Matching Mixing Plant Construction Machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Matching Mixing Plant Construction Machinery

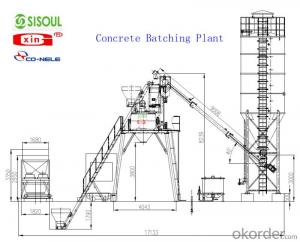

BRIEF INTRODUCTION

Theory productivity 75 m3/h Matching mixer JS1500

Discharging height 3.8 m Aggregate metering precision ±2%

Cement weighing precision ±1% Water weighing precision ±1%

Additive weighing precision ±1%

Control room 6 m2 Aggregate hopper volume 15m³×4

Cement silo: 100t (optional) Cement screw conveyor: Ф219 (optional)

Floor area 30m×12m Total power: about 105 kW(Not including screw conveyor)

Gross weight :33 tons(not including screw conveyor and cement silo)

PART III: TECHNICAL DATA

Item | Specification |

1 | Aggregate Supply System is composed of aggregate bin, frame, weighing hopper, aggregate conveyer and sensors. 1、 Aggregate bin ⑴ Volume: 15m3×4 ⑵ The feeder: 8 ⑶ Cylinder: bore 100 stroke 300 (with solenoid valve) 8 pieces 2、 Weighing hopper: ⑴ Volume: 5000L ⑵ Measure mode: measure together ⑶ Sensor: STL-2000 qty: 4 Amcell America ⑷ Measuring precision: ±2% 3、 Belt conveyor with cleaner ⑴ Belt specification: 650mm ⑵ Belt speed 4. Driven drum:CG-φ320*750Z Electric power: 7.5kW 5. Vibrator: MVE200/3 Oli-wolong Power: 0.15kW 4 sets |

2 | The elevating system 1) Electric Windlass: Power: 22kW 2) Convey capacity: 2400L 3) No Temporary storage hopper 4) Discharging material gas cylinder: 5) Windlass engine: XWN39-17-22 |

3 | Mixing System Model: JS1500/Twin-shafts horizontal forced type Charging volume: 2400 L Discharging volume: 1500 L Discharging height: 3.8m Motor power: 30kW×2 Mixing blade、 lining board: wear resistance material System instruction: Planetary gear reducer, small volume,high efficiency,high reliability. Lining board and material of blade are chrome wear-resisting cast iron, reasonable design of angle and quality mixing efficiency,quick speed and long service life. Discharging gate is controlled by hydraulic oil pump. There are three stick points and no noise. Overweight design and good damping |

4 | Mixing Platform Discharge height 3.8m Mixing platform electromagnetism valve Stairway, platform, handrails |

5 | Cement weighing system Cement weighing system is composed of cement weighing hopper, pneumatic butterfly valve, sensors and so on. Cement weighing system Volume: 700L Weighing range: 0~700 kg Weighing precision: ±1% Sensor: SSB-Ⅲ-500 Qty.: 3 Amcell America Pneumatic butterfly valve: BV1F300S Vibrator MVE100/3 Oli-wolong Power: 0.09kW |

6 | Water weighing system Water weighing system is composed of pool (made by customer themselves), water pump, pneumatic butterfly valve and so on. Volume: 500L water supply pump: QY50-18-4kW Pipe pneumatic ball valve Discharging pneumatic butterfly valve Weighing precision: ±1% |

7 | Additive weighing system including the box and pipeline Liquid additive weighing system is composed of additive storage box, additive weighing hopper, pneumatic butterfly valve and sensor and so on. 1.Additive supplying pump power: GISG25-125-0.75KW 2. Pneumatic three way ball valve 3. Additive storage box: 2 m3 4. Weighing precision: ±1% 5. Weighing hopper pneumatic butterfly Volume: 40L

|

8 | Pneumatic system is composed of air compressor, gas cylinder, electromagnetic and pneumatic components. 1) Air compressor: power: 11kW 2) Electromagnetic: a) Main tower electromagnetic valve of pneumatic control case b) Cylinder electromagnetic valve c) Cement break electromagnetic valve quantity is same as powder storage 3) Air supply disposal components |

9 | Control System 1. The operation is integrated with management .It is easy and convenient to operate. 2.The batching system is controlled by the microcomputer. 3.The operating data of the mixing plant can be saved for more than ten years for the convenience of setting management. 4.The formula which can reach more then dozens can express by the figures for the convenience of distinguishing. 5. It has the function of error analysis and automatic checking. 6. Under the condition departing from the automatic control .The manual operating system can finish the control of the mixing plant such as batching, mixing discharging. 7. The heavy-current part of the system is separated from the weak-current part, so it enhances the ability of anti-jamming. Easy to maintain. 8. Equip with printer 9. Equip with air-condition 10.Control room: 6m2 System instruction: The main hardware of this system adopts Germany Siemens products with advanced performance, high reliability and beautiful exterior. Console adopts man-machine engineering design, comfortable operation. |

12 | Screw conveyor (optional) 1. Model:∮219 2. Conveying capacity: 45t/h 3. Power: 11KW 4. Quantity: ∮219 |

13 | Cement silo (optional) 1. Model: Piece type easy to load and transport 2. Capacity: 100t Quantity:1 units |

We have the following services:

1. installation, debugging, operators trainning;

2. maintanence:

A. when trainning your operators, our engineers will give them advice on how to operate the machines correctly;

B. we will send you the operation manual which can help you operate the machins properly, it can also help you to solve

the common problems;

C. Call us at any time if you have problems about our concrete plants;

D. If needed, we will send engineers to your site to solve your problems.

3. providing documents needed for your customs clearance, like commercial invoice, packing list, certificate of origin etc;

4. spare parts supply;

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Concrete Machinery according to customersrequest?

A4: Yes, we can produce Concrete Machinery according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

- Q: What is the concrete of the mixing station?

- Concrete mixing stations are made of concrete, which is made of concrete for various construction sites, including commercial housing, concrete floor, industrial workshop and so on.

- Q: Cement warehouse introduction, storage reserves?

- Cement silo in concrete mixing plant is mainly used for the storage of bulk cement, there are usually used 80 t, 100 t, 120 t, 150 t, etc., this is according to the size of the concrete mixing station or the user's production decision.

- Q: How much concrete is produced per hour by HZS180 concrete mixer?

- HZS180 concrete production line equipment production line equipment per hour theory produces 180 cubic concrete. It depends on the equipment situation. Henan zheng a heavy industrial concrete mixing plant equipment factory

- Q: How much water does a concrete mixer use every day?

- It is also a waste of water to flush the transports. Suppose you flush a vehicle with 1-2t water, rinse it 2-3 times a day, and use 20 cars a day for a medium size of a blender, 40 to 120 t a day. From this perspective, the reuse of washing water is very conducive to environmental protection and water conservation. The rational recycling of water in the mixing stations is also gradually being promoted. Our new hydraulic patent product concrete wastewater and sewage circulation recycling used by many domestic manufacturers, most of new mixing plant began to use the recycling equipment. The wastewater recovery system has made some efforts for the environmental cause of China.

- Q: What constitutes the js750 concrete mixing station

- Host one, silo (usually four kinds of material), a set of mainframes, three to four storage tanks (with a cage), and an air compressor, which is usually the case

- Q: What does HZS mean in the HZS120 concrete mixing station

- Because building aggregate measurement compared with standing aggregate metering, reduced the four of the intermediate links, and the vertical blanking metering, saved measuring time, thus greatly improving the production efficiency, under the condition of the same model, mixing building production efficiency than mixing plant production efficiency by a third. Such as: HLS90 floor of production efficiency and production efficiency of HZS120 stand HLS120 floor of production efficiency, production efficiency is equivalent to HZS180 stand HLS180 floor of the production efficiency is equivalent to the productivity of HZS240 station.

- Q: What are the advantages of HZS series of concrete mixing stations

- HZS75 concrete batching plant investment amount, less occupied area is small, the use of equipment, maintenance easy, can be equipped with high performance of independent control room, make the equipment operation convenient and safe, and in the batching machine also can produce high quality under the condition of accurate measurement of concrete. This type of mixing station under our positive study also used the green environmental protection design, the construction of a possible pollution under control, rather than the old way of construction and transportation pollution, nature is winning.

- Q: How much concrete is produced by the js1000 type of the concrete mixing station

- The production standard test concrete is not less than 50 cubic meters per hour. But the actual situation is (fully automatic), usually more than 40 cubic meters per hour. The cement productivity would be low by hand. Concrete mixing station, also known as concrete mixing station, concrete mixing station is mainly composed of mixing console, materials weighing system, conveying system, material storage system and control system and so on five big systems and other ancillary facilities. Because building aggregate measurement compared with standing aggregate metering, reduced the four of the intermediate links, and the vertical blanking metering, saved measuring time, thus greatly improving the production efficiency, under the condition of the same model, mixing building production efficiency than mixing plant production efficiency by a third. Concrete mixing station is mainly composed of material storage system, materials weighing system, material conveying system, mixing console and electric control system and other ancillary facilities. The mixing and electrical control system is a key part of the whole equipment.

- Q: Concrete mixstations belong to no special equipment

- Is not mixing station is places or facilities, equipment, for whether the equipment belongs to the special equipment to check the catalog of special equipment, included in the directory is the special equipment, is not included.

- Q: The mixing time of the concrete mixer is in which standard

- Concrete quality control standard gb50164-2011

Send your message to us

Matching Mixing Plant Construction Machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords