LOW CARBON FERRO CHROME 60% FOR STEEL MAKING

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Ferro Chrome

Chrome is always used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized.Micro-Carbon ferro chorme is applied to making stainless, acid-resistant steel and heat resistant steel.

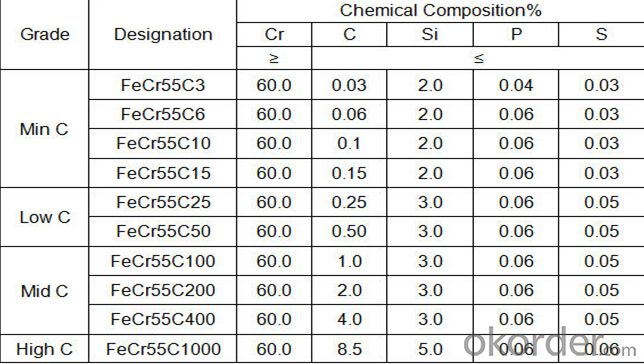

Specifications

Low Carbon Ferro Chrome

1. Original manufacturer

2. The stability of the shipments

3. Free samples

4. Relatively lower cost

Products information

1. It can be used to produce FerroChrome and Chrome metal in metallurgy industrial.

2. As a kind of steel addition,it is used to produce various special steels with high strength,corrosion resistance,anti-friction,thermostability and anti-oxydic.such as stainless steel,acid-resistant steel,heat-resistant steel,spring steel,tool steel and so on.

3. Chromite is used to produce Chrome brick,,Chrome-magnesium brick and other special refractories in fireproofing.

Packaging & Delivery

Packaging Detail: | 1MT/BAG |

Delivery Detail: | 15-30days |

- Q: What are the standard units of measurement for carbide inserts?

- Manufacturers usually use KG, which is used inside the shop

- Q: What brand of carbide is used in woodworking tools?

- Cemented carbide YG8/ has good toughness and good wear resistance. It is mainly used in drawing dies for wire and rod processing. At the same time, it is also suitable for rough cast, non-ferrous metal and its alloy, non ferrous metal, uneven surface and intermittent cutting, rough car, fine plane, fine milling, general hole and deep hole drilling, reaming and making woodworking tools, etc..

- Q: What are the main items of cemented carbide production process and finished products inspection, as well as the price of testing equipment, equipment and equipment?!! Please experts advice and answer, the younger brother will be grateful!!!!!!

- Fluorescence detection: fluorescence detectorScanning electron microscope: SEM scanning electron microscopeXRD: XRD testElectron microscopy: TEM projection electron microscopyMy school student, brother, I speak not all, you should all do so, detection cost is not expensive, but the equipment to buy it, not tens of millions of nabuxialai, and equipment is not the same.

- Q: Welding hard alloy cutter, hard alloy cutter, high speed steel, ceramic knife head head are what are the advantages and shortcomings?

- Long life, than the average speed of life only about 10 times, but the price is high, because the hard, so relatively crisp!

- Q: In addition to diamonds, Hunan there are no good carbide manufacturers? Product advantages in the ordinary blade, knife head and mining tools. Which factory's alloy is of good quality? The best size, with the original tungsten powder. Please know what to say, first thank you

- Looking for packing box manufacturers can find the letter plastic

- Q: Method for assembling hard alloy cold heading die

- If it is made of hard alloy cold die core and the steel bushing assembly, depends on the heat treatment hardness you cold die steel sleeve to be, if not steel heat treatment, direct heat bushing, the amount of interference for hard alloy core diameter of about 0.6%, if the steel heat treatment to HRC40 about the amount of interference for hard alloy core diameter about 0.3%.

- Q: Hello I remember carbide knives have several classifications As if it were not the same as it is now, can you tell me the same and different models as before? What material can they make?

- I remember Zhuzhou Hua tungsten. They have a full range of them. You can go to their Baidu company

- Q: What alloy tool can be used as hard alloy?

- At present, the world's best tool materials used for cutting high alloy steel is CBN, CBN is the world's second hard materialsThe hard material is diamond, but the chemical composition of diamond are carbon, in high temperature processing conditions, the carbon will react with iron, so the processing of diamond is not suitable for high alloy steels

- Q: What are the differences in performance between cemented carbide cutting tools and PCD cutters (polycrystalline diamond)?

- PCD has a very high hardness, but its toughness is not as good as carbide, much lower than high-speed steel, therefore, the main failure form of PCD cutting tool is cutting edge.PCD cutters can effectively process non-ferrous metal materials and non-metallic materials. Such as copper, tungsten and other non-ferrous metals and their alloys, ceramics, hard alloy, various fiber and particle reinforced composite materials, plastics, rubber, graphite, glass and wood, but the diamond is not suitable for cutting steel and other iron materials.

- Q: What is the base material of carbide saw blade?

- Base material of carbide saw blade1., 65Mn spring steel, good elasticity and plasticity, material economy, heat treatment, hardenability, and its heating temperature is low, easy to deformation, can be used for cutting requirements of the blade is not high.2. carbon tool steel with high carbon content, high thermal conductivity, but by 200 degrees -250 degrees Celsius temperature, its hardness and wear resistance decreased rapidly, heat treatment deformation, hardenability, tempering time is long, easy to crack. Manufacture economical materials for cutting tools, such as T8A, T10A, T12A and so on. 3. alloy tool steel, compared with carbon tool steel, has good heat resistance, good wear resistance, good treatment performance, heat-resistant deformation temperature of 300 degrees -400 degrees, suitable for manufacturing high-grade alloy circular saw blade.4. high speed tool steel has good hardenability, hardness and rigidity, less heat distortion, ultra high strength steel, thermoplastic stability, suitable for manufacturing high-grade ultra-thin saw blade.

Send your message to us

LOW CARBON FERRO CHROME 60% FOR STEEL MAKING

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords