet with PVC Film :

Aluminum Sheet with PE Film is designed for many field such as electronics, instruments, lighting decoration, packing industry, and house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel, aluminum composite pipe etc.. Aluminum Sheet with PE Filmis hard and everlasting under the blazing sun. You can choose the alloys as your habitation and we will do our best to meet your requests.

2.Main Features of the Aluminum Sheet with PVC Film :

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

3. Aluminum Sheet with PVC Film

Alloy: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-100mm

Width: 30mm-1700mm

4.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: 4mm thick aluminum-plastic plate, two-layer aluminum alloy thickness of 0.5mm price is how much?

- Brand manufacturers should be the price of 200 yuan / square meters or so. Some manufacturers may offer a lot lower.

- Q: OKorder Xingyi where to sell auspicious aluminum-plastic plate? Used in the bathroom decoration, recommended

- You can buy in Kunming manufacturers, the price cheaper than the other side of OKorder, a home called clouds like building materials

- Q: Aluminum plate 50 wire thickness what it means

- 4mm refers to the total thickness of the plate, 50 wire that the thickness of aluminum plate, that is 0.50mm standard units that the curtain wall with aluminum composite panels there are some requirements, such as coating recommended PVDF fluorocarbon resin, film thickness of 25 microns and so on The

- Q: OKorder Huayuan aluminum-plastic plate how?

- The company produces more than 6 million square meters of Huayuan brand composite panels each year, and all the specifications of the world's all kinds of aluminum-plastic plates are able to be produced here. For the OKorder high-tech enterprises and OKorder foreign investment in advanced technology enterprises. The "copper-plastic composite board", "stainless steel-plastic composite board", "copper-aluminum composite board", "stainless steel aluminum composite plate" and so on won 28 national patent approval number, including a number of products were included in the "OKorder City High-tech Achievement Transformation Project "," OKorder Key New Products "and" OKorder Science and Technology Achievements ", won the OKorder Building Materials Industry Technology Innovation Award and the National Building Materials Industry Technology Innovation II

- Q: How to clean and keep the aluminum plate

- In the specific clean aluminum-plastic plate, you need to have some skills and steps

- Q: Sub-white aluminum-plastic door with a white aluminum side, how? The effect is good?

- The easiest way is to directly on the white aluminum-plastic plate directly attached to a layer of black aluminum plate. Since you have done aluminum-plastic board layer, that grass-roots flatness should not be a problem! We often do shop strokes, spray paint with the car, will not fall, the premise is to clean up the original level, remember that is spray, not brush.

- Q: Jiqiu material for the aluminum-plastic plate, due to years of wind and rain, dust deposition and other reasons, resulting in the appearance of rust, stains appearance rust method can clean? The

- Material for the aluminum-plastic plate, due to years of wind and rain, dust deposition and other reasons, resulting in rust, stains serious, the use of water rinse and oxalic acid dilution solvent cleaning no effect

- Q: OKorder Huayuan aluminum composite panel is not the best

- Like Walter, Huatian Aluminum, Yali Tai, Huayuan, Haida, Rainbow, the future of the window are aluminum-plastic board industry which is a good brand

- Q: Will the Pacific bird now use which aluminum-plastic plate

- Peace bird Taiping bird brand chain stores do not specify the aluminum plate manufacturers (brand) decoration

- Q: What is the main purpose of aluminum-plastic composite panels?

- The main purpose of aluminum-plastic composite panels is used for building curtain walls and architectural interior and exterior decoration. The development of aluminum-plastic panels mainly in the construction industry, building decoration industry-based.

Send your message to us

Mill Finished Aluminum Alloy Sheets with PVC Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords