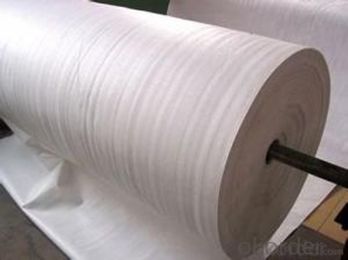

Malla Geotextil Para Que Sirve - High Quality Polypropylene Nonwoven Fabric Geotextile Price Per M2 for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

1:Use of polyester staple fiber nonwoven fabric with different physical properties (particle size, distribution, consistency and density, etc.) of the building materials (such as soil and sand, soil and concrete, etc.) in isolation. Make no loss between two or more materials, not mixed, maintains the whole structure and function of material, to reinforce structure load bearing capacity.

2: Filter

When water flows into coarse material composed of fine soil soil layer, the use of polyester staple fiber geotextile acupuncture good air permeability and water permeability, make the water flow through, and effectively current-carrying soil particles, sand, small stones, etc., to maintain the stability of soil and water conservation project.

3: drainage

Polyester staple fiber geotextile acupuncture has good conductivity performance, it can be formed within soil drainage channel, excess liquid and gas discharge of the soil structure.

NO.Specifications and indicators100150200250300350400450500600800Remark

1Deviation of mass per unit area2)(%)-8-8-8-8-7-7-7-7-6-6-6

2Thickness (mm≥)0.91.31.72.12.42.733.33.64.15

3Amplitude-deviation(%)-0.5

4Breaking strength(KN/m≥)2.54.56.589.51112.514161925LD/MD

5Elongation at break(%)25-100

LD/MD

6CBR burst strength(KN≥)0.30.60.91.21.51.82.12.42.73.24

7Equivalent aperture090(095)(mm)0.07-0.2

8Vertical permeability coefficient(cm/s)K×(10-1-10-3)K=1.0-9.9

9Tearing strength(KN≥)0.080.120.160.20.240.280.330.380.420.460.6LD/MD

Note: TD=transverse direction LD=longitudinal direction

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Highway on the highway geotextile laying program who has ah?

- The specific construction program, ah, that depends on your specific project, but generally there is such a Hongxiang professional construction staff introduction We usually in the highway geotextile before the laying of the first sprinkle asphalt sticky oil, the amount of about 0.4 ~ 0.6kg / ㎡, and then shop geotextile, and then sprinkle a layer of geotextile in the same type of sticky oil, the amount of about 0.5 ~ 0.6kg / ㎡, also need to pay attention to the temperature when the contact. Geotextile laying before laying a layer of asphalt is to better play the role of anti-seepage, geotextile to adapt to the contact with the asphalt and other materials when the temperature, requiring a higher melting point. The asphalt impregnated geotextile into spray asphalt combined with oil, the geotextile firmly rolled in the above and then spray a thin layer of asphalt, increase the adhesion of the opposite layer, improve water resistance. If the use of paver laying asphalt concrete surface layer, can not spray surface layer of asphalt, only in the bottom to increase the amount of asphalt, control in 1000g / m2 or so. After rolling, the asphalt through its pores through the geotextile reverse osmosis to the surface layer, forming a sealed waterproof layer, but also play a role in reinforcement, improve the new layer of anti-fatigue performance. It is economical and durable.

- Q: The difference between short wire geotextile and filament geotextile

- Geotextile is a collectively, he includes filament geotextile, short wire geotextile, woven geotextile, woven geotextile, hot pressed nonwovens. Polyester filament geotextile color is mainly white, green. Gray two categories. The length of the fiber is greater than 4.5 cm. Strong strength is very high. Looks very good distinction.

- Q: How do geotextiles help in reducing soil erosion caused by wind?

- Geotextiles help in reducing soil erosion caused by wind by acting as a barrier that prevents the soil particles from being carried away. They are commonly used as a protective layer on slopes or exposed areas, where they effectively stabilize the soil and prevent it from being blown away by wind. Additionally, geotextiles also help in promoting vegetation growth by retaining moisture and providing a favorable environment for plant root development, further strengthening the soil and reducing erosion.

- Q: Are geotextiles cost-effective?

- Yes, geotextiles are cost-effective. They offer numerous benefits such as erosion control, soil stabilization, and filtration, which can reduce the need for expensive repairs or replacements of infrastructure. Additionally, geotextiles are typically easy to install and require minimal maintenance, further contributing to their cost-effectiveness.

- Q: What are the key factors affecting the filtration performance of geotextiles?

- The key factors affecting the filtration performance of geotextiles include the permeability of the geotextile, the pore size distribution, the thickness and weight of the geotextile, the hydraulic gradient, and the particle size of the soil being filtered.

- Q: Can geotextiles be used in coastal erosion control?

- Yes, geotextiles can be used in coastal erosion control. They are often used in the construction of coastal structures such as groins, revetments, and seawalls to stabilize the soil and prevent erosion. Geotextiles help to reinforce the structural integrity of these coastal defenses, while also allowing water to drain through and reduce wave energy. Additionally, they can be used in beach nourishment projects to retain sand and prevent its loss due to wave action. Overall, geotextiles are an effective tool in mitigating coastal erosion and protecting shorelines.

- Q: Are geotextiles suitable for use in erosion control mats for revegetation?

- Yes, geotextiles are suitable for use in erosion control mats for revegetation. Geotextiles are designed to stabilize soil and prevent erosion by providing a barrier against water and wind. They also promote vegetation growth by allowing water and nutrients to penetrate the soil while protecting the roots from erosion. Overall, geotextiles can be an effective solution for erosion control in revegetation projects.

- Q: Measured geotextile vertical permeability, "highway engineering geosynthetics test procedures" T1141-2006 6.3 balanced head difference is not necessary to balance the 50mm? Can not balance ah more

- So deep, although we produce geotextile, but geotextile detection really is not proficient in it

- Q: Can geotextiles be used in the construction of artificial islands?

- Yes, geotextiles can be used in the construction of artificial islands. Geotextiles are commonly used in civil engineering projects for their ability to provide soil stabilization, erosion control, and drainage. In the construction of artificial islands, geotextiles can be used as a barrier to prevent soil erosion, reinforce embankments, and promote the establishment of vegetation. They can also help with filtration and separation of different materials during the island building process.

- Q: What are the considerations for geotextile selection in coastal engineering projects?

- There are several important considerations for geotextile selection in coastal engineering projects. Firstly, the geotextile should possess high tensile strength and durability to withstand the harsh coastal environment, including waves, tides, and erosion. It should also have good permeability to allow for proper water drainage while preventing the loss of soil particles. Additionally, the geotextile should be resistant to UV degradation and chemical exposure, as well as be compatible with the surrounding soil and other materials used in the project. Lastly, factors such as installation ease, cost-effectiveness, and the specific requirements of the project should also be taken into account when selecting the appropriate geotextile for coastal engineering projects.

Send your message to us

Malla Geotextil Para Que Sirve - High Quality Polypropylene Nonwoven Fabric Geotextile Price Per M2 for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords