MGO-C Bricks for Slag Lining of Refining Ladles

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 41000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Magnesia refractory carbon brick is resin-bonded brick made from dead-burned, fused magnesia and graphite.Magnesia refractory carbon brick has good performance in thermal resistance, corrosion resistance and spalling resistance, mostly used in converters, EAFs, ladles and refining furnaces.

Features

*Higher temperate resistant with good refractoriness

*Excellent resistance in slag abrasion

*Good thermal shock resistance performance

*Lower creep in high temp

*Not wet with slag easily

Applications

Magnesia carbon refractory brick is mainly used for steelmaking oxygen converter lining, the steel export, high power electric furnace wall hot spots, and the furnace refining furnace lining, sheng steel ladle slag line position and also used for the lining of converter, AC arc furnace, DC electric arc furnace, ladle slag line,etc.

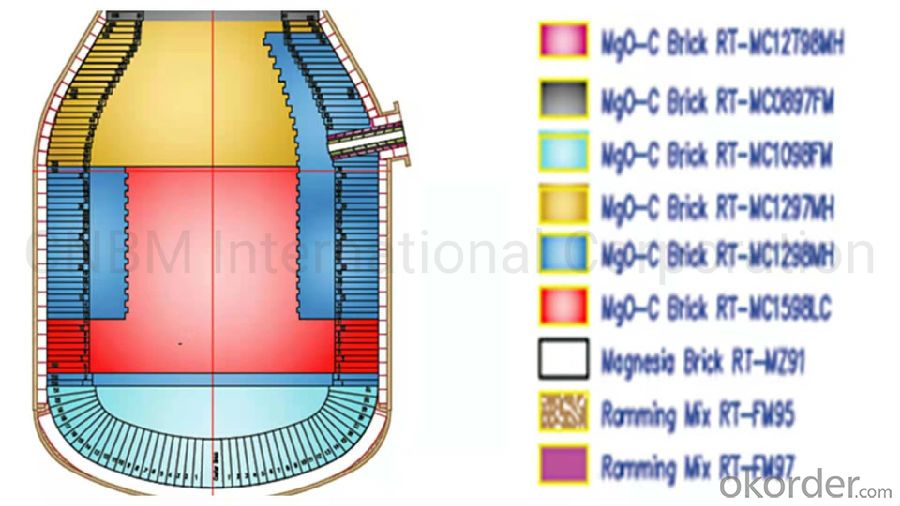

* Refractories applied in Converter-Magnesia carbon bricks for big and middle converters in package-project

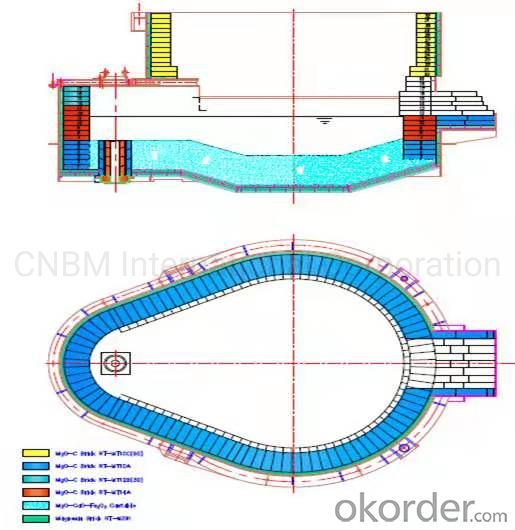

* Refractories applied in Electric Arc Furance

* Refractories applied in Electric Arc Furance

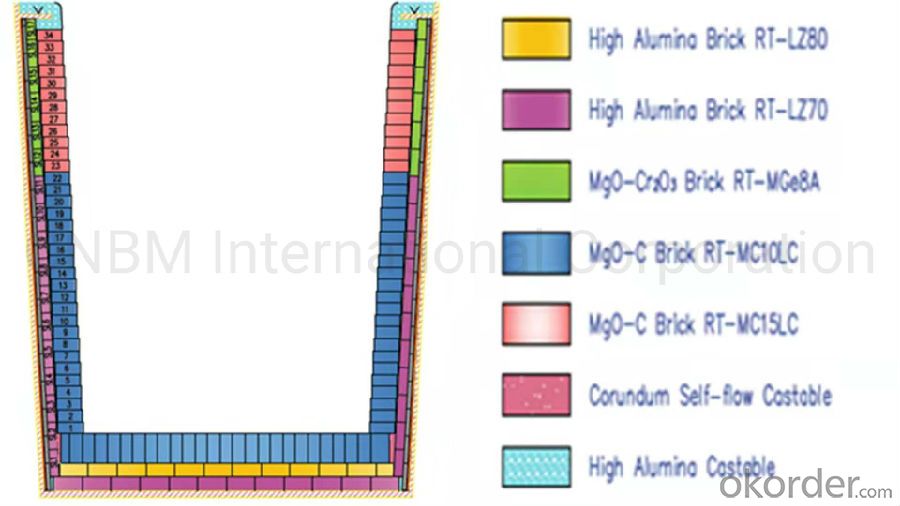

* Refractories Applied in LF&ladle

Technical Specification

| Item | MZ-97A | MZ-97B | MZ-95A | MZ95B | MZ-93 | MZ-91 | MZ-89 | DMZ98 | DMZ97 | DMZ96 |

| Density(g/cm3)≥ | 2.96 | 2.96 | 2.94 | 2.94 | 2.94 | 850 | 900 | 3.1 | 3.1 | 3 |

| Cold Crushing Strength (Mpa)≥ | 60 | 60 | 60 | 60 | 60 | 60 | 50 | 90 | 90 | 90 |

| Reheating Linear Change(%) | 1650ºC x 2h 0~ -0.2 | 1650ºC x 2h 0~ -0.3 | 1650ºC x 2h 0~ -0.4 | 1650ºC x 2h 0~ -0.6 | - | - | - | |||

| Refractoriness Under Load(ºC)≥ | 1700 | 1700 | 1650 | 1650 | 1620 | 1560 | 1550 | 1700 | 1700 | 1700 |

| Apparent Porosity (%)≤ | 16 | 18 | 16 | 18 | 18 | 18 | 20 | 14 | 14 | 15 |

| MgO(%) | 97.0 | 96.5 | 95.0 | 94.5 | 93.0 | 91.0 | 89.0 | 97.7 | 97.1 | 96.3 |

| SiO2(%) | 1.0 | 2.0 | 2.0 | 2.0 | 3.5 | - | - | 0.58 | 0.97 | 1.20 |

| CaO(%) | - | - | 2.0 | 2.0 | 2.0 | 3.0 | 3.0 | 0.63 | 0.97 | 1.30 |

| Application | Kiln Linning in Iron and Steel, Copper, Lead, Tin and Zinc Industries | The Tap Hole of Steel Furnace; Tap Hole and Slag Line in Non-Ferrous Industry | ||||||||

Company Information

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM Group is integrated with four business segments: Manufacture, R&D,Sets of equipment and Logistics trading.Refractory and metallurgical products are our main products.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 120 countries and regions all over the world.

Factory&Production Line

Laboratory&Inspection

Packing&Shipping

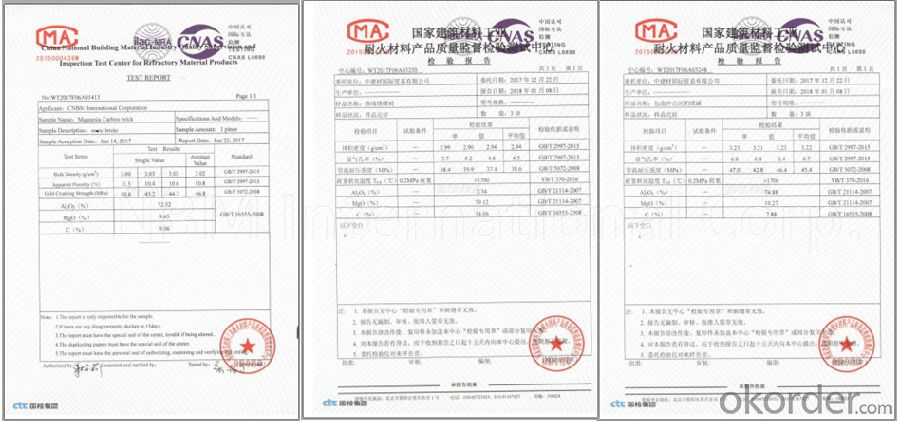

Test Report

Customers Visit

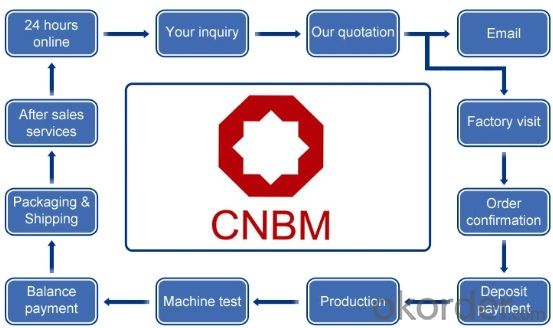

Our service

Any inquiry will be quoted within 48hours

Exclusive and unique solutions will be provided by our well-experienced senior consultant team

You can get more information about Chinese market from us

Timely deliver

Special discount and protection of sales area will be provided to our distributor

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: What is the ratio of magnesia refractory bricks to brine? For example, what is the difference between the 97 and 95 with 92 brick brick brick material mixed with brine ratio?

- In addition to the brine binder burned magnesia brick and sulfite pulp waste liquid, Magnesium Sulfate solution binder is generally around 3%

- Q: The index of magnesia brick

- Room temperature compressive strength≥(MPa)(15-25-)24.5-24.5-24.5-24.5-40-40-40

- Q: High purity magnesia brick masonry mortar for what?

- You try a mixture of aluminum phosphate. It itself is the main component of aluminum, which can not cause pollution. We use high temperature electric stove to bond with this.But this 800 degree won't be sintered. It won't sinter until more than 1000 degrees.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- The super high alumina brick in high alumina refractory brick has the highest refractoriness, and the corresponding production cost is higher.

- Q: With different capacitance magnesia brick brick

- Fused magnesia brick brick has compact structure, high mechanical strength,It is mainly used for thermal storage of large glass furnaceHigh temperature area of the room.

- Q: Magnesia brick

- General can be divided into sintered magnesia brick (also called burnt magnesia brick) and chemically bonded magnesia brick (also known as the two major categories of not burned magnesia brick). Purity and high firing temperature of magnesia, due to the direct contact of periclase grains, known as direct bonded magnesite brick; made of fused magnesia bricks called electrically fused magnesite brick.

- Q: Process for producing magnesia chrome brick

- The oxide of iron reacts to produce a loose effect caused by the expansion of the spinel. Also, the magnesia chrome brick can be made from the synthetic common sintered material. In addition, there are non burned magnesia chrome bricks, for example, non burned magnesia chrome bricks combined with inorganic magnesium salt solutions. The unfired magnesia chrome brick has the advantages of simple production process, low cost and good thermal stability, but the strength of the high temperature is far less than that of the burnt brick. In the late 50s, a so-called "direct bonding" magnesia chrome brick was developed. The characteristics of this brick raw material is pure, high firing temperature, periclase and spinel phase with high temperature directly, silicate and other low melting point phase for island distribution, therefore, significantly improve the high temperature strength and slag resistance of brick.

- Q: How do you differentiate between the two clearly? Where is the key? Thank you

- Magnesia brick have high refractoriness, alkali slag good performance, high load softening temperature, but poor thermal shock resistance. The sintering magnesia brick brick magnesite as raw material, crushing, proportioning, mixing, forming, in 1550 ~ 1600 degrees firing, high purity products firing temperature is over 1750 DEG C. Don't add chemical bond magnesia brick is appropriate in magnesia, through mixing, molding and drying.

- Q: Magnesite chrome brick, magnesia chrome brick indicators? What is the price?.

- According to the actual situation, design the brick you need, and the price of brick is determined by the index.

- Q: Combined with the ordinary clay brick and magnesia brick as an example, the existence of impurities in minerals and refractories production main components of the formed liquid relative what affect the performance.

- The main varieties of common magnesia brick, magnesia brick, magnesia brick, magnesia brick high pure grade. Product main mineral phase is periclase, volume has high stability and anti erosion ability. Literature is widely used in steelmaking, non-ferrous metal smelting and other high-temperature industrial furnace.

Send your message to us

MGO-C Bricks for Slag Lining of Refining Ladles

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 41000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords