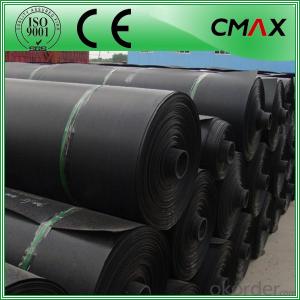

Geotextile Fiber Membrane HDPE Back Pool Liner by Biggest China Factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

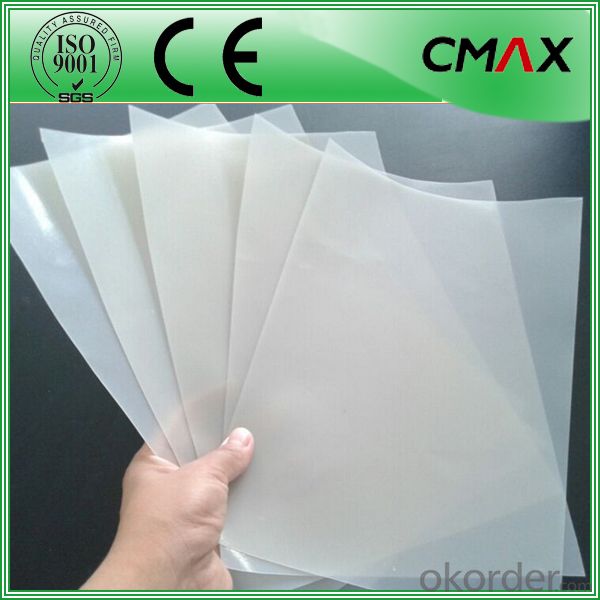

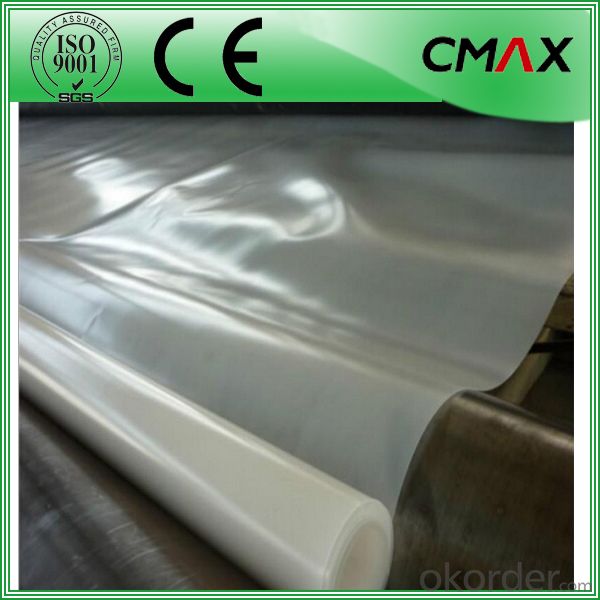

Membrane HDPE Back Pool Liner by Biggest China Factory

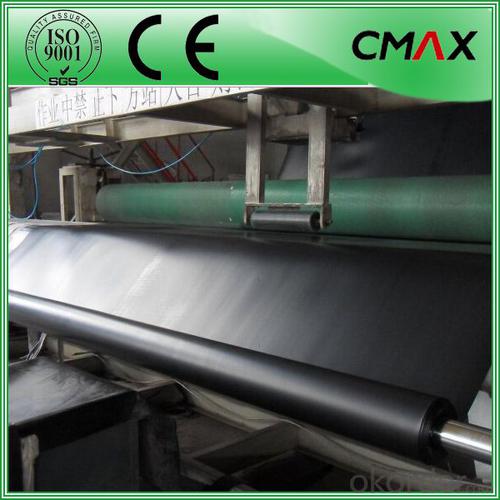

Geomembrane Features:

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

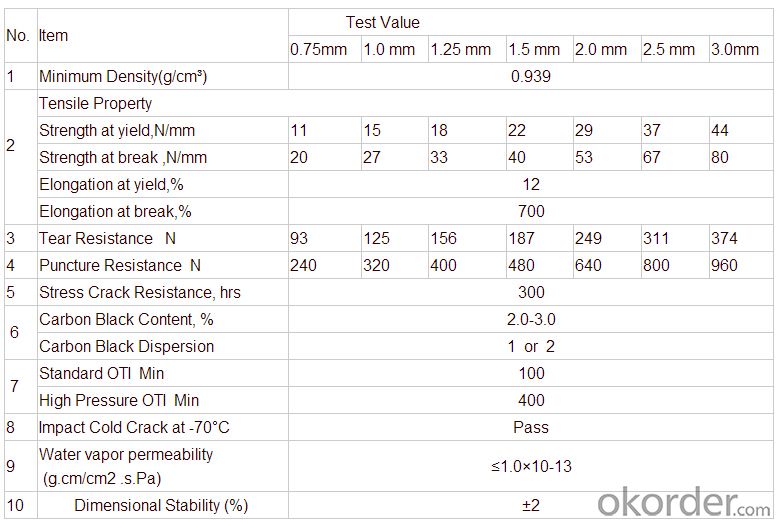

Specifications and Technical datas:

| Thickness | 0.15mm - 4.0mm |

| width | Within 8 m |

| length | 50-100m/roll (at request) |

| Material | HDPE,( LDPE, LLDPE, PVC, EVA ) |

| Color | Black , white , grey |

| Optional surface | Textued(one or two side) or smooth surface |

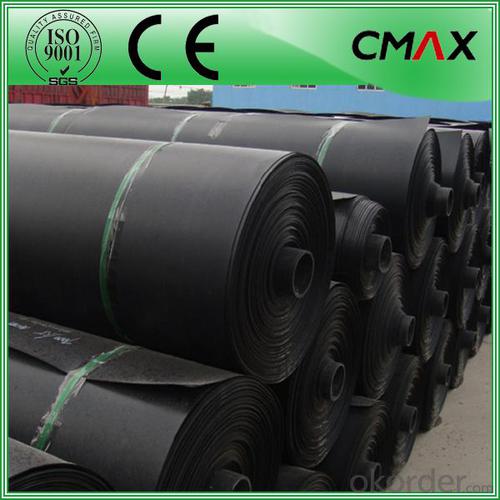

| Manufacturer | The biggest geomembrane liner manufacturer/factory in China for many years |

Details of our products:

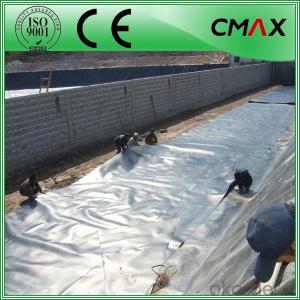

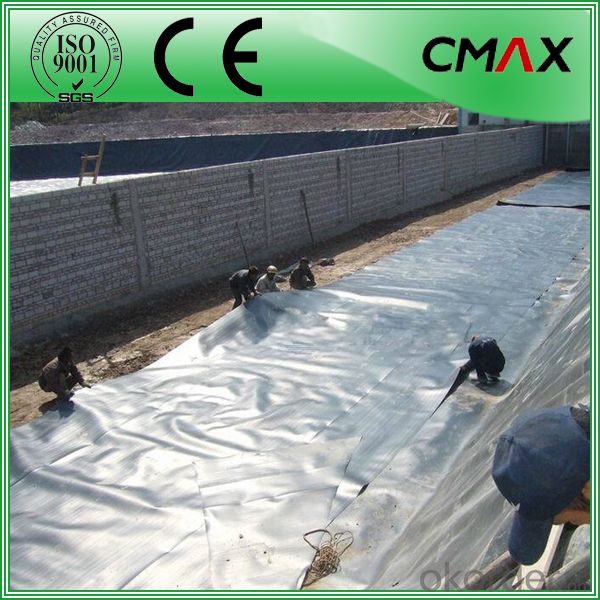

Applications:

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

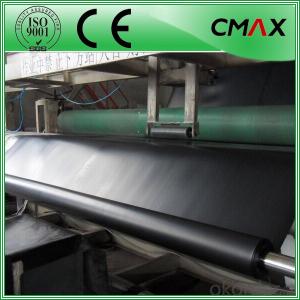

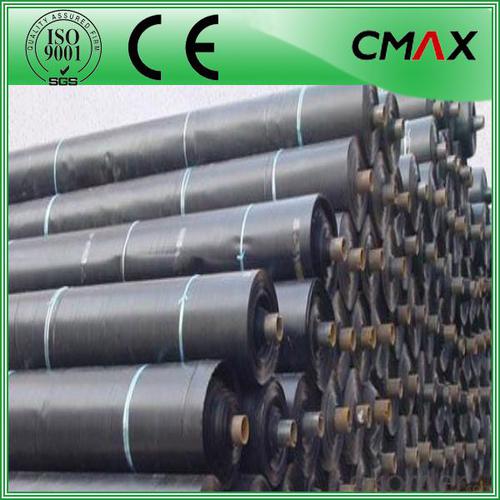

Packing and shipping:

1. The outer package: black or white woven geotextile.or we can make the package as your requst.

2. Different tgram/ roll size for different qty in the same containers.

3. Roll size: 3.95m*200 for container

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What is the geotextile of polypropylene gb / t?

- GB / T-2017 Geosynthetics Static Crack Test (CBR Method) This standard specifies the method of measuring the breaking strength of geosynthetics by flat top pressing bar. This method is usually carried out on samples that specify the standard atmospheric humidity. This standard applies to all types of geosynthetics, but does not apply to materials with a pore size greater than 10mm.

- Q: What are the advantages of using geotextiles in landfill lining systems?

- There are several advantages of using geotextiles in landfill lining systems. Firstly, geotextiles act as a barrier that prevents the migration of contaminants from the landfill into the surrounding environment. This helps to protect groundwater and nearby ecosystems from contamination. Secondly, geotextiles enhance the stability and integrity of the landfill lining system. They provide reinforcement and help to distribute the load evenly, which reduces the risk of structural failure. Additionally, geotextiles have excellent filtration properties. They allow for the efficient drainage of leachate, which is the liquid that is generated as waste decomposes. This helps to prevent the buildup of pressure within the landfill and reduces the risk of leachate seeping into surrounding areas. Furthermore, geotextiles are durable and resistant to degradation, ensuring the longevity of the landfill lining system. They are also lightweight and easy to install, which can save time and costs during construction. Overall, the use of geotextiles in landfill lining systems provides numerous benefits in terms of environmental protection, structural integrity, drainage efficiency, and cost-effectiveness.

- Q: Are geotextiles permeable to water?

- Yes, geotextiles are permeable to water.

- Q: How do geotextiles help with soil reinforcement in retaining wall applications?

- Geotextiles help with soil reinforcement in retaining wall applications by providing a stable base for the wall, preventing soil erosion, and improving the overall stability and durability of the structure. They act as a barrier that separates the backfill soil from the wall, allowing for proper drainage while also preventing the loss of fine particles. This reinforcement helps to distribute the lateral forces exerted by the soil, reducing the pressure on the wall and increasing its overall strength.

- Q: Is the polypropylene composite geotextile and the polyethylene composite geomembrane the same?

- Geotextiles and geomembranes are not the same, but they complement each other to meet the engineering requirements. First introduced under the geotextile: geotextile is the state for civil engineering in the construction of a new type of construction materials, by filament or short fiber through different equipment and process shop into a mesh, and then after acupuncture and other processes to different Fibers are intertwined with each other, tangent to the fabric to make the fabric normal, so that the fabric is soft, plump, thick, stiff, to meet the different thickness to meet the requirements, according to the length of silk is divided into filament non-woven geotextile or short wire Non-woven geotextile, filament tensile strength higher than the short wire. Fibrous soft with a certain tear resistance. The main role is: filter, filter, reinforcement role. Specifications from 100 grams per square meter to 800 grams per square meter. The main material for the polyester fiber, with excellent permeability, filtration, durability deformation adaptability, and has a good flat drainage capacity (see below) Geomembrane to plastic film as anti-seepage substrate, and non-woven composite Made of geotextile impermeable material can be divided into two cloth a film, a cloth a film, its impermeability depends mainly on the plastic film impermeability. The geomembrane is a waterproof barrier material with the polymer of the polymer chemical material as the basic raw material. The proportion of small, strong extension, high adaptability to adapt to deformation, corrosion resistance, low temperature, good frost resistance. (See below)

- Q: Geotextile fng-pet-250-400

- Fng-filament is a polyester filament spunbonded acupuncture non-woven geotextile Cloth 250g / ㎡-400g / ㎡.

- Q: What is the geotextile material?

- Geotextile is made of staple fiber polyester, polypropylene, polyester filament, PP flat silk and other synthetic fibers through acupuncture or weaving made of geotextile, non-woven and industrial non-woven products in one. The general width of 1-6 meters, roll length of 50-100 meters, the quality per unit area of 100-600 grams square meters. According to the different production processes are: polyester / polypropylene staple acupuncture geotextile, PP flat wire woven geotextile, polyester spunbond filament geotextile, single double-sided thermal composite impermeable geotextile, woven geotextile and so on.

- Q: How are geotextiles used in coastal engineering?

- Geotextiles are commonly used in coastal engineering to provide erosion control and stabilization. They are typically used as a layer of fabric or matting beneath coastal structures such as seawalls, revetments, and breakwaters. Geotextiles help to prevent soil erosion, reduce wave energy, and provide stability to the structure. They also allow for water drainage, which helps to prevent hydrostatic pressure buildup and potential damage.

- Q: What are the maintenance requirements for geotextile-reinforced retaining walls?

- The maintenance requirements for geotextile-reinforced retaining walls typically include regular inspections for signs of erosion, damage, or structural issues. Additionally, any vegetation growing near the wall should be monitored and removed if it poses a threat to the integrity of the structure. It is also important to ensure proper drainage and prevent water buildup behind the wall. Regular cleaning and removal of debris is necessary to avoid blockages and maintain the functionality of the drainage system. Overall, following manufacturer guidelines and conducting routine maintenance activities will help ensure the longevity and effectiveness of geotextile-reinforced retaining walls.

- Q: What is the price of composite geotextile?

- Geotextile is divided into polyester short geotextile, staple acupuncture geotextile, polyester filament geotextile, woven geotextile, filament woven geotextile, and so on. Specifications and different models, the price is also different, composite geotextile weight in the 80-1500g / ㎡ between the quality standards are divided into non-standard, whitening A, Sinochem, the general national standard and so on. The t value is generally between 4900 and 7500 yuan / ton, 187 & lt; 6600 & lt; 5604

Send your message to us

Geotextile Fiber Membrane HDPE Back Pool Liner by Biggest China Factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords