Magnesium Plate Hardox400 Plate Printing Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Application of Magnesium Plate Hardox400 Plate Printing Plate:

- Aerospace, defense and satellite applications where weight reduction is critical

- Electronic components where shock absorbing qualities are crucial

- Automotive/Motor sports applications where weight reduction and strength are required

- Mechanical vibration shakers for test fixtures

2.Advantage of Magnesium Plate Hardox400 Plate Printing Plate:

- Magnesium is the lightest industrial metal in the world

- One third lighter than aluminum

- Magnesium is as strong as aluminum

- Magnesium is shock absorbing and dampens vibrations

- Magnesium is very machinable

3.Mechanical Property of Magnesium Plate Hardox400 Plate Printing Plate:

Positive CTP Plates | |

1. ISO9001:2000 | |

2. Long press time | |

3. High quality | |

4. For commercial printing and news paper printing | |

Surface treatment | Use the fine aluminum substrate with electro chemically graining, anodized oxidization, and hydrophilic treatment |

Spectral sensitivity | 800-850nm,Max:830nm |

Exposure quantity | 120-150mj/cm2 |

Resolution Power | 1-99%@450lpi |

Run length | Before baking: 100,000+ |

After baking: 300,000+ | |

UV ink applicability | Can be used after baking |

Baking condition | 230-250℃,5-8min(With recommended CTP baking solution) |

Size | Maximum size of short side: 1450mm |

Diagonal cutting tolerances: ≤0.5mm | |

Storing condition | Away from light and heat,keep in dry and cool place |

The recommended condition | Temp: 5-30 ℃,RH:40-80% |

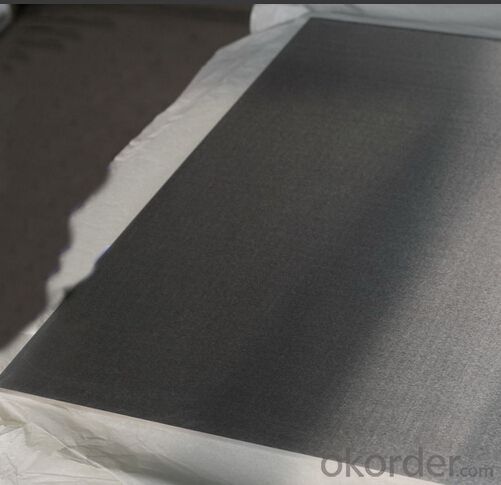

4.Picture of Magnesium Plate Hardox400 Plate Printing Plate:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What is called cemented carbide?

- Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness. Hard alloy are widely used as tool materials. Such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials. Hundreds of times now cutting speed of new carbide tool is carbon steel.Carbide can also be used to make rock drilling tools, mining tools, drilling tools, measuring tools, wear-resistant parts, metal abrasives, cylinder liner, precision bearings, nozzles and so onIn the past twenty years, coated carbide also come out in Sweden.1969 in the successful development of titanium carbide coated tools, the tool is a matrix of tungsten carbide titanium carbide cobalt alloy or cobalt tungsten carbide, titanium carbide surface coating thickness of only a few microns, but with the same grade alloy tool compared to prolong the service life of 3 times, cutting to increase the speed of 25% ~ 50%.20 in 70s has been fourth generation coating tools, can be used for cutting hard processing materials.

- Q: What is the difference between hard alloy and steel

- Cobalt (Co) is used in bonding in the alloy, is in the process of sintering, it can make the tungsten carbide (WC) powder and tightly surrounded Bonded together, after cooling, became hard alloy. (equivalent to the cement content). Usually: 3%--30% tungsten carbide (WC) is the main component of some metal properties of the hard alloy or cermet, the total composition of 70%---97% (weight ratio) is widely used in wear-resistant, high temperature resistance, resistance corrosion, bad working environment of the parts or tool, cutter tools.

- Q: Carbide coated drill bit will reduce the service life after grinding, how to avoid?

- Sure, the grinding efficiency of the drill can reach about 80% of the new drill. Of course, the repair should be professional, experienced manufacturers repair oh. We can drill hard alloy coated drill bit to ensure quality.

- Q: How many models are there? 10Because we want to purchase carbide milling cutters, we would like to know the classification methods and the characteristics of various types of carbide at home.Some people say that Zhuzhou is best, Nanchang, Fujian, Longyan in turn. But there are many factories in a region. How can you say which is good and that is not good?Do you have a YL model?

- Overall, Zhuzhou cemented carbide works, Shanghai alloy materials factory, Zigong cemented carbide plant, new carbide knives are good. But the single pair of milling cutters is not clear! There is no YL!

- Q: High end markets for cemented carbides

- The high-speed steel cutting tools are being reduced by 1% to 2% annually, and the proportion has been reduced to less than 30%.At the same time, the hard alloy cutting tools in China has become the main tool required for processing enterprises, is widely used in the production of auto parts, mold manufacturing, aerospace and other industrial fields, but our tool enterprises blindly, but a large amount of production of high speed steel and some low-grade standard tools, with no consideration the saturation of the market and enterprises need to end with high value-added, high-tech high-end tool market "over" to foreign enterprises.The data shows, our tool has annual sales of approximately 14 billion 500 million yuan, of which the proportion of hard alloy cutter is less than 25%, more than carbide tool but domestic manufacturing industry has occupied the required tool 50%, the blind production has serious domestic manufacturing industry can not meet the growing demand for hard alloy cutting tools, forming the vacuum in the high-end market, is dominated by foreign enterprises.

- Q: Carbide coated drill bit. Do you have one there?

- 1. carbide drills are generally worn in the back. Then it has little influence on service life.2., the high strength of the workpiece material, easy to cause the front of the drill (spiral groove) wear, bit life impact.

- Q: We'll drill on the stainless steel column. Which bit is better?

- Carbide drills are suitable for high speed steel

- Q: What does American standard cemented carbide grain size C mean?

- Then, when the mixture is granulated and pressed and heated to a point near the bonding metal (1300~1500 DEG C), the eutectic alloy is formed by the hardening and bonding of the metal. After cooling, the hardened phases are distributed in a grid of bonded metals that are closely related to each other and form a solid whole. The hardness of cemented carbide depends on the content of the hardened phase and grain size. The higher the content of the hardened phase and the finer the grain, the greater the hardness. The toughness of cemented carbide is determined by bonding metal. The higher the bonding metal content is, the greater the bending strength is. The effect of grain size on the mechanical properties of metals has a curve diagram: the strength of both ends is large and the middle is low. Explain: the mechanical properties of single crystals are very good. The finer the grain, the better the mechanical properties, but the mechanical properties of the single crystal with infinite size are much better than the grain's infinitesimal! A lot of grain size control method, the main principle of two: 1, increase the metal crystallization undercooling of 2, increase the crystal nucleus specific methods: electromagnetic stirring, adding grain refiner (such as Aluminum Alloy plus Al-Ti-C master alloy as grain refiner), lower solidification temperature, and fine grain of alloy elements and so on many.

- Q: K carbide carbide cutting tools, mainly used for turning what materials?

- K class brand is the international standard ISO code, equivalent to China's class YG carbide brand, suitable for processing stainless steel, non-ferrous metals and alloys, as well as non-metallic materials, cast iron and other materials.Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.Hard alloy is widely used as a tool material, such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials.

- Q: What are the types and types of carbide inserts?

- Your question is really not a simple answer can be got, to see you on what to divide, the blade types according to use classification, can also according to the material classification, and so on, I suggest you go to the official website of Zhuzhou China tungsten alloy has a hard alloy technology knowledge base to see. There's an introduction.

Send your message to us

Magnesium Plate Hardox400 Plate Printing Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords