Made In China 4330 Valve Rod Of High Quality

- Loading Port:

- Shanghai, China

- Payment Terms:

- L/C,T/T,Western Union,MoneyGram

- Min Order Qty:

- 2 Metric Tons m.t.

- Supply Capability:

- 20000 Metric Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

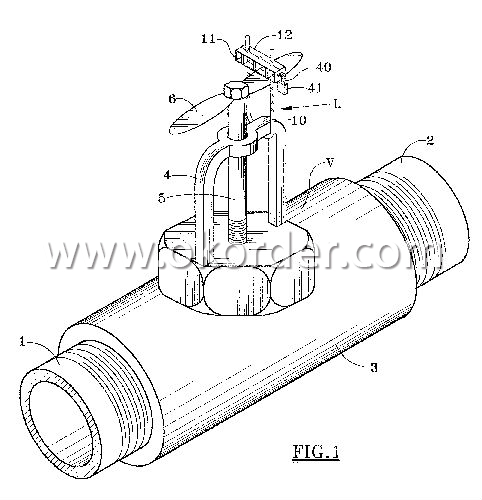

Specifications of Made In China 4330 Valve Rod Of High Quality

1.4330 forged valve rod

2.Min Outside Diameter: around 100mm

3.Weight of single: between 50kg and 5tons.

4.Material: 20CrMn,42CrMo,20#,45# etc.

5.Customized: OEM & ODM are welcome

Applications of Made In China 4330 Valve Rod Of High Quality

Many of Made In China 4330 Valve Rod Of High Quality are used in machinery and equipment, oil chemical industry components

Packaging & Delivery of Made In China 4330 Valve Rod Of High Quality

Packaging Detail:

Wooden package Non fumigation should be suitable for sea and land transportation. So parts be packed by foam first and be loaded into carton, and then the cartones be loaded into wooden box with pallet(non-fumigation).

Delivery Detail:

Around one month from receiving the payment in advance. Besides, if the quantity is large, it depends.

Advantages of Made In China 4330 Valve Rod Of High Quality

* Manufactuer

* Founded in 1987,abundent experience in the manufacture of oil chemical industry forging

* We have 3 workshops occupie 20000 square meters, one is gear workshop, the second one is heat treatment workshop, the third one is machining workshop

* Low Price

* Country of Origin

* Quality Approvals

* Form E/F/A/B;CO;FTA,ETC

* Country of Origin

* Guarantee/Warranty

* Good Service

* International Approvals

* Product Performance

* Prompt Delivery

- Q: How much is the Ma six automatic transmission case?

- You can consult the local dealer or repair factory, the region is different, the price is not the same, Taobao can also see, I wish you a happy car, safe and safe

- Q: What is the body material of the solenoid valve?

- Solenoid valve body material is generally cast copper or ductile iron.Solenoid valve is an electromagnetic control of industrial equipment, is used to control the automation of the basic components of the fluid, is an actuator, not limited to hydraulic, pneumatic. Used in industrial control systems to adjust the direction, flow, speed, and other parameters of the medium. Solenoid valve with different circuits to achieve the desired control, and control accuracy and flexibility can be guaranteed.

- Q: Dry box body wave MAGOTAN what oil, what is the name of

- Booster oil on the line [car has problems, asked the car master. 4S shop professional technicians, 10 minutes to solve. ]

- Q: Valve classification according to the valve material which?

- Valves are classified according to valve material:Non metal valve: such as ceramic valves, glass steel valves, plastic valves, metal valves: such as cast iron valves, carbon steel valves, cast steel valves, low-alloy steel valves, high alloy steel valves and copper alloy valves etc..

- Q: How to remove the dark valve body?

- Knock the wall holes slowly with a screwdriver, and unscrew the cover by counter clockwiseUnscrew the bolt with the cross screwdriver, pull out the handle and turn the cover in counter clockwise direction.

- Q: 06 Buick Excelle automatic gearbox inside the body how much money

- Hello, this quotation is not allowed everywhere is not the same, I suggest you consult the local auto parts City, I hope my answer can help you, I wish you a happy car.

- Q: Site damage seriously. Transmission valve knock a piece. I can't get a fire. Is that why?

- If you do not damage the part of the circuit, but a little off the valve body, it should not lead to a direct cause of fire. Damage to the valve may cause the vehicle to be unable to walk.

- Q: Such as the title, is the mouth and grease, valve bottom drain valve was raised, however, is a small valve 90 degree rotation control, and pneumatic valve pressure tube small valve the same, which valve is used for what?

- Ball valve on the role of a small valve is: pressure relief, that is, through the control of the valve to achieve the control of ball valve pressure inside the body size.Valve is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure. Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves (201, 304, 316), chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

- Q: Once, when someone saw a CVT gearbox, there was a part called the valve body. The structure inside was like a labyrinth, and it was full of oil. What's the function of this part?

- The working principle of planetary gear transmissionAlthough torque converter can transfer and increase the engine torque, but the torque ratio is not large, the speed change range is not wide, it can not meet the needs of the vehicle working conditions. In order to further enlarge the torque, enlarge the range of speed change and improve the adaptability of the automobile, an auxiliary transmission is also installed behind the hydraulic torque converter with a stepped gear transmission. The gear transmission is mostly planetary gear.Planetary gear transmission is composed of planetary gear mechanism and clutch, brake and one-way clutch. Planetary gear bodies are usually composed of multiple planetary rows, and the number of planets is related to the number of gears. The shift actuator of the planetary gear transmission includes a shift clutch, a shift brake and a one-way switch.The shift clutch is a wet multi plate clutch. When the hydraulic pressure causes the piston to press the driving plate and the driven piece, the clutch engages; when the working fluid is discharged from the piston cylinder, the return spring causes the piston to retreat and the clutch is separated.The brake shift usually has two forms: one is the wet multi disc brake, and the structure of clutch is basically the same, the difference is used to connect the brake rotating parts and the transmission housing, the rotating parts can not rotate. Another form of the shift brake is the outer beam type belt brake. The one-way clutch of the planetary gear transmission is the same as the one-way clutch in the hydraulic torque converter.

- Q: The new single valve pressure test, pressure test, why need to be removed discharge valve on the valve body, put on.

- Because first to test the strength of the body, the pressure is rated pressure of 1.5 times, if you still use the relief valve, then here will leak pressure. So for.

1. Manufacturer Overview

| Location | Jiangsu,China (Mainland) |

| Year Established | 2001 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | 30.00% North America 5.00% Eastern Asia |

| Company Certifications | ISO 9001:2000;ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | shanghai |

| Export Percentage | 11% - 20% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Made In China 4330 Valve Rod Of High Quality

- Loading Port:

- Shanghai, China

- Payment Terms:

- L/C,T/T,Western Union,MoneyGram

- Min Order Qty:

- 2 Metric Tons m.t.

- Supply Capability:

- 20000 Metric Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches