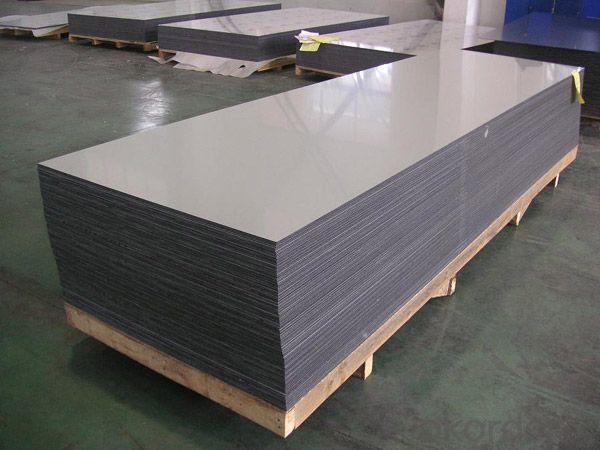

Material For Wall Fire Rated Aluminum Composite Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Material For Wall Fire Rated Aluminum Composite Panel

1. Standard:

according to GB/T 17748-1999 standard

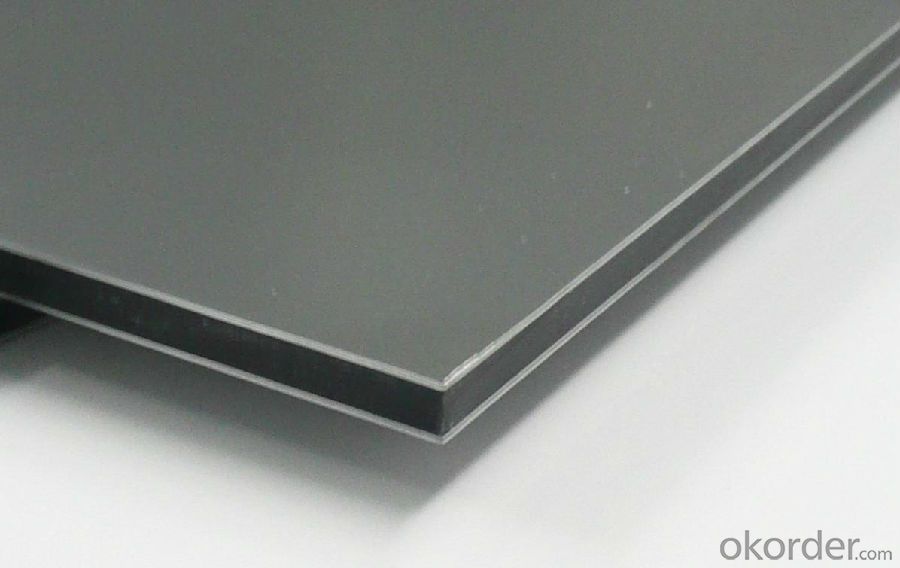

2. Material:

a) Front: aluminum alloy sheet coated with fluoro-carbon resin

(PVDF) and polyester resin (PE) roasting painting

b) Core: nontoxic polyethylene.

c) Back: aluminum alloy sheet coated with polyester resin painting

d) Surface finish: treated with PVDF and PE resin rolling roasting .

coating

e) Surface coating thickness: 30um

f ) Aluminum alloy sheet thickness: 0.1mm, 0.12mm, 0.15mm, 0.2mm,

0.3mm, 0.4mm, 0.45mm, 0.5mm

3. Dimensions:

a) Thickness: 3mm, 4mm

b) Width: 1220mm 1500mm..

c) Length: 2440mm, 3200mm, 4000mm,5000mm (max: 6 meter)

d) Weight: 5.5kg/sqm based on 4mm thickness.

e) Standard size: 1220 x 2440mm

f) Nonstandard sizes are available according to requirement of customers

4. Application scope:

1) Building exterior curtain walls..

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decorations

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels..

7) Industrial materials, materials for vehicles and boats

Production Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Coating line | WANGUAN | 2 | 4.5 | Acceptable |

| Aluminum plastic composite line | FB1600 | 4 | 3.5 | Acceptable |

| Embossing line | No information | 1 | 1.0 | Acceptable |

Testing Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Bending machine | No information | 1 | 8.0 | Acceptable |

| Visual comparison of the colour device | MSBS-1 | 1 | 5.0 | Acceptable |

| Drying oven | PULUO | 1 | 5.0 | Acceptable |

- Q: New house I would like to all use aluminum-plastic panels such as kitchen, door, edge line, cut off. Do not know whether or not, the specific price of how much, there is no pollution, decoration costs are generally much. Thank you!

- Can not use aluminum-plastic plate because aluminum-plastic plate for a long time, will be oxidized, the appearance does not look good.

- Q: Company decoration use, I would like to ask the center line of well-known brand of aluminum slab board, aluminum plate which brand? What is the price?

- Good point with Huayuan, Haida. Colorful. (Good point of the three main for the engineering board and export single retail not much)

- Q: Aluminum-plastic plate pillars, slot depth and the tip of what is the relationship

- No direct relationship - depth is artificially adjustable! The style of the tip is related to the requirements of the slot - there are V, U and other shapes

- Q: Aluminum veneer and aluminum sheathed which fire?

- No fire under the fire!

- Q: Aluminum-plastic board dirty what cleaning

- can not use gasoline, xylene, banana water and other organic solvents, because the organic solvent will destroy the beauty of aluminum-plastic plate, affecting the service life.

- Q: Dear brothers and sisters please tell the little sister What are the manufacturers of aluminum-plastic factory in Guangzhou I need the name of the factory hurry!

- Guangzhou Guangfeng Decoration Materials Co., Ltd

- Q: What is the aluminum plate and what features

- Aluminum-plastic plate, in fact, is the abbreviation of aluminum-plastic composite panels. Aluminum-plastic composite panel is made of aluminum alloy plate on both sides of the inside and outside, low-density polyethylene core layer and adhesive composite as one of the light wall decoration materials. As a new type of building materials, aluminum-plastic panels are widely used in building exterior decoration, signs, display panels, advertising boards, building partitions, interior wall decorative panels.

- Q: Will the aluminum on the aluminum plate is thick aluminum out of 10% -50% between now do not have a syrup, direct separation of the equipment where to sell

- There is no only to pay back the station as long as the control of the temperature can be separated as if in the development of ah and so on ah

- Q: Imitation aluminum-plastic plate of the glass curtain wall, is a high-level curtain wall? What is the name and process?

- When the aluminum-plastic plate to imitate the glass, the choice of gloss and bright texture to imitation, so the current window of the future of aluminum-plastic manufacturers to introduce high-gloss aluminum-plastic plate is so born.

- Q: Which company can print the production of large snow Fu board, iron, aluminum, aluminum-plastic plate billboards?

- OKorder Shengzhi Government Printing Co., Ltd. can print large-scale Chevette board, iron plate, aluminum plate, aluminum-plastic plate billboards, their prices are very cheap, many well-known world 500 companies are looking for their printing products, they are the only OKorder A large and small screen printing machine manufacturers, can print 2 * 4 meters of products. I was a trading company in Ningbo, I began to print a number of them in the aluminum-plastic plate billboards, they helped me print out the best results, their company's gold learns forever is a business and technology is very professional people, I made a reasonable proposal for the use of materials and technology, to meet the quality requirements of our foreign customers at the same time also saved me the cost and increased our company's profit margins, so I have a screen printing orders are very willing to find OKorder Sheng Zhicheng Government do.

Send your message to us

Material For Wall Fire Rated Aluminum Composite Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords