Melt Extract Stainless Steel Fiber Straight Type China Company CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

Specifications

Produces shear type, steel wire type, cut type, stainless type, and micro wire type steel fiber. It is used for concret.

SPECIFICATION

TYPE | SIZE | tensile strength |

ENDHOOKED STEEL FIBER | 0.5×0.5×30 mm | 850Mpa min |

0.6×0.7×35 mm | 850Mpa min | |

0.5×0.5×30 mm | 1000MPA min | |

0.6×35 mm | 1000MPA min | |

0.9×60 mm | 1000MPA min | |

CORRUGATED STEEL FIBER | 0.25×0.25×10 mm | 380Mpa min |

0.25×0.25×14 mm | 380Mpa min | |

0.5×0.7×32 mm | 380MPA min |

OTHER SPECIFICATIONS CAN BE DISCUSSED AS PER BUYER’S OPTION

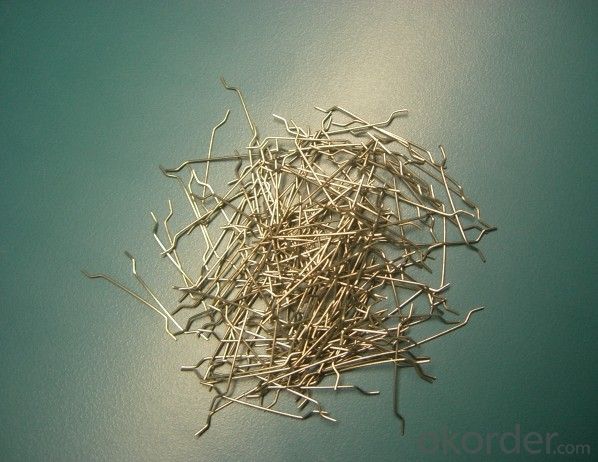

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: Does the addition of melt extract stainless steel fiber affect the workability of concrete?

- Yes, the addition of melt extract stainless steel fiber can affect the workability of concrete. Stainless steel fibers can increase the viscosity and stiffness of the concrete mixture, making it more difficult to work with and requiring additional effort during placement and finishing. However, the exact impact on workability will depend on the dosage and characteristics of the fibers used, as well as the specific concrete mix design.

- Q: Can melt extract stainless steel fiber be used in industrial flooring applications for shotcrete?

- Melt extract stainless steel fiber is a suitable option for shotcrete applications in industrial flooring. Shotcrete is a construction method that involves spraying concrete onto a surface using air pressure, resulting in a fast and efficient way to create a strong and durable floor. By incorporating stainless steel fiber into the shotcrete mix, the overall performance and durability of the flooring system can be enhanced. To produce melt extract stainless steel fiber, stainless steel is melted and then rapidly extracted into fine fibers. These fibers are known for their high tensile strength, resistance to corrosion, and toughness. When added to shotcrete, they contribute to improved crack resistance, impact resistance, and overall durability of the floor. In industrial environments where floors are subjected to heavy loads, impacts, and abrasion, using stainless steel fiber in shotcrete can offer significant advantages. It helps to minimize cracking, enhance resistance to wear and tear, and extend the lifespan of the floor. Moreover, stainless steel fiber can augment the fire resistance of shotcrete flooring, making it appropriate for industrial settings where fire safety is a concern. Overall, melt extract stainless steel fiber is an excellent choice for shotcrete applications in industrial flooring. It provides enhanced performance, durability, and fire resistance, making it a dependable solution for industrial settings that require robust and long-lasting flooring.

- Q: What is the effect of melt extract stainless steel fiber on the impact resistance of concrete?

- The impact resistance of concrete is positively affected by the inclusion of melt extract stainless steel fibers. When these fibers are added to the concrete mix, they enhance the material's tensile strength and ductility, thereby increasing its resistance to impact and cracking. Acting as reinforcement, the fibers distribute the energy from an impact event throughout the concrete matrix, reducing stress concentration and preventing crack formation. Furthermore, the stainless steel composition of the fibers provides corrosion resistance, ensuring the long-term durability of the concrete structure. Overall, the addition of melt extract stainless steel fibers significantly improves concrete's impact resistance, making it a suitable choice for applications where heavy loads or potential impact events are anticipated.

- Q: What is the effect of melt extract stainless steel fiber on the modulus of plasticity of concrete?

- Adding melt extract stainless steel fibers to concrete enhances its modulus of plasticity, boosting overall flexural strength and ductility. These fibers strengthen the concrete and enable it to withstand bending forces without fracturing. The presence of these fibers in the concrete matrix evenly distributes the load, preventing crack formation and propagation. This improves the modulus of plasticity, which refers to the material's ability to deform under stress without permanent deformation or failure. By increasing the modulus of plasticity, melt extract stainless steel fibers contribute to a more durable and resilient concrete structure. Moreover, these fibers improve the post-cracking behavior of concrete. Even after the concrete cracks under load, the stainless steel fibers hold the cracked sections together, limiting further crack propagation. This enhances the concrete's performance by increasing its resistance to fatigue and reducing the potential for sudden failure. In conclusion, incorporating melt extract stainless steel fibers in concrete positively impacts the modulus of plasticity by enhancing flexural strength, ductility, and crack resistance. This results in a more resilient and durable concrete structure that can handle higher loads, reducing maintenance needs and extending the lifespan of the construction project.

- Q: What is the effect of melt extract stainless steel fiber on the thermal conductivity of concrete?

- The thermal conductivity of concrete can be greatly improved by incorporating melt extract stainless steel fiber. Stainless steel fibers possess excellent thermal conductivity properties, enabling them to effectively transfer heat throughout the concrete. When these fibers are added to the concrete mixture, they create a three-dimensional network that aids in the efficient conduction and distribution of heat. This enhanced thermal conductivity has multiple positive impacts on the performance of the concrete. To begin with, the heightened thermal conductivity can enhance the overall thermal efficiency of structures constructed with this particular type of concrete. It facilitates better heat transfer, leading to more efficient temperature regulation and reducing the need for additional insulation or heating and cooling systems. Furthermore, the improved thermal conductivity can also enhance the durability of the concrete. By evenly distributing heat and minimizing temperature variations, the risk of thermal cracking and damage due to expansion and contraction is diminished. This is particularly advantageous in environments with substantial temperature fluctuations. Moreover, the greater thermal conductivity provided by melt extract stainless steel fiber can also be beneficial in applications like radiant floor heating systems. The fibers effectively transfer heat from the heating elements to the surface, resulting in more efficient and effective heating. In conclusion, the incorporation of melt extract stainless steel fiber in concrete significantly improves its thermal conductivity. This improvement leads to increased thermal efficiency, enhanced durability, and improved performance in various applications where heat transfer is crucial.

- Q: Can melt extract stainless steel fiber be used in pedestrian walkway pavements?

- Melt extract stainless steel fiber is a suitable option for pedestrian walkway pavements. Concrete mixtures are frequently enriched with stainless steel fibers to enhance their mechanical properties and overall performance. By incorporating stainless steel fibers, the concrete's tensile strength and resistance to cracking are increased, resulting in improved durability and suitability for high-traffic areas such as pedestrian walkways. Moreover, the utilization of stainless steel fibers offers better corrosion resistance and aids in preventing crack formation due to temperature fluctuations or shrinkage. Consequently, melt extract stainless steel fiber is an exceptional choice for reinforcing pedestrian walkway pavements, guaranteeing their longevity and safety.

- Q: The steel fiber concrete cover per cubic concrete how much steel fiber

- You can ask them, too, without knowing whether their equipment will be the same.

- Q: How does melt extract stainless steel fiber affect the rheology of self-compacting shotcrete?

- Melt extract stainless steel fiber can have a significant impact on the rheology of self-compacting shotcrete. Firstly, the addition of stainless steel fibers can improve the overall viscosity and fluidity of the shotcrete mix. The fibers act as a reinforcement and help to maintain the stability and flowability of the mix, preventing segregation and settlement during application. This is particularly important in self-compacting shotcrete, where a high degree of workability is required to ensure proper consolidation and filling of the desired areas. Moreover, the stainless steel fibers also enhance the cohesion and cohesiveness of the shotcrete mix. The fibers act as a bonding agent, improving the interparticle interactions and increasing the overall strength and durability of the shotcrete. This results in a more cohesive and stable material that is less prone to cracking and shrinkage. Additionally, the presence of stainless steel fibers can also impact the setting time of the shotcrete. The fibers can accelerate the hydration process and promote the early development of strength. This is beneficial in self-compacting shotcrete applications where rapid setting and early strength development are desired to allow for faster construction progress. Furthermore, the melt extract stainless steel fibers can also contribute to the overall ductility and toughness of the shotcrete. The fibers provide additional resistance against crack propagation and enhance the overall structural integrity of the material. This is crucial in self-compacting shotcrete, as it allows for better performance under dynamic loading conditions and enhances the ability of the material to withstand external forces. Overall, the melt extract stainless steel fibers have a positive effect on the rheology of self-compacting shotcrete by improving viscosity, cohesion, setting time, and overall durability. Their addition enhances the workability and performance of the shotcrete, making it a highly suitable material for various construction applications.

- Q: What are the advantages of melt extract stainless steel fiber over other types of steel fibers?

- Melt extract stainless steel fibers provide numerous benefits compared to other varieties of steel fibers. To begin with, the corrosion resistance of melt extract stainless steel fibers is exceptional. The fibers contain a significant amount of chromium, which produces a protective oxide layer on their surface. This layer acts as a barrier against corrosive elements, ensuring high resistance to rust and deterioration. This advantage is particularly crucial in environments where exposure to moisture, chemicals, or elevated temperatures is common. Furthermore, the mechanical properties of melt extract stainless steel fibers surpass those of other steel fibers. These fibers are manufactured by melting the steel and subsequently rapidly extracting it into fine filaments. This process results in fibers with a high tensile strength, enabling them to withstand heavy loads and resist deformation under stress. This strength also enhances the durability and lifespan of structures reinforced with melt extract stainless steel fibers. Moreover, melt extract stainless steel fibers possess a high melting point, rendering them suitable for use in high-temperature applications. These fibers can endure extreme heat without compromising their structural integrity, making them ideal for reinforcing concrete in settings such as industrial furnaces, fire-resistant structures, and thermal power plants. Additionally, the fine and uniform nature of melt extract stainless steel fibers allows for better dispersion throughout the concrete matrix. This leads to enhanced crack resistance and improved load-bearing capacity of the reinforced concrete. The small diameter of these fibers also facilitates superior bonding with the surrounding concrete, resulting in increased bond strength and overall structural performance. Finally, melt extract stainless steel fibers exhibit excellent electrical conductivity. This makes them appropriate for applications requiring electrical grounding or conductivity, like electromagnetic shielding or structures exposed to electrical currents. In conclusion, melt extract stainless steel fibers offer a multitude of advantages, including superior corrosion resistance, high mechanical strength, resistance to high temperatures, improved crack resistance, enhanced bond strength, and excellent electrical conductivity. These factors establish them as the preferred choice over other steel fibers for a wide range of applications in the construction, infrastructure, and industrial sectors.

- Q: Is melt extract stainless steel fiber suitable for use in airport runway construction?

- Melt extract stainless steel fiber is indeed a suitable option for airport runway construction. Its durability, corrosion resistance, and high tensile strength make it perfect for heavy-duty applications such as airport runways. By incorporating these fibers into the concrete, the overall strength and performance of the material are enhanced, resulting in improved resistance to cracking, impact, and fatigue. Moreover, the non-magnetic properties of stainless steel fibers are crucial for airport runways, as they ensure there is no interference with sensitive navigation systems. Hence, choosing melt extract stainless steel fiber is a dependable and fitting decision for constructing airport runways.

Send your message to us

Melt Extract Stainless Steel Fiber Straight Type China Company CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords